Construction method of roof photovoltaic strip foundation

A strip foundation and construction method technology, applied in basic structure engineering, roofing, roof covering and other directions, can solve the problems of cumbersome construction steps, difficult construction, slow construction progress, etc., to improve the quality and stability of the roof structure, solve The effect of uneven load and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

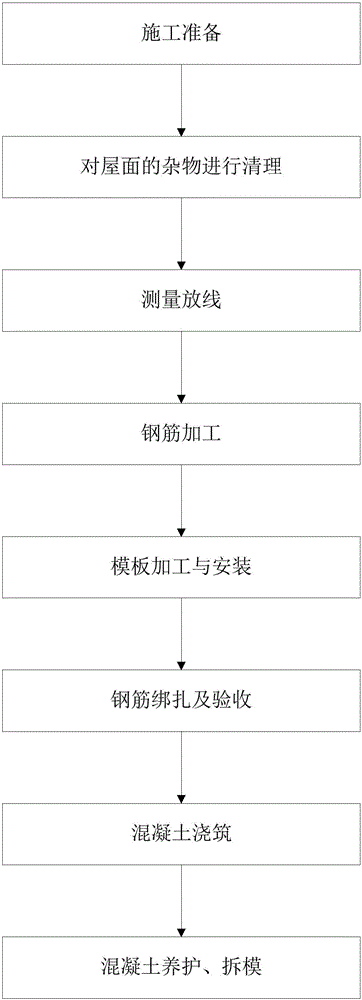

[0097] The roof photovoltaic strip foundation construction method includes the following steps:

[0098] (1), construction preparation

[0099] (11) Familiar with the construction drawings, confirm that the concrete foundation elevation, center line, length, embedded parts and steel bar size spacing meet the design requirements;

[0100] (12) Compile the construction plan and carry out the construction process design;

[0101] (13) Calculate and measure the amount of steel bars, concrete, and formwork according to the construction drawings and site conditions;

[0102] (2) Clean up the sundries on the roof

[0103] (3), measuring and setting out

[0104] Before construction, use a total station to measure and set out according to the construction drawings, and mark the relevant axis positions with red paint, and conduct re-measurement according to the axes of the drawings and construction requirements.

[0105] (4), steel bar processing

[0106] (41), steel bar raw materi...

specific Embodiment 3

[0140] The roof photovoltaic strip foundation construction method includes the following steps:

[0141] (1), construction preparation

[0142] (11) Familiar with the construction drawings, confirm that the concrete foundation elevation, center line, length, embedded parts and steel bar size spacing meet the design requirements;

[0143] (12) Compile the construction plan and carry out the construction process design;

[0144] (13) Calculate and measure the amount of steel bars, concrete, and formwork according to the construction drawings and site conditions;

[0145](2) Clean up the sundries on the roof

[0146] (3), measuring and setting out

[0147] Before construction, use a total station to measure and set out according to the construction drawings, and mark the relevant axis positions with red paint, and conduct re-measurement according to the axes of the drawings and construction requirements.

[0148] (4), steel bar processing

[0149] (41), steel bar raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com