Tunnel drilling-blasting construction, tunneling and risk elimination apparatus and method of using same

A drilling device and drilling and blasting technology are applied in drilling equipment and methods, supporting devices, drilling with mechanical conveying devices, etc. The effect of saving the required time, reducing labor intensity, and convenient operation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

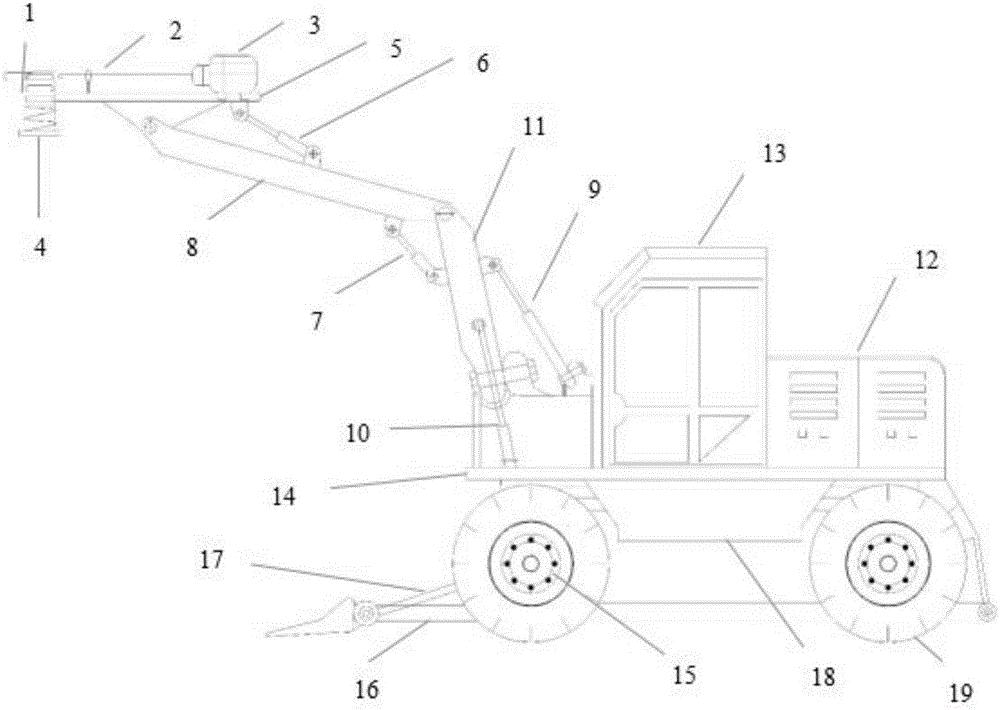

[0029] Below in conjunction with accompanying drawing and specific embodiment, a kind of drilling and blasting construction excavation of the present invention and the mechanical device for eliminating danger will be further described:

[0030] Such as figure 1 and figure 2 As shown, in a specific embodiment, the present invention includes a traveling device, a slewing device, a boom device, a hydraulic crushing drilling device, and a dust treatment system; the present invention is a tunnel that integrates functions of risk removal, drilling, and charge Drilling and blasting construction excavation and risk elimination machinery has high degree of automation, good flexibility, high safety, simple and convenient operation, and reasonable system function setting, which effectively improves work efficiency and greatly saves construction time. It is applicable to various complex tunnels Environmental construction; the specific composition of each device is as follows:

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com