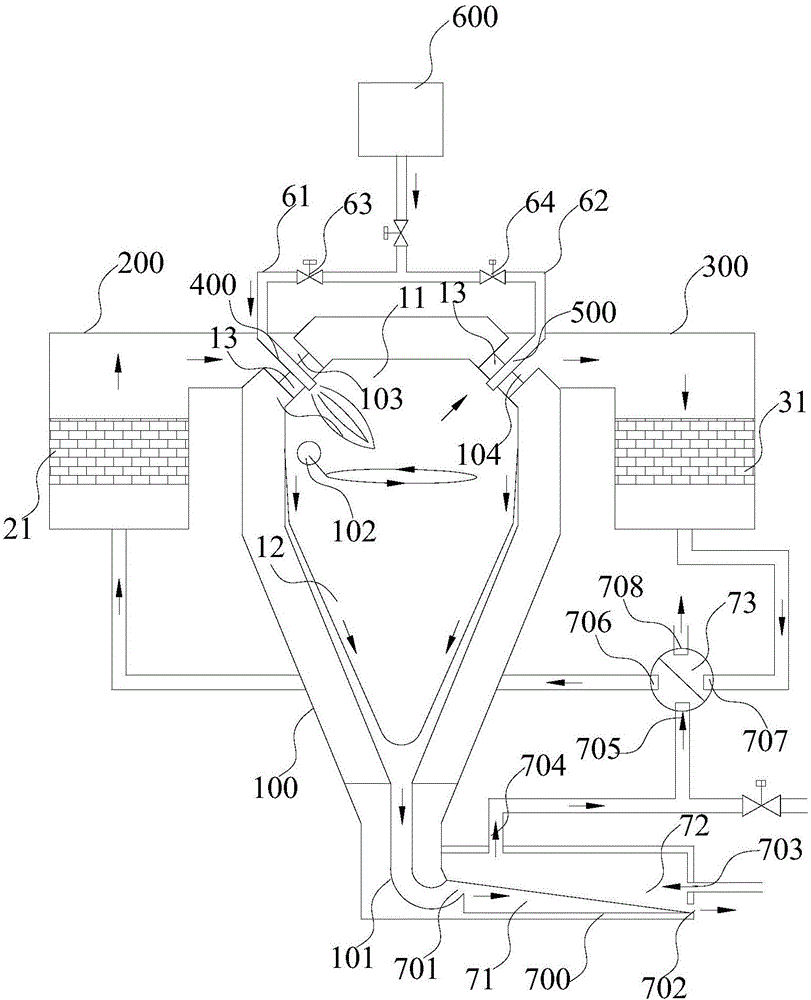

Heat-accumulating-type fly ash gasification smelting furnace

A gasification melting and melting furnace technology, applied in the field of solid waste recycling, can solve the problems of high energy consumption and poor melting effect, and achieve the effects of uniform material distribution, energy saving and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

