An automatic carton packing machine

A cartoning machine and carton technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problem that the laminated finished carton is not completely packed into the packaging box, the finished carton and the packaging box are easily damaged, and the packaging process takes a long time. problem, to achieve the effect of accurate and efficient packing process, reduce packing cost, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention will be described below with reference to examples. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

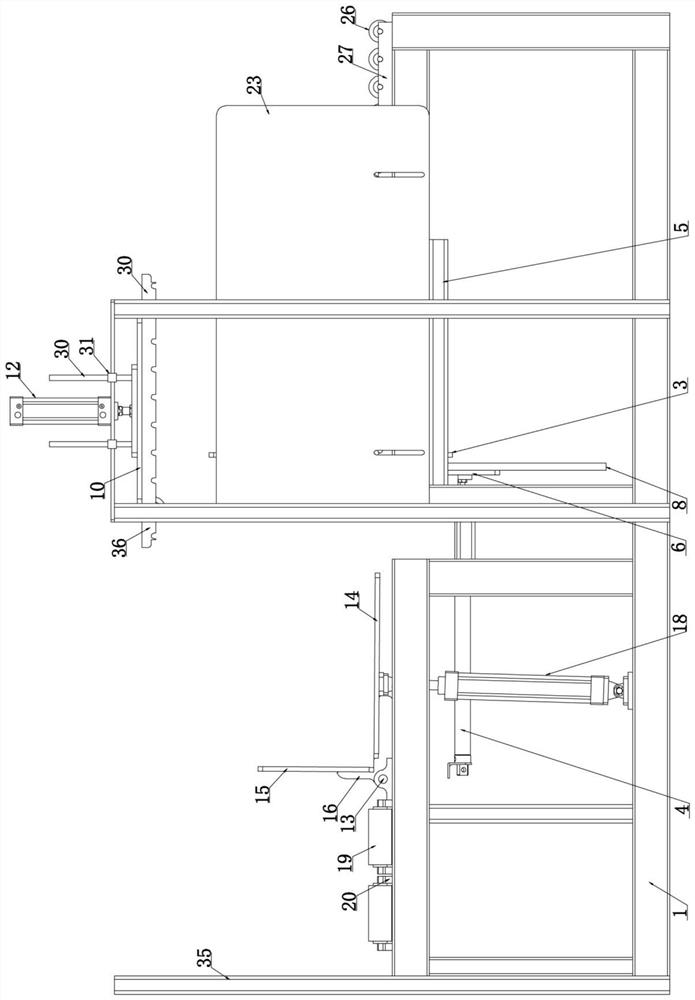

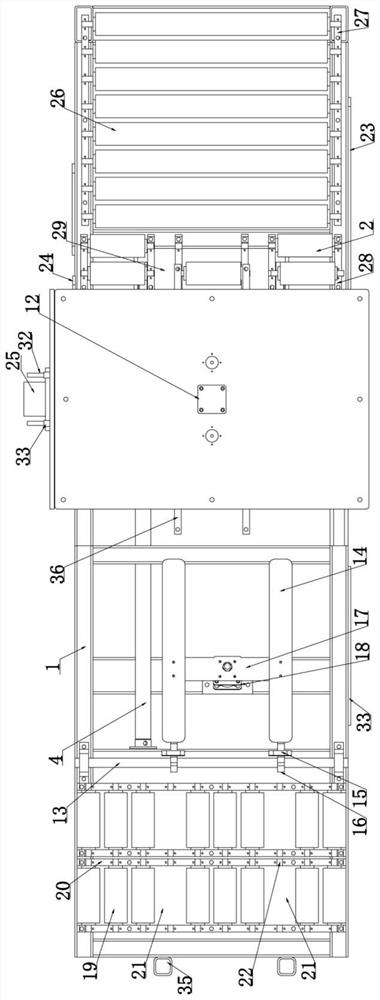

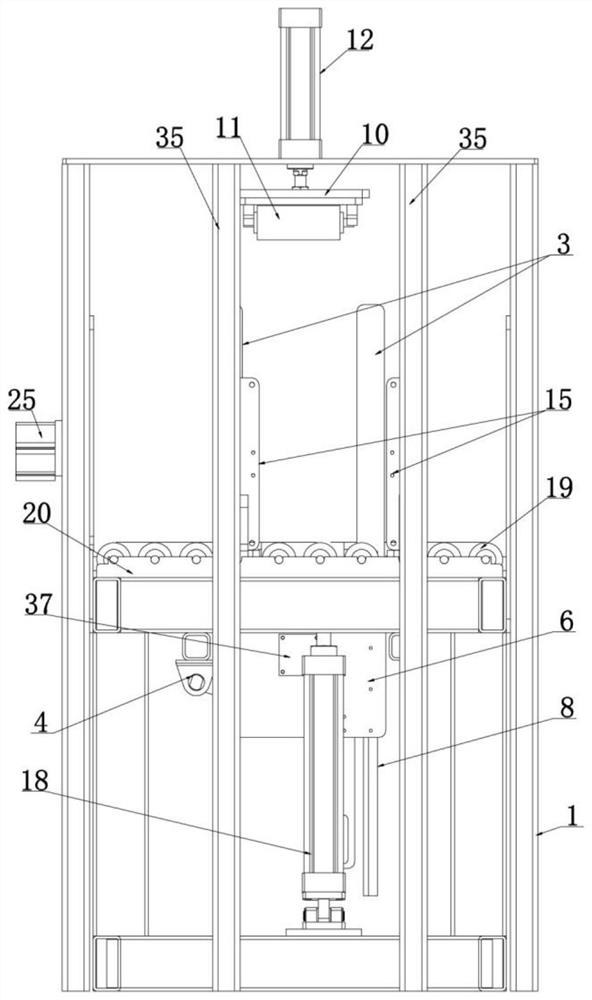

[0038] like Figure 1-Figure 7 As shown, an automatic carton packing machine includes a frame 1 and a feeding mechanism, a pushing mechanism, a pressing mechanism, a packaging box positioning mechanism and a discharging mechanism arranged on the frame. The feeding mechanism It includes at least two rows of feeding rollers 2, the feeding rollers 2 are arranged on the frame through the feeding rack 28, and the two ends of the feeding roller are connected with the feeding frame through bearings;

[0039] The pushing mechanism includes a push rod 3 and a push rod driving mechanism. The push rod driving mechanism includes a push rod moving mechanism for controlling the forward and backward movements of the push rod and a push rod moving mechanism for control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com