Sound cavity structure and mobile terminal

A sound cavity and front cavity technology, applied in the field of sound cavity structure and mobile terminals, can solve the problems of long mold manufacturing cycle, large workload, and cumbersome manual work, so as to reduce the production cost, ensure the sealing performance, and ensure the sealing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

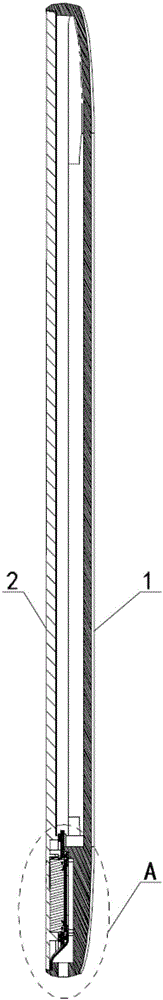

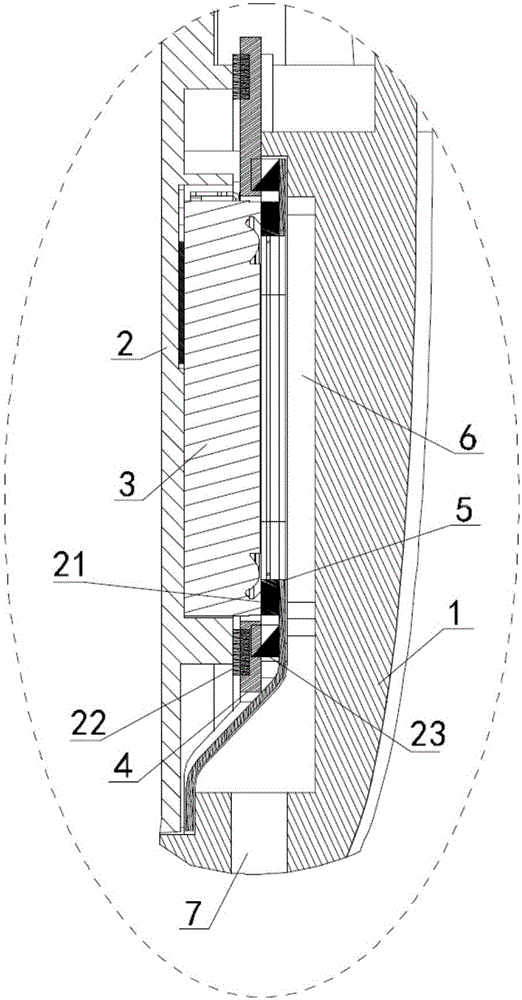

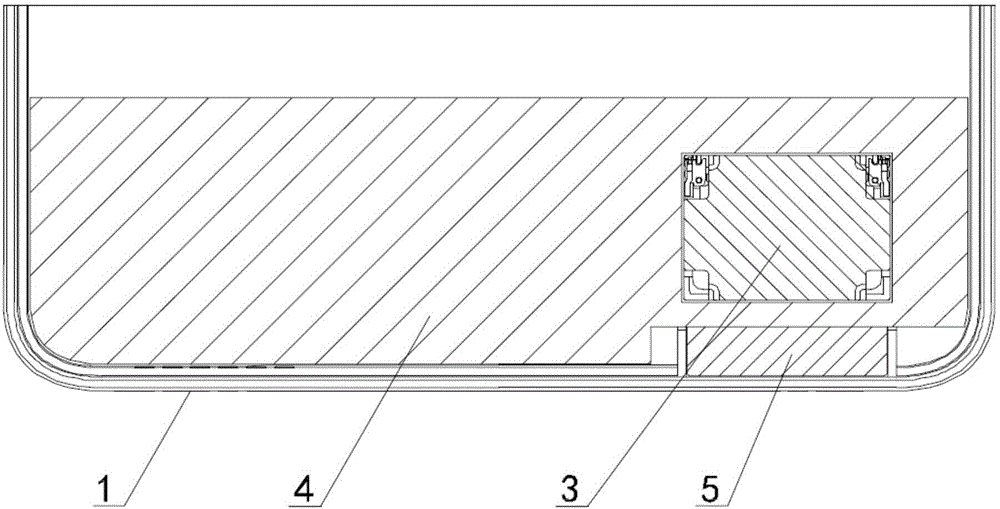

[0045] combine Figure 1-Figure 6 As shown, a sound chamber structure provided in Embodiment 1 of the present invention may include: a housing and a circuit board 4, a speaker 3, and a support plate 5 disposed inside the housing; the housing includes a first housing 1, The second housing 2 and the loudspeaker 3 are installed on the circuit board 4; wherein, the first housing 1 is provided with a sound outlet hole 7 passing through the first housing 1, and the inner side of the first housing 1 is provided with the sound outlet hole 7. The front chamber channel 6; the inner side of the second housing 2 is provided with a groove for accommodating the speaker 3; in specific operation, the above-mentioned speaker 3 can be installed on the circuit board 4, and the basic circuit connection of the speaker 3 can be completed.

[0046] Further, the support plate 5 has a hollow channel, one side of the support plate 5 is the first side 52 connected to the outer edge of the port of the fr...

Embodiment 2

[0060] The substantial difference between the second embodiment and the first embodiment is that: a first positioning structure is also provided;

[0061] combine Figure 7 As shown, the sound chamber structure provided in the second embodiment of the present invention has a main structure similar to that of the first embodiment, and also includes: a housing and a circuit board 4, a speaker, and a support plate arranged inside the housing; the housing includes interconnected The first shell 1, the second shell, and the speaker are installed on the circuit board 4; the first shell 1 is provided with a sound hole that runs through the first shell 1, and the inside of the first shell 1 is provided with a sound hole that communicates with the sound hole. The front chamber channel; the inner side of the second housing is provided with a groove for accommodating the loudspeaker; the support plate has a hollow channel, one side of the support plate is the first side connected to the ...

Embodiment 3

[0067] The substantial difference between the third embodiment and the first embodiment is that: there is also a second positioning structure;

[0068] In the sound chamber structure provided in the third embodiment of the present invention, the main structure is similar to that of the first embodiment. For the sealing form of the cavity and the rear sound cavity, and the assembly operation of the sound cavity structure, please refer to the records in the first embodiment above. The third embodiment aims to illustrate the specific setting of the second positioning structure.

[0069] In this embodiment, a second positioning structure is provided between the above-mentioned circuit board and the speaker; through the setting of the above-mentioned second positioning structure, the convenient assembly operation and precise installation operation of the speaker and the circuit board can be effectively guaranteed; Poor contact caused by errors can effectively ensure the overall rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com