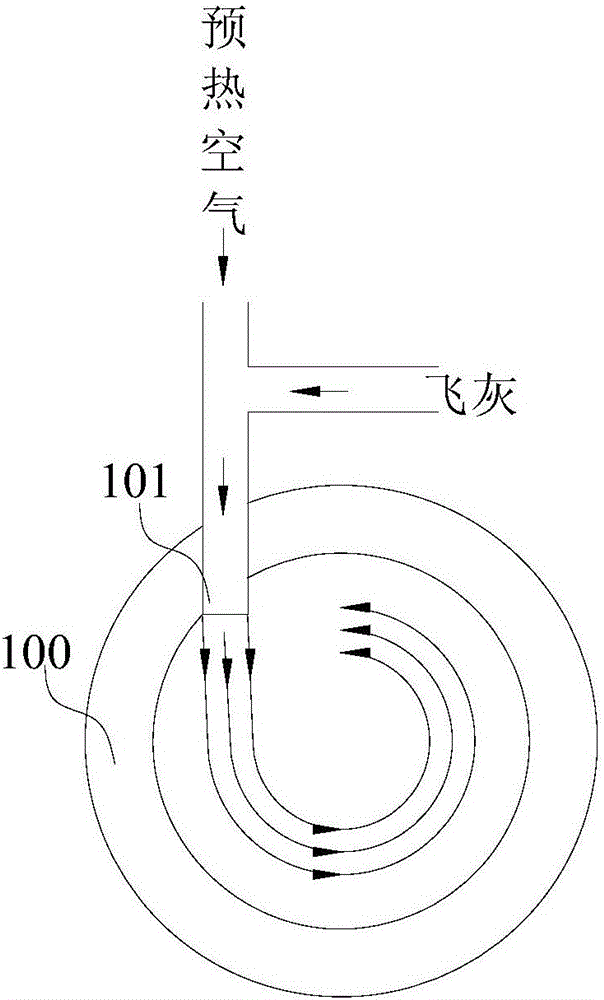

Method used

Image

Examples

Embodiment 1

[0058] The toxic equivalent (I-TEQ) of dioxin in the fly ash produced by the fluidized bed incinerator is 3.7ng / g. The fly ash gasification and melting furnace in the regenerator of the application is used to process the fly ash and control the melting in the furnace. The temperature is 1400 degrees Celsius, and then the indicators such as dioxins in the flue gas discharged from the melting furnace are detected (refer to Table 1). Negative impact.

[0059] Table 1 Changes of dioxins in slag before and after fly ash treatment

[0060] project fly ash slag Dioxins (ng / g) 320 0.012 Dioxin Toxic Equivalent (ng-TEQ / g) 3.7 0.00049

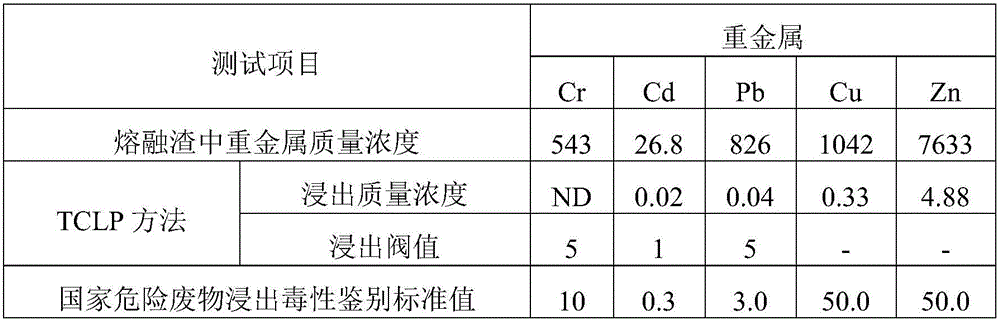

[0061] It can be seen from Table 2 that during the melting process, the fixation rates of heavy metals Cr and Zn are higher, while the fixation rates of volatile heavy metals Cu, Pb and Cd are lower. The leaching toxicity of molten slag is much lower than the limit value of the national identification standard for leachi...

Embodiment 2

[0066] The toxic equivalent (I-TEQ) of dioxin in the fly ash produced by the fluidized bed incinerator is 6.7ng / g. The fly ash gasification and melting furnace in the regenerator of the application is used to process the fly ash and control the melting in the furnace. The temperature is 1700 degrees Celsius, and then the indicators such as dioxins in the flue gas discharged from the melting furnace are detected (see Table 3). The removal rate of dioxins exceeds 99%, which is far below the emission standard and will not cause environmental pollution Negative impact.

[0067] Table 3 Changes of dioxins in slag before and after fly ash treatment

[0068] project fly ash slag Dioxins (ng / g) 640 0.004 Dioxin Toxic Equivalent (ng-TEQ / g) 6.7 0.00066

[0069] It can be seen from Table 4 that the main components of the resulting molten slag are CaO, Al 2 o 3 and SiO 2 , and its content accounts for about 99% of the total mass. And the higher content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com