Edge folding mechanism

A base and cylinder technology, applied in the field of hemming mechanism, can solve problems such as low production efficiency, uneven edges, and high labor intensity of operators, and achieve the effect of improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

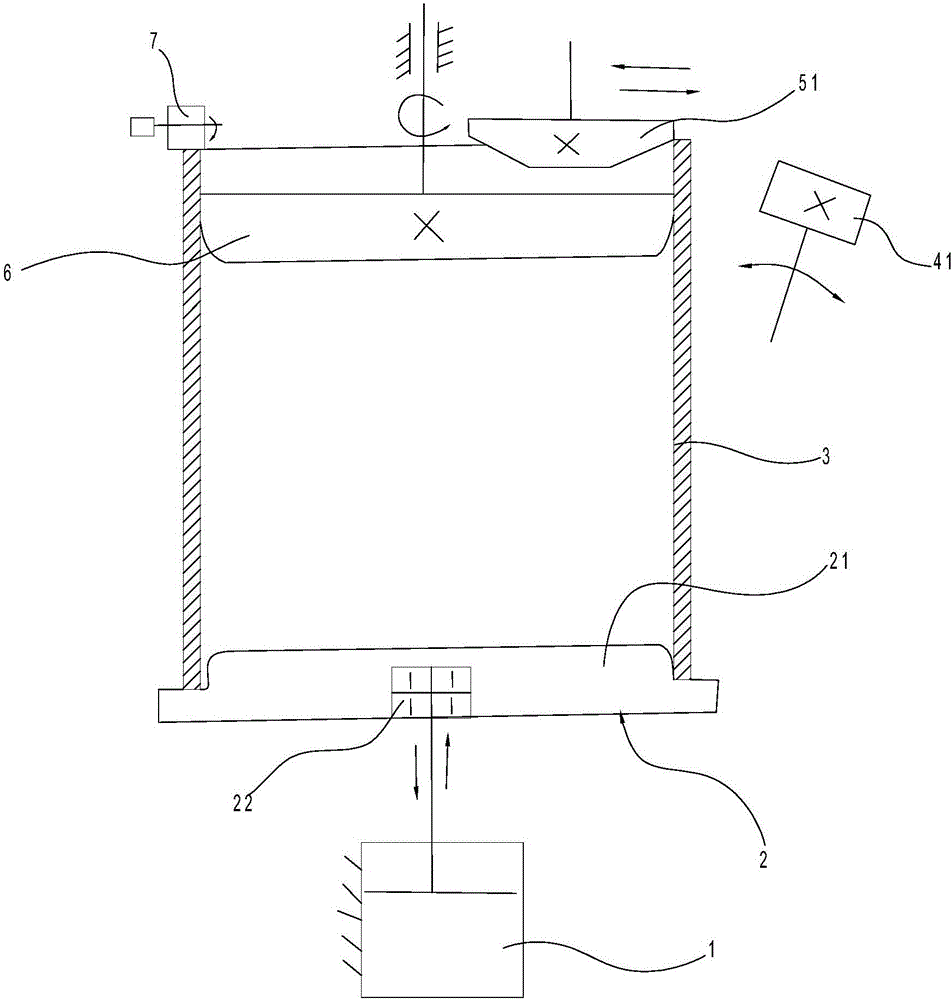

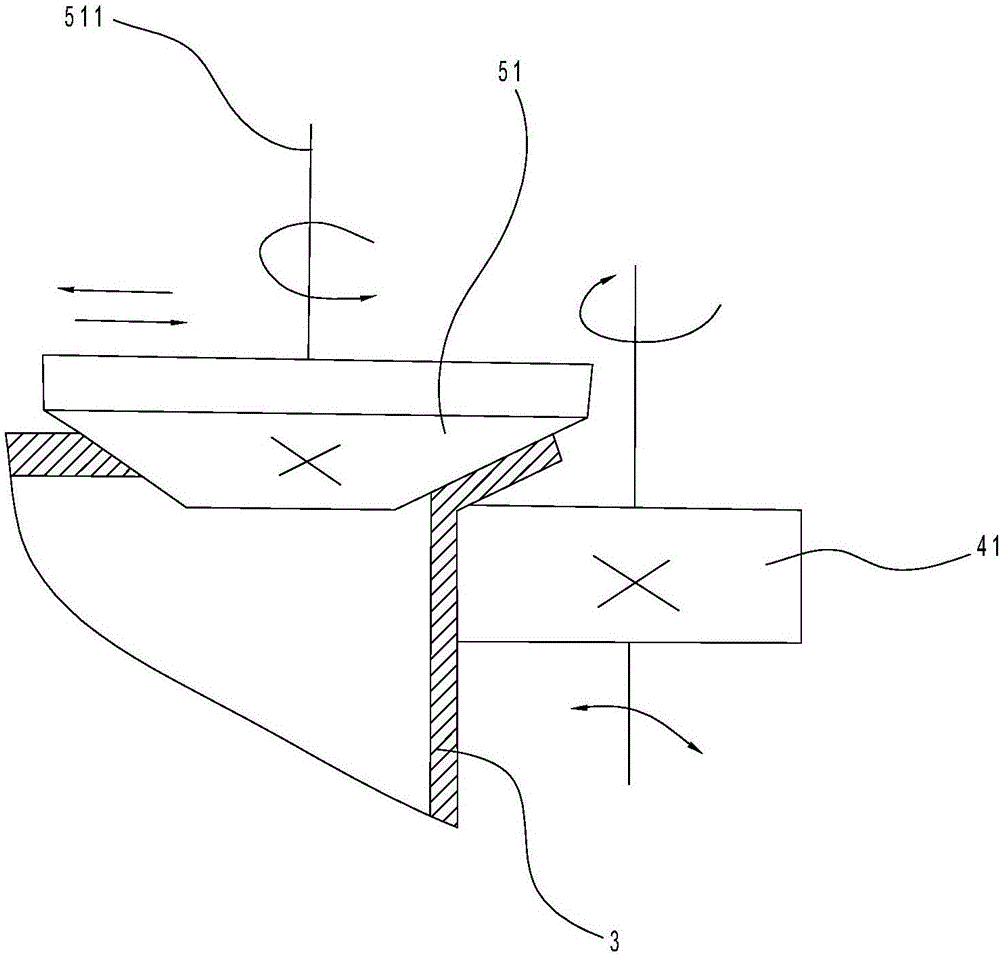

[0017] Such as Figures 1 to 4 As shown, the hemming mechanism of the cylinder in this implementation includes a base 10, a cylinder 1, a tray 2, a turntable 6, a pressure roller 7, an outer pressure roller 41, an inner pressure roller 51, a first cam 52, a second cam 45. First roller 531, second roller 422, driven rod 53, sliding sleeve 56, guide rod 55, first spring 54, second spring 46, bearing 42, drive motor 44, rotating shaft 43 and bearing 22.

[0018] Wherein, a cylinder 1 is fixed on the base 10, and the end of the piston rod of the cylinder 1 is rotated through a bearing 22 to be provided with a tray 2 for placing the cylinder body 3 that needs to be hemmed. The raised portion 21 inserted into the inner wall of the cylinder body 3, by setting the raised portion 21, the fixed support of the cylinder body 3 on the tray 2 is improved, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com