Pairing dual-contact connector and PCB board connection structure

A PCB board and double-contact technology, which is applied in the direction of connection, parts of the connection device, contact parts, etc., can solve problems such as unstable connection, inconvenient operation, and complicated structure, and achieve convenient and stable electrical connection and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

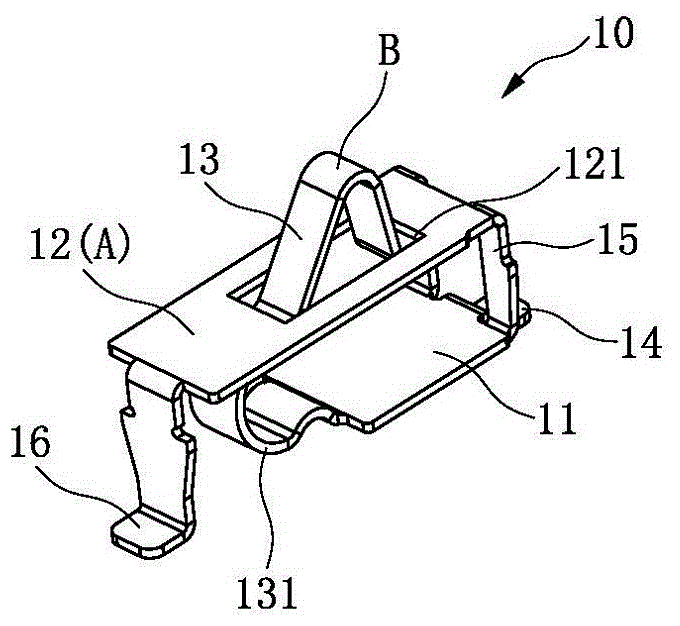

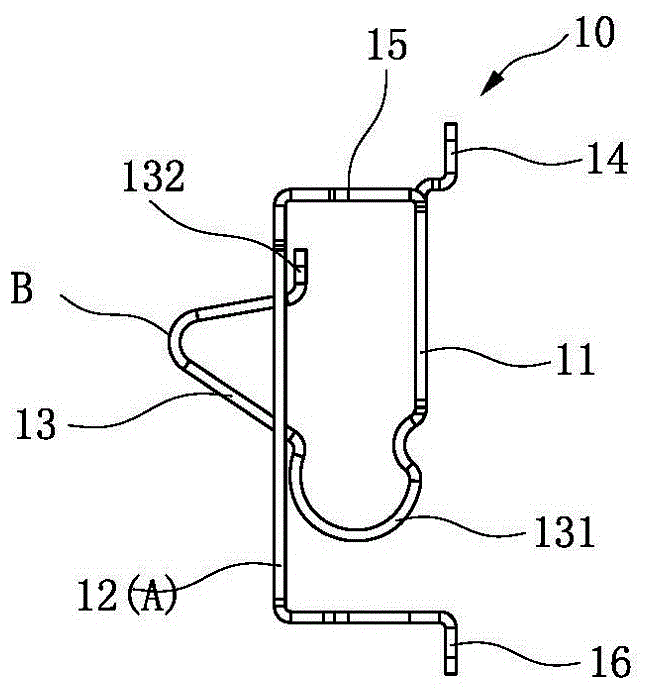

[0035] Embodiments 1 and 2: the lower substrate 11 is short and the upper elastic plate 12 is long, and the other end of the substrate 11 under the frame body 10 forms a first electrical pin 14 outward (the first embodiment is a welding leg, and the second embodiment is a pin) , the other end of the base plate 11 under the frame body 10 forms a bracket 15 upwards, the upper end of the bracket 15 is connected to the other end of the upper elastic plate 12, and the upper elastic plate 12 covers the lower base plate 11 and the elastic piece 13, because the upper elastic plate 12 is long enough , the upper elastic plate 12 corresponds to the second contact B to form a through hole 121 for the second contact B to pass through, and one end of the upper elastic plate 12 is bent downward to form a second electrical pin 16 (the first embodiment is a welding leg, the implementation Example 2 is a pin), the elastic piece 13 extending from one end of the substrate 11 under the frame body 1...

Embodiment 3 4

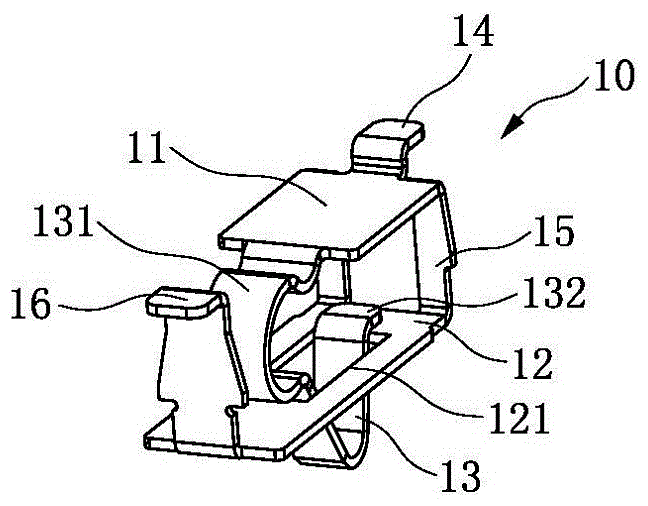

[0037] Embodiments 3 and 4: the lower substrate 11 is long and the upper elastic plate 12 is short, and the other end of the substrate 11 under the frame body 10 forms a first electrical pin 14 outward (the third embodiment is a welding leg, and the fourth embodiment is a pin) The other end of the base plate 11 under the frame body 10 forms a bracket 15 upwards, and the upper end of the bracket 15 is connected to the other end of the upper elastic plate 12, because the upper elastic plate 12 is relatively short, and the elastic piece 13 extending from one end of the base plate 11 under the frame body 10 A hook 132 is formed at the end, which can just be hooked on one end edge of the upper elastic plate 12 to limit the position of the elastic piece 13 .

[0038] The double-contact connector 100 of the third and fourth embodiments can be equipped with a rubber core 20, which can facilitate the side-by-side assembly of multiple double-contact connectors 100. The rubber core 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com