Radial fastening device of high-strength hot rolled strip steel coil

A hot-rolled strip steel and fastening device technology, which is applied in the direction of binding materials and binding machine parts, etc., can solve the problems of limited production capacity of strip production, increased manual replacement of binding strips, and slow transportation of steel coils. , to achieve the effect of improving packaging efficiency and security, avoiding excessive manual participation, and ensuring overall consistency and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

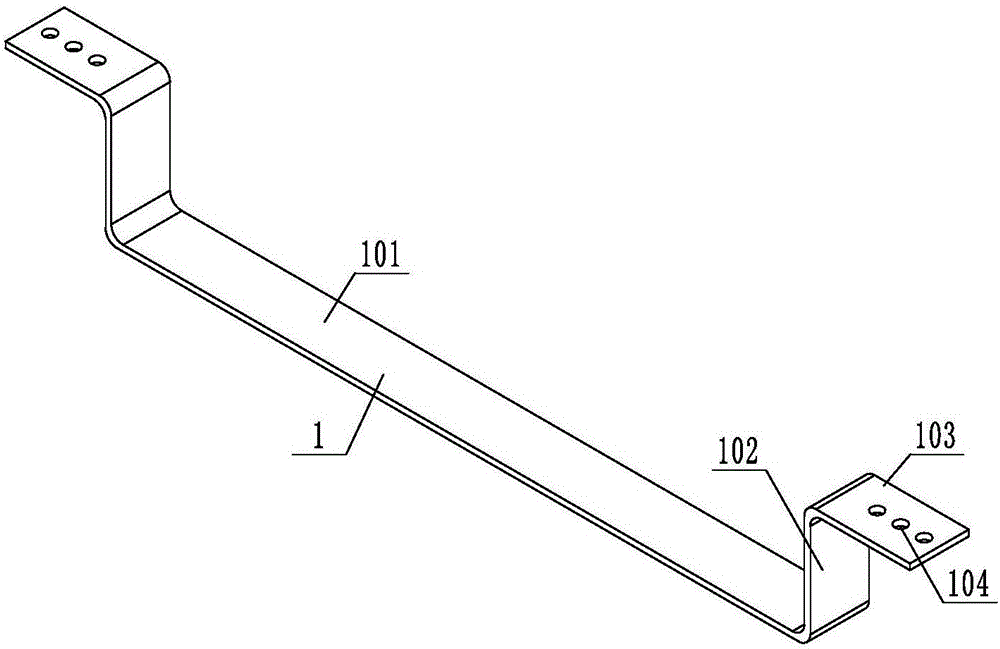

[0021] Such as Figure 1 to Figure 4 as shown,

[0022] A radial fastening device for high-strength hot-rolled strip steel coils includes a radial fastening strip 1, such as figure 2 As shown, the radial fastening strip includes a large horizontal plate 101, a middle connecting plate 102, a small horizontal plate 103 and a bolt hole 104, and the large horizontal plate 101, the middle connecting plate 102, and the small horizontal plate 103 are a hot-rolled strip It is processed by cold-bending strip steel, and both sides of the large horizontal plate are symmetrically bent to have a middle connecting plate and a small horizontal plate.

[0023] In an optimized solution, the angle between the large horizontal plate 101 and the middle connecting plate 102 is 90 degrees, and the angle between the middle connecting plate 102 and the small horizontal plate 103 is less than 90 degrees.

[0024] The material of the large horizontal plate 101, the middle connecting plate 102 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com