Sound absorption and insulation structure for silencing device

A sound-absorbing device and sound-absorbing and insulating technology, which is applied in the direction of sound-emitting devices and instruments, can solve problems such as insufficient sound-absorbing volume, vibration, and thickened sound-absorbing and insulating structures, and achieve the effect of light weight and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

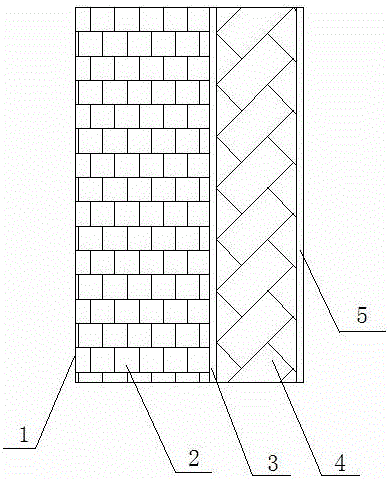

[0013] Such as figure 1 As shown, a sound-absorbing and insulating structure for a sound-absorbing device at least includes sequentially connected armor layer 1, sound-absorbing layer 2, sound-insulating layer 3, energy-dissipating layer 4, and outer panel 5. By adjusting the thickness of the sound-absorbing layer 2 , increase the number of combined structures of the sound-insulating layer 3 and the energy-dissipating layer 4, and increase the sound-absorbing volume by 10 to 60db.

[0014] The sound-absorbing layer 2 is composed of a keel of the sound-absorbing layer and a sound-absorbing material filled in the keel.

[0015] The sound insulation layer 3 is various boards or various sound insulation materials.

[0016] Preferably, the sound insulation layer 3 is composed of a sound insulation frame and a rubber felt board.

[0017] The energy-dissipating layer 4 is composed of sound-absorbing cotton and keels.

[0018] The above-mentioned structure can add energy-dissipatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com