Centrifugal pumps, impellers for convenient measurement of pressure pulsation of centrifugal pump blades

A technology for convenient measurement and vane pressure, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems such as the inability to easily measure the pressure pulsation of centrifugal pump vanes, to prevent detachment from the impeller, reduce The effect of small fluid disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0033] The centrifugal pump provided in this embodiment uses the impeller described in Embodiment 1, which can conveniently measure the blade pulsation pressure.

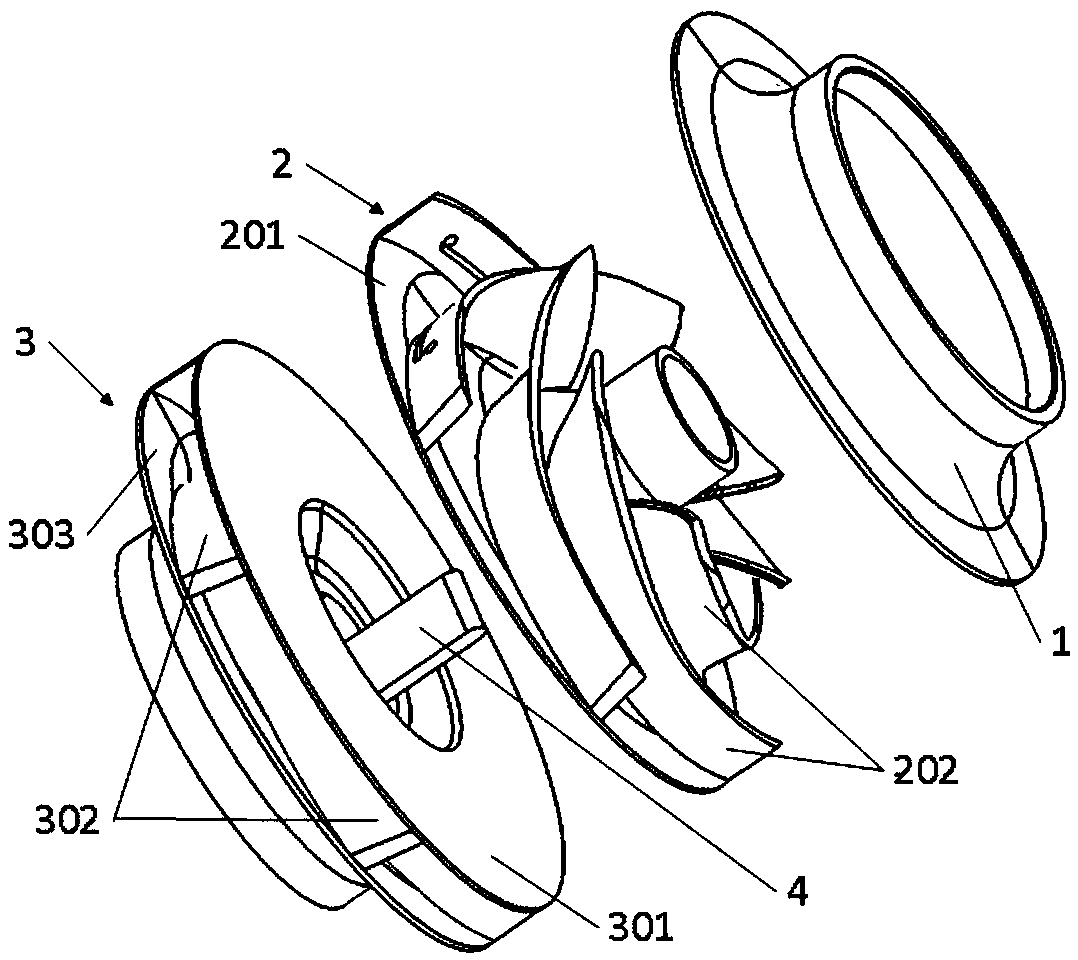

[0034] The centrifugal pump provided in this embodiment is a double-suction centrifugal pump, including the impeller described in Embodiment 1, namely figure 1 The right half of the impeller shown in , called the first impeller, also includes figure 1 The left half impeller shown in is called the second impeller 3. The structure of the second impeller 3 is basically similar to that of the first impeller, except that the second impeller 3 is processed by integral casting, that is, the blade and the end cover 1 are integrally processe...

