Repeated-free-support temporary support equipment

A temporary support and equipment technology, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., to achieve the effect of convenient and safe connection, ensuring stability and improving personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

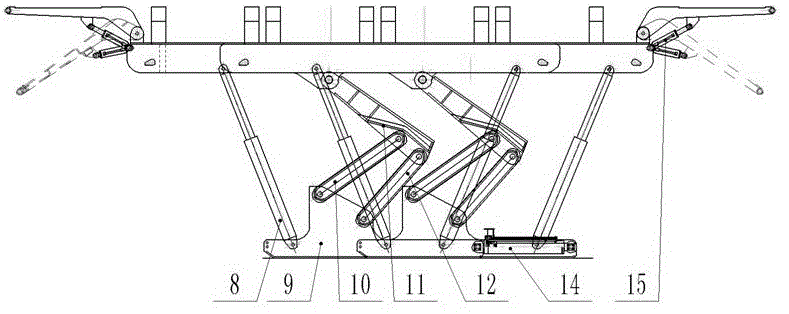

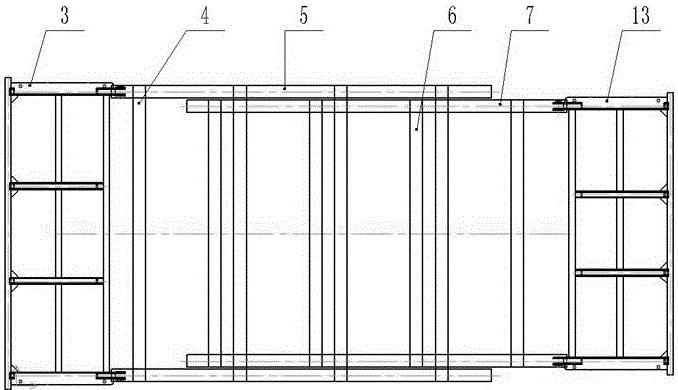

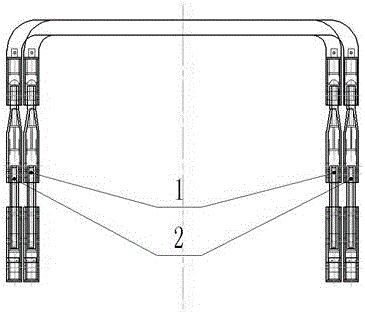

[0030] A temporary support device without repeated support, comprising an inner bracket group 1 and an outer bracket group 2, the inner bracket group 1 is arranged inside the outer bracket group 2, the inner bracket group 1 includes two left and right inner brackets, and the two inner brackets pass through the inner bracket The group cantilever beam 13 and the middle support crossbeam 6 connect the left and right inside inner brackets as a whole, and the inner bracket group cantilever beam 13 is hingedly connected to the two ends of the inner bracket; the outer bracket group 2 includes two left and right outer brackets, and the outer bracket passes through The outer support group cantilever 3 and the middle support beam 4 connect the left and right outer outer supports as a whole, and the outer support group cantilever 3 is hingedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com