Ballastless track structure with lateral dynamic load balance on sleeper side

A ballastless track and dynamic load technology, applied in the field of ballastless track structure, can solve the problems of insufficient construction space of the ditch, intrusion of the track pipe into the ditch, inconvenience and hidden dangers of construction and maintenance, and achieve convenient drainage and pipeline passing track, reducing the width of the ballast bed, and saving track construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

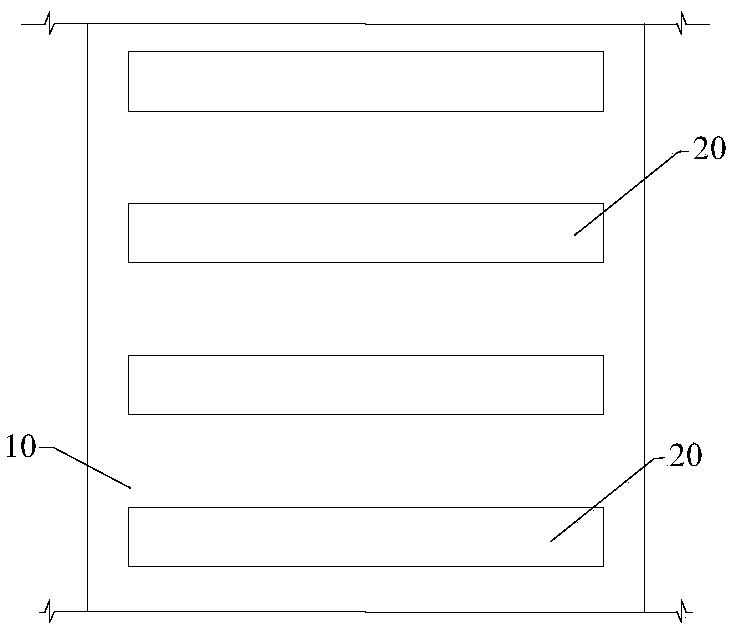

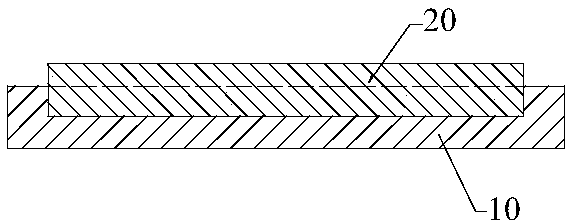

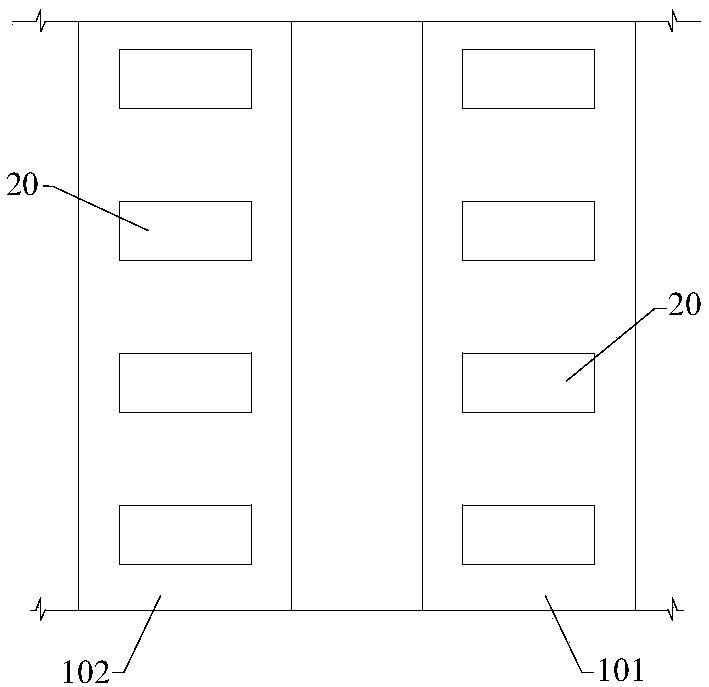

[0027] refer to figure 1 and figure 2 The existing ballastless track structure includes a ballast bed 10 and sleepers 20 arranged at intervals along the line extension direction. The sleeper 20 is a prefabricated reinforced concrete member, and its lower part is embedded in the ballast bed 10 when the cast-in-place track bed 10 is formed, and forms a closed pit around it. The cross-section of the sleeper 20 along its longitudinal direction is a constant cross-section type, and the joint surface between the two ends and the pit of the ballast bed 10 forms a bearing surface to bear the transverse dynamic load. Its disadvantage is that the width of the ballast bed 10 is relatively large, which affects the setting of drains and pipelines, and it is not possible to increase the space and reduce the cost of the project by reducing the lateral width of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com