Sliding rod type switch for fuel machine

A sliding rod type, fuel technology, applied in combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve engine damage, affect engine performance and life, affect engine use, etc., to protect the engine, ensure normal operation, avoid The effect of mixed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

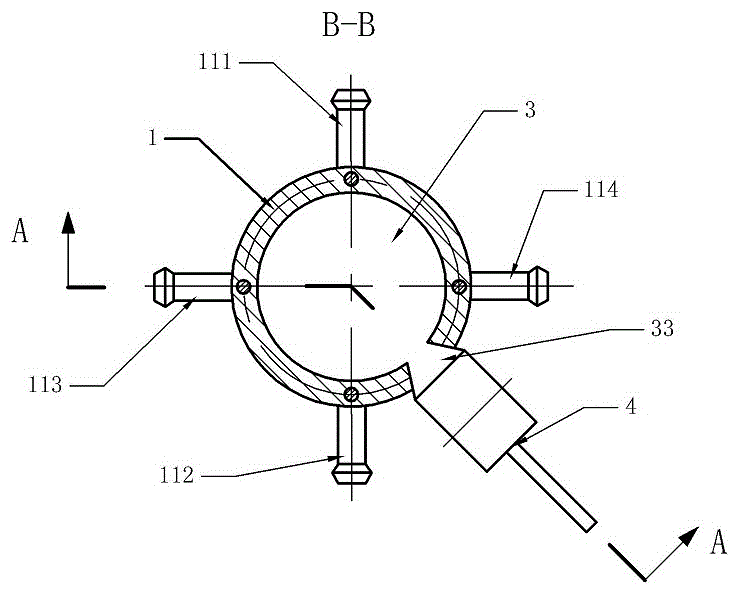

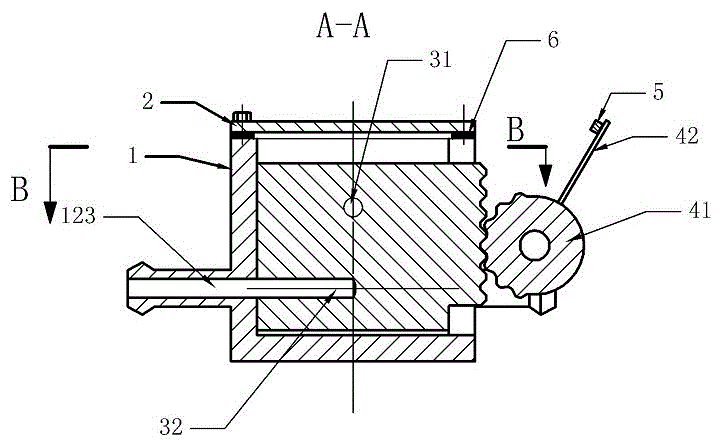

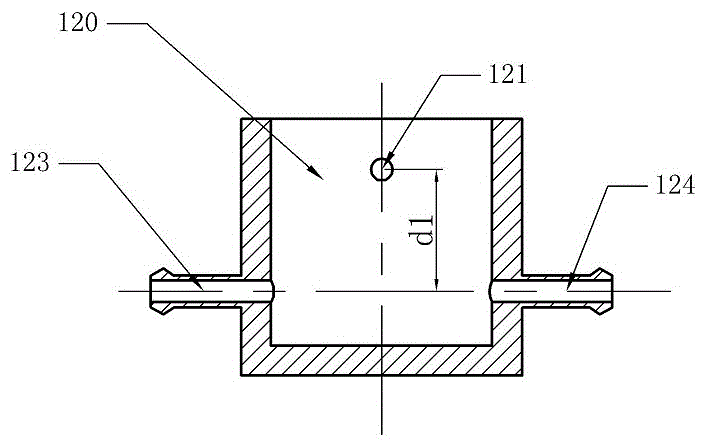

[0026] The reference signs in the drawings of the specification include: switch base 1, cover plate 2, oil inlet joint 111, oil outlet joint 112, air intake joint 113, air outlet joint 114, accommodation tank 120, oil inlet hole 121, oil outlet hole 122, air intake hole 123, air outlet hole 124, control rod 3, oil groove 31, air groove 32, handle 4, chute 13, slide block 33, disc body 41, handle 42, limit piece 5, gasket 6.

[0027] The slide bar switch of the fuel engine provided in this embodiment, the overall structure is as follows figure 1 and figure 2 As shown, it includes a switch base 1, a cover plate 2, a control rod 3 and a handle 4. On the side wall of the switch base 1, an oil inlet joint 111, an oil outlet joint 112, an air intake joint 113 and an air outlet joint 114 are arranged. structured as image 3 and Figure 4 As shown, the switch base 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com