Traction-driven mulch recycling machine

A traction drive, recycling machine technology, applied in the fields of collectors, agricultural machinery and implements, agriculture, etc., can solve the problem of incomplete film collection, improve the success rate of film bonding, increase the number of film grabs, and improve the grab rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

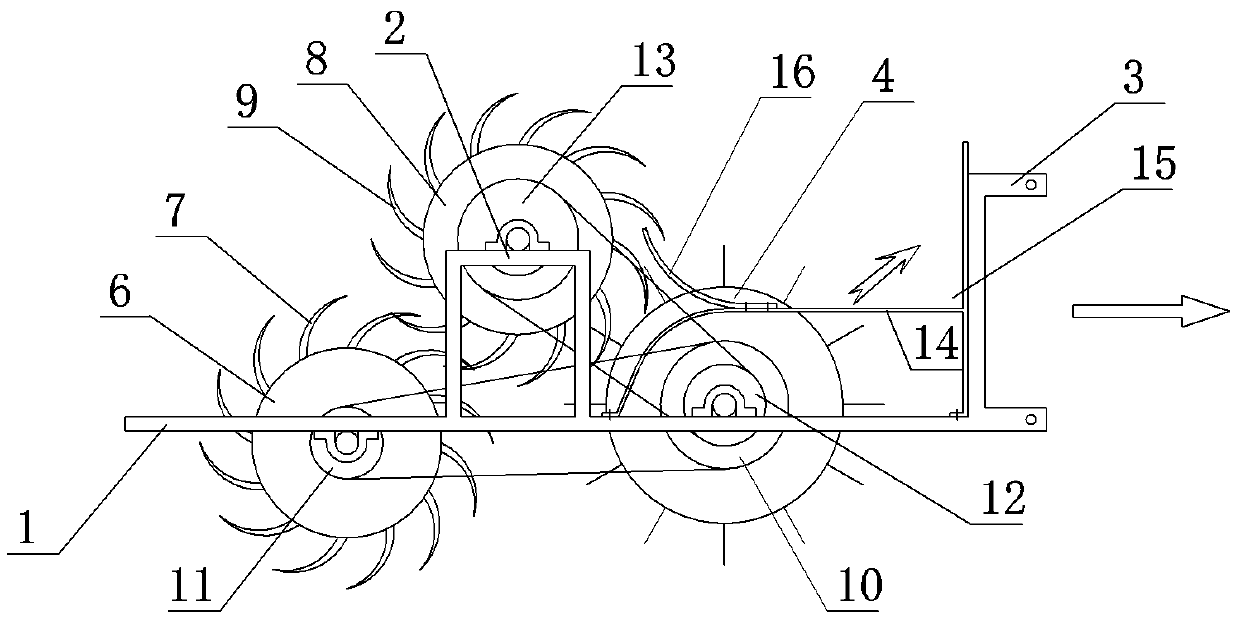

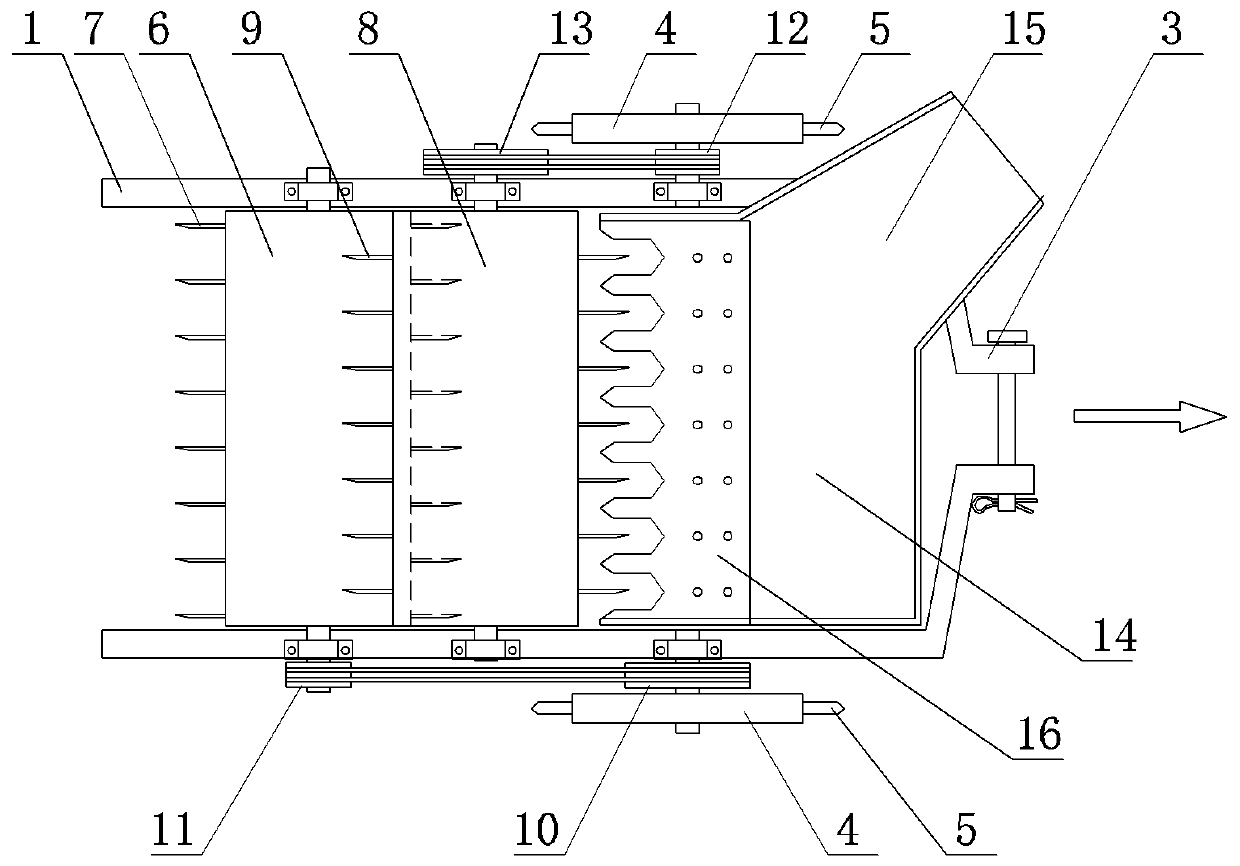

[0020] Example: a traction-driven plastic film recovery machine, see figure 1 and figure 2 , the vehicle frame is provided with a bottom beam 1 and a roof beam 2, and a traction end 3 is provided, and the traction end 3 is driven forward by the tractor.

[0021] A film grabbing roller 6 is mounted on the vehicle bottom beam 1 through a bearing, and a film receiving roller 8 is mounted on the vehicle roof beam 2 through a bearing. The outer surfaces of the film grabbing roller 6 and the film joining roller 8 are respectively provided with film grabbing teeth 7 and film joining teeth 9 . like figure 1 As shown, the rotation directions of the film grabbing roller 6 and the film contacting roller 8 are the same, and the arcuate directions of the film grabbing teeth 7 and the film contacting teeth 9 are the same. The film-grabbing teeth 7 and the film-contacting teeth 9 may be arc-shaped, broken-line or arc-shaped.

[0022] The installation distance between the film grabbing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com