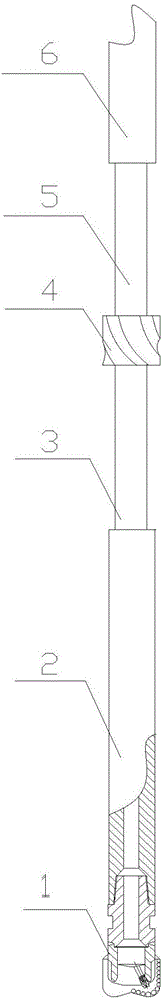

High WOB anti-deviation well straightening drill assembly

A drilling tool assembly and deviation prevention technology, which is applied to drill pipes, drill pipes, directional drilling, etc., can solve the problems of complex results and increase manufacturing costs, and achieve obvious deviation prevention effect, excellent effect, and favorable drilling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

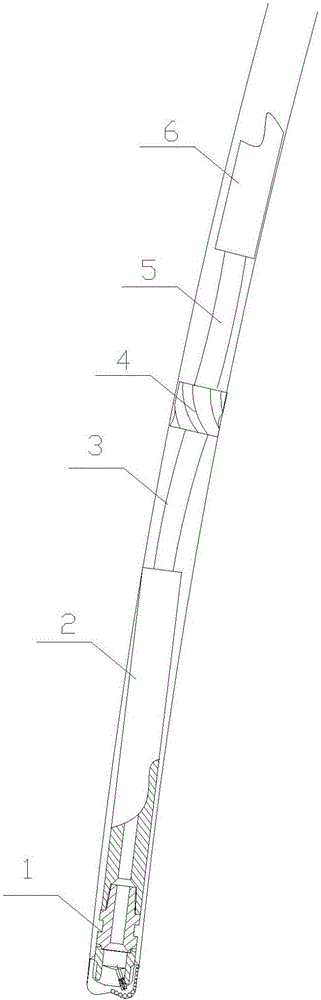

[0035] Embodiment one: Utilize above-mentioned drilling tool combination to carry out drilling operation in the wellbore of descending trend, when drilling, see figure 2 , the centralizer 4 acts as a fulcrum, used as a fulcrum, the upper thick drill collar 6 lies on the lower well wall, so that the upper thin drill collar 5 bows down in the middle, and the bottom rises, and the lower thin drill collar 3 bows in the middle, and the bottom hangs down, so that While the drill bit 1 bears the pendulum force of the lower coarse drilling tool 2, the drilling direction points to the descending direction, so as to apply a strong pendulum force to the drill bit and make the positive cutting surface of the drill turn to the descending direction to jointly prevent deflection and correct the deflection.

Embodiment 2

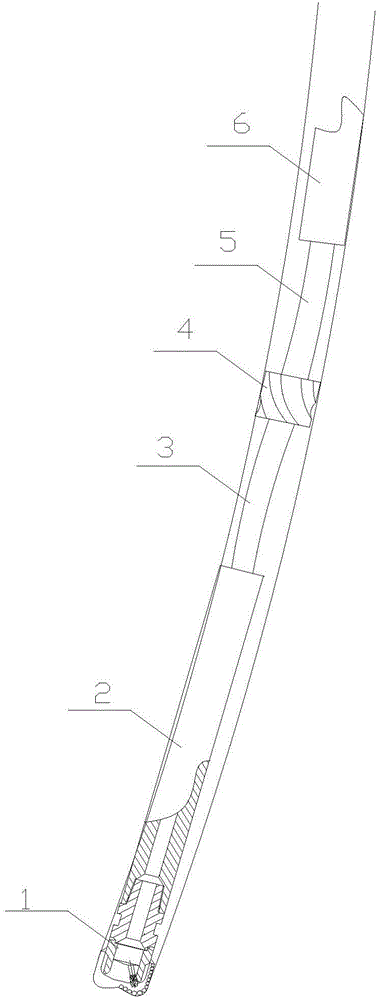

[0036] Embodiment two: Utilize above-mentioned drilling tool assembly to carry out drilling operation in the borehole of increasing deviation trend, when drilling, see image 3 , the centralizer 4 acts as a fulcrum, used as a fulcrum, the upper thick drill collar 6 lies on the lower well wall, so that the upper thin drill collar 5 bows down in the middle, and the bottom rises, and the lower thin drill collar 3 bows in the middle, and the bottom hangs down, so that While the drill bit 1 bears the pendulum force of the lower coarse drilling tool 2, the drilling direction points to the descending direction, so as to apply a strong pendulum force to the drill bit and make the positive cutting surface of the drill turn to the descending direction to jointly prevent deflection and correct the deflection.

Embodiment 3

[0037] Embodiment 3: Drilling operations are carried out in a straight wellbore by using the above-mentioned drilling tool assembly. During drilling, the lower thin drill collar 3 and the upper thin drill collar 5 are bent, so that the drilling tool assembly is in a vortex state. Drilling field application shows that the whirl state of the bottom hole assembly has the effect of preventing deviation and straightening. Therefore, when operating in a straight borehole, the above-mentioned drilling tool assembly of the present invention has the effect of preventing deviation and straightening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com