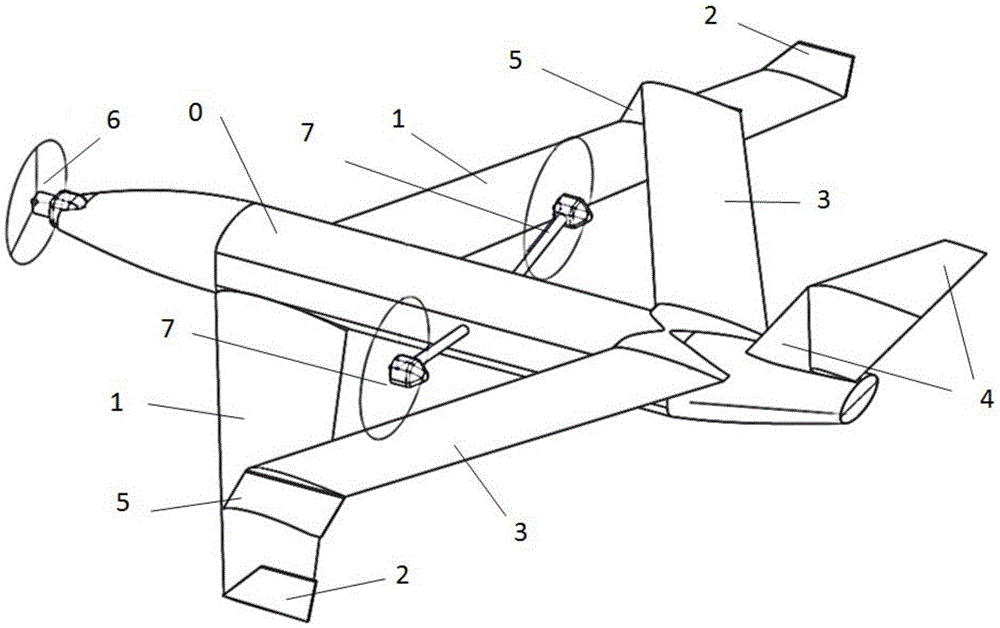

Overall design of tilt-rotor aircraft

An aircraft and front wing technology, applied in the directions of wings, aircraft parts, aircraft control, etc., can solve the problems of difficult flight control technology and control system design, large coupling dynamic load between rotor and wing, serious impact on aircraft stability, etc. The effect of improving gliding ability, reducing induced drag, and reducing operational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following content describes in detail the specific embodiment of the present invention in conjunction with the accompanying drawings:

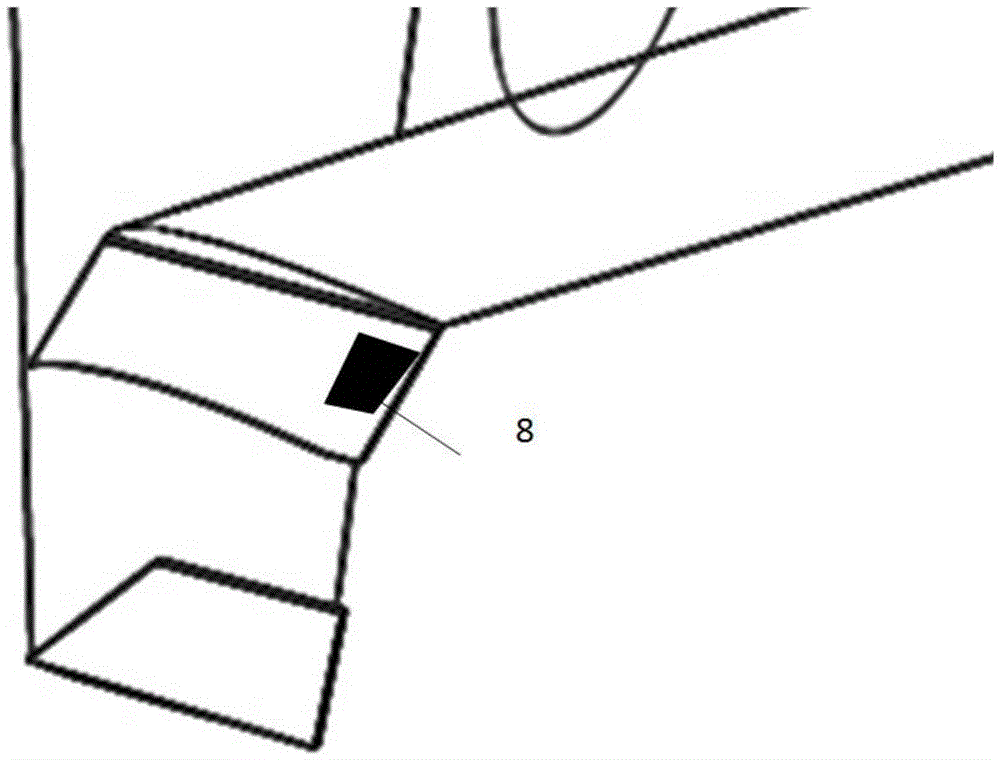

[0039] see figure 1 , figure 2 , the aircraft includes a fuselage 0, a front wing 1 and a T-tail 4, wherein the end of the front wing 1 is equipped with a winglet 2, and the connecting plate 5 is equipped with a damping plate 8, which assists the linkage of the T-tail 4 when turning The forward sweep of the rear wing 3 contains anhedral, and the angle is 1-2 degrees. Flaps (not shown in the figure) are equipped, and the connection position with the front wing 1 is 70% of the position away from the fuselage on the front wing 1. , the rear wing 3 is connected to the front wing 1 through a connecting plate 5 .

[0040] The front wing 1 is swept up and reversed, with flaps (not shown in the figure) and adjustable slats (not shown in the figure).

[0041] The front wing 1 and the rear wing 3 are combined to form a structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com