Embodiment 3

[0037] An embodiment of the present invention also provides a centrifugal pump, including the above-mentioned impeller for measuring the pressure pulsation of the blades of the centrifugal pump. The centrifugal pump can be a double-suction pump, adopting two identical above-mentioned impellers, and the two dividing plates of the impellers are installed oppositely, or only one above-mentioned impeller can be used, such as being made into a single-suction centrifugal pump.

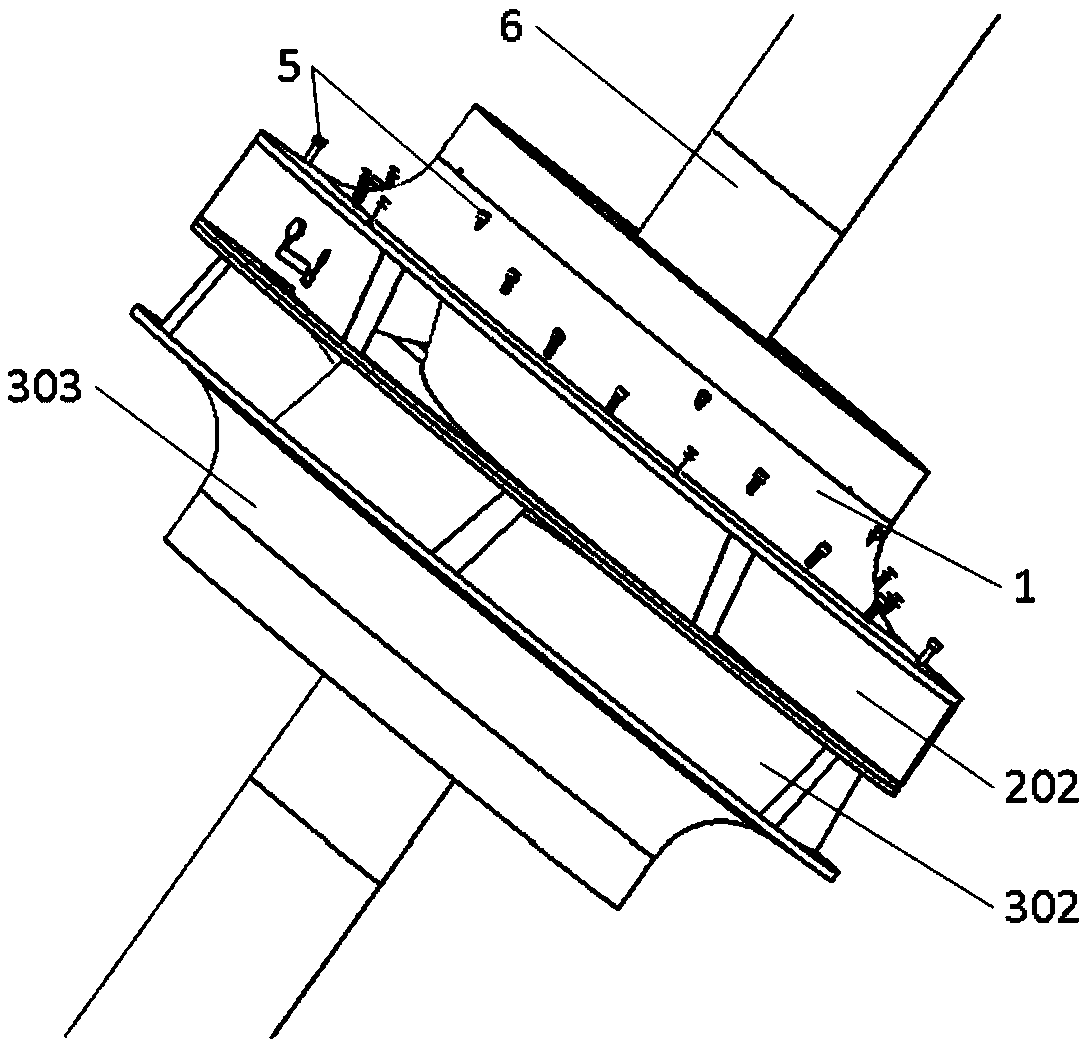

[0038] Wherein, it also includes a second pump shaft 6, the impeller is sleeved on the second pump shaft 6, the second pump shaft 6 is provided with a shaft hole 602, and the side wall of the second pump shaft 6 is provided with the shaft hole 602 Connected radial holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com