Method of simulating generating of large depth field programmable grating

A grating and depth-of-field technology, applied in the field of optical detection, can solve the problems of limited three-dimensional measurement range, fixed projection pattern, inflexible use, etc., to achieve the effect of improving three-dimensional measurement accuracy, expanding depth of field, and improving measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

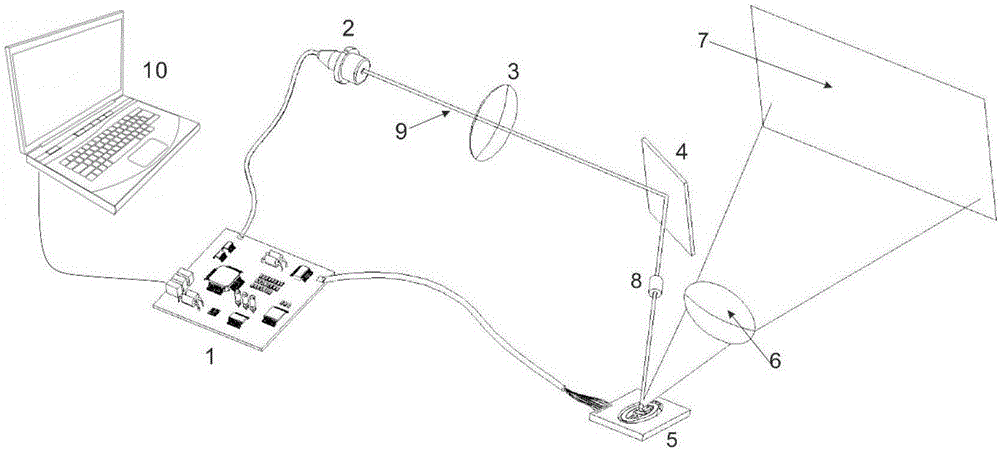

[0039]The present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] The technical solution is:

[0041] The first step is to design the working parameters of the system. Determine the maximum working distance L according to the working distance of the grating 2 , the minimum working distance L 1 ; the maximum spot ω of ΔL within the depth of field max ; The number M of lines scanned by a single frame raster image, M is determined by the characteristics of the laser beam.

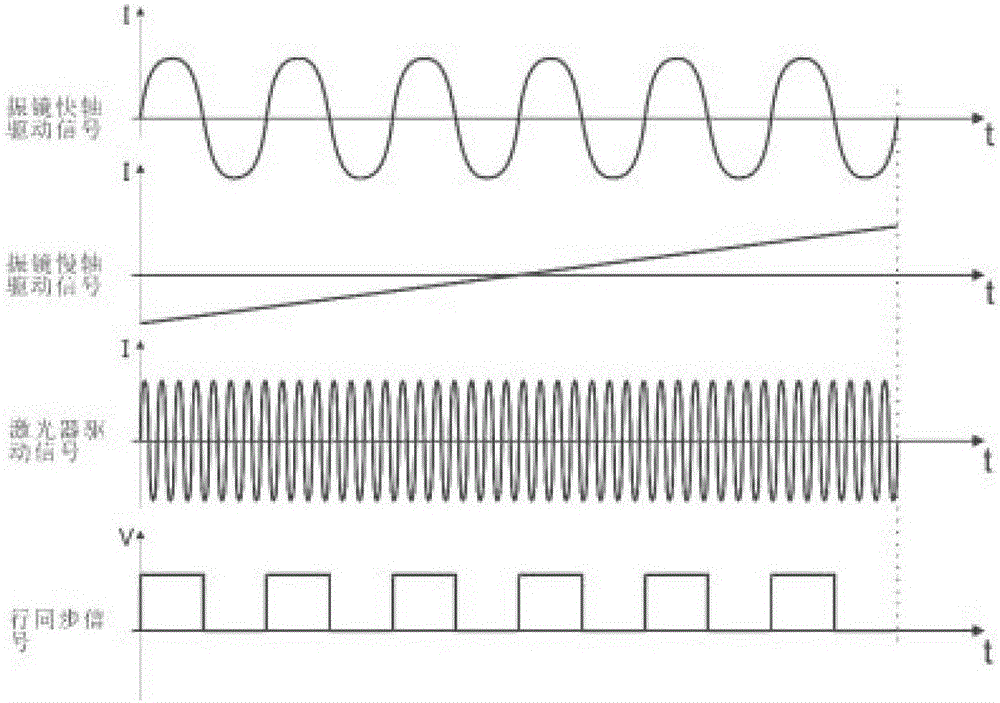

[0042] The second step is to generate the driving signal. There are three types of drive signals involved. 1) MEMS scanning galvanometer fast axis drive signal, which is a current signal of sine (or cosine) waveform, its frequency f x Equal to the resonant frequency f of the fast axis direction of the MEMS scanning galvanometer, its peak-to-peak value I x峰峰 Determined by the parameters of the MEMS galvanometer. 2) The slow axis drive signal of the MEM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com