Methods and apparatus for constructing glass furnace structures

A technology of refractory structures and components, applied in glass furnace equipment, supporting structures, transportation and packaging, etc., can solve problems such as installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

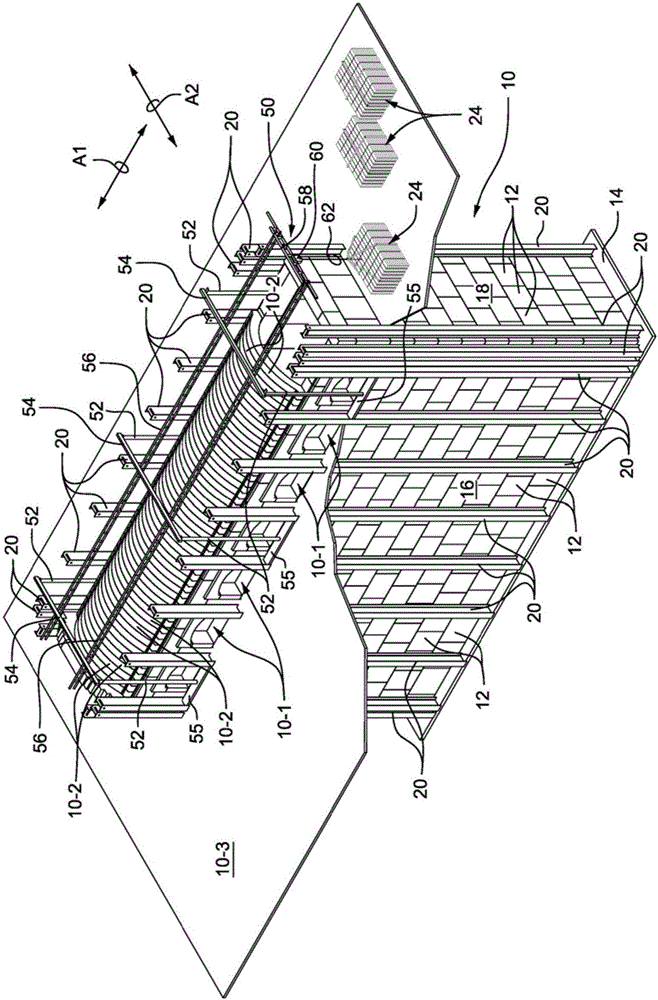

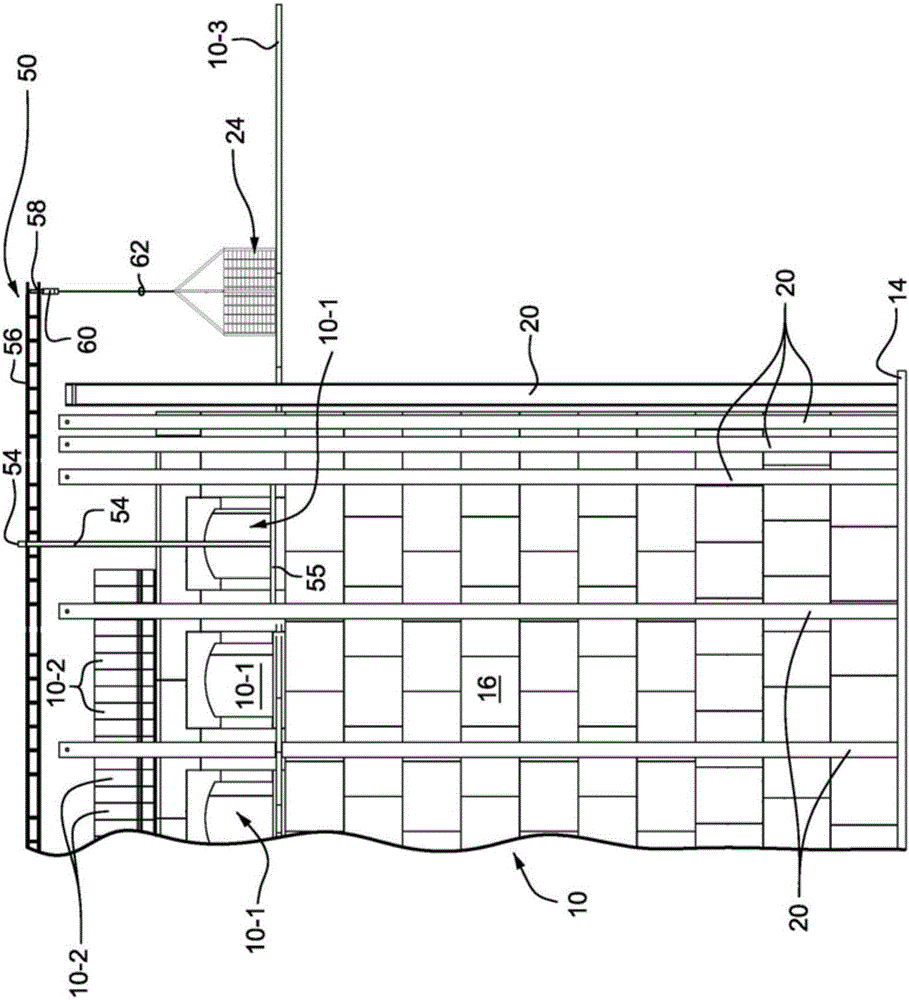

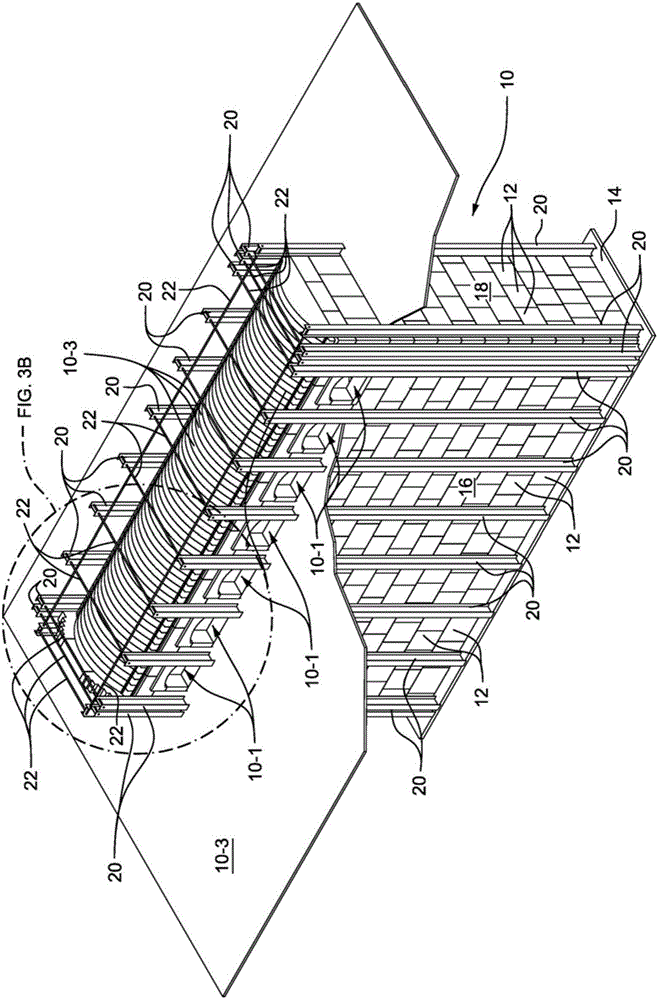

[0036] Attached figure 1A perspective view of the regenerator structure 10 is schematically depicted, showing an overhead crane arrangement 50 in accordance with an embodiment of the invention. As shown, the regenerator structure 10 is constructed of large prefabricated refractory blocks, several of which are indicated by reference numeral 12, stacked on a base 14 to form side walls 16 and end walls 18, respectively. It should be understood that the regenerator structure 10 is used in conjunction with a glass melting furnace (not shown) in operation. The regenerator structure 10 generally depicted in the drawings is of the type used in side-fired glass melting furnaces. However, the attributes of the embodiments of the invention to be described herein are equally applicable to other glass melting furnace designs, such as end-fired glass melting furnaces.

[0037] The regenerator structure 10 includes a series of ports 10-1 for introducing preheated combustion air into a glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com