Automatic folding and rubber band bundling all-in-one machine for plastic bag

A plastic bag and all-in-one machine technology, which is applied to the parts of strapping machinery, transportation and packaging, paper product packaging, etc., can solve problems such as complex structure, irregular handles of plastic bags, and affecting work speed and efficiency. , to achieve the effect of uniform width specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

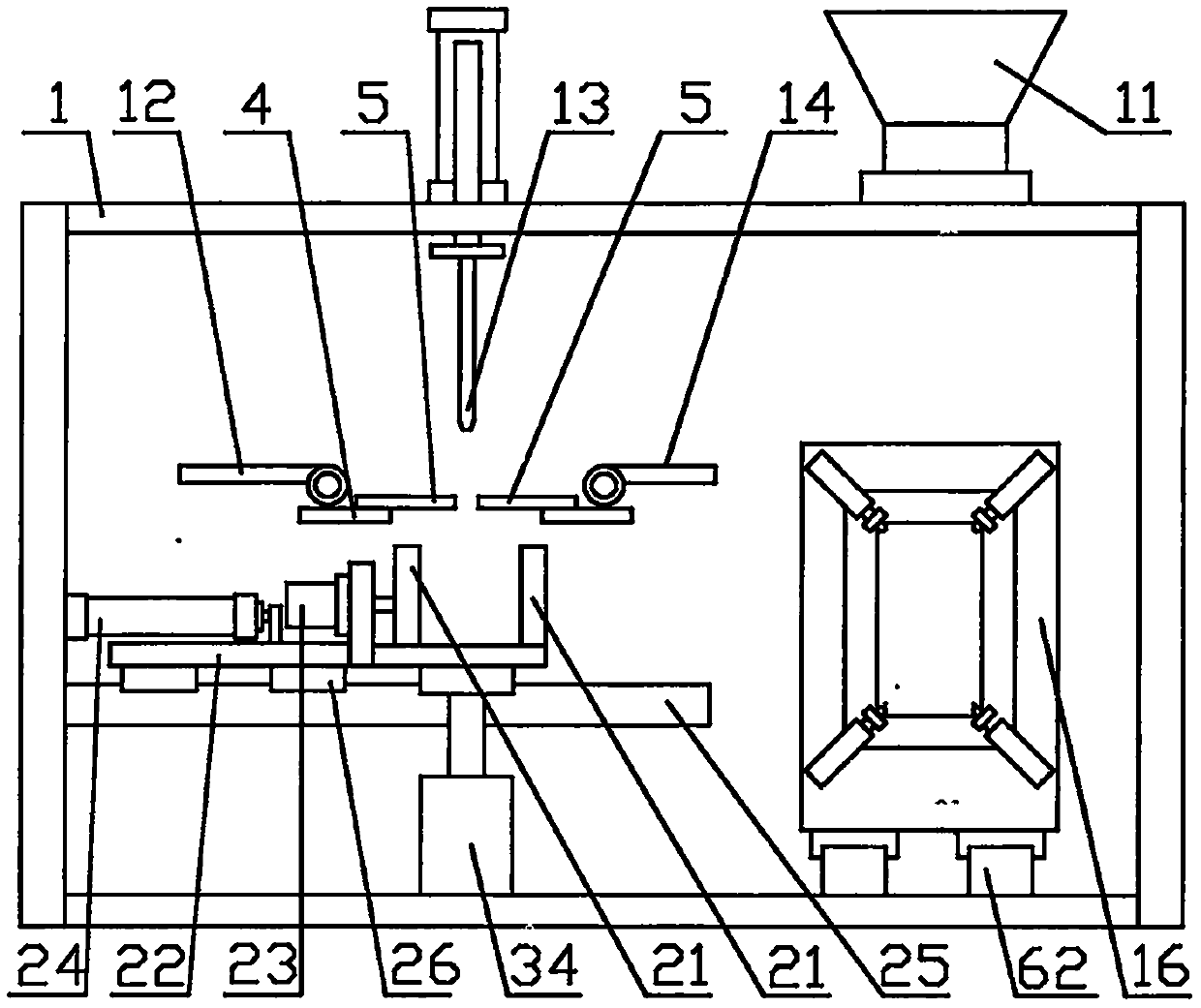

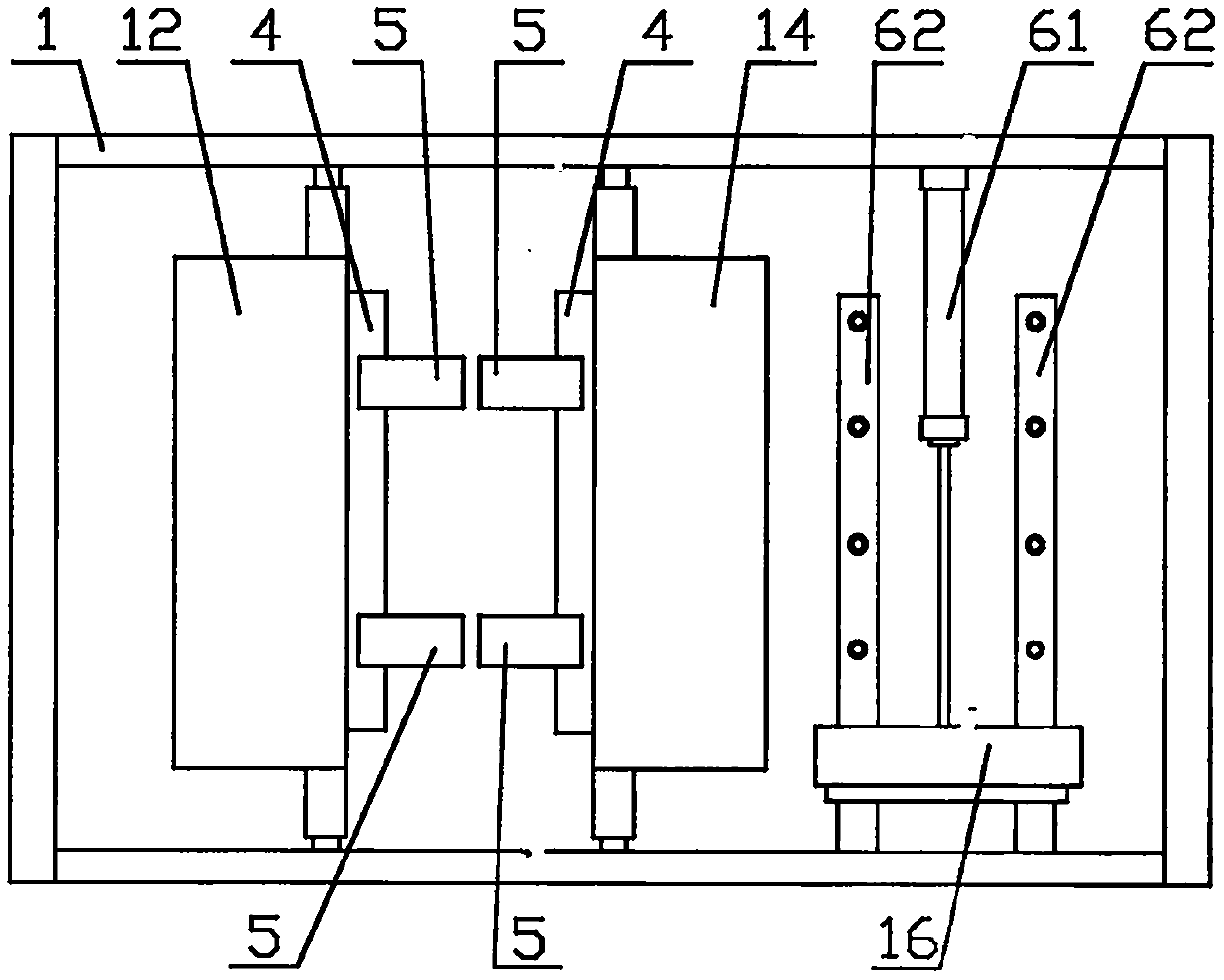

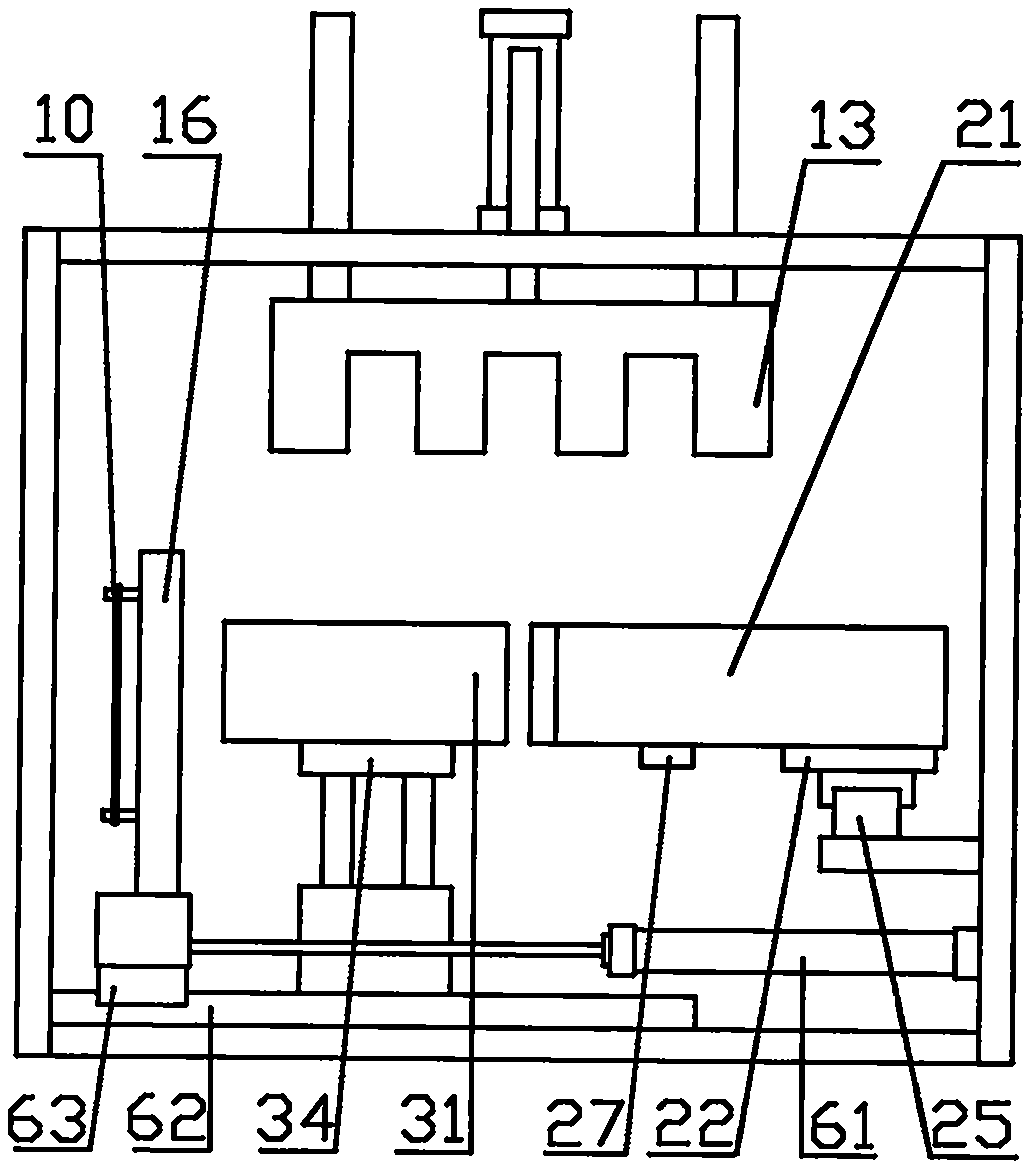

[0055] Embodiment one, such as Figure 1 to Figure 3 As shown: the handle folding device 2 is mainly composed of a front corner folding mechanism, a trapezoidal front folding plate mechanism, a bag pressing hook mechanism, a pressing plate mechanism, etc.; the tail folding device 14 is mainly composed of a rear folding plate and a swing cylinder , a telescopic compression rod mechanism, etc.; Please refer to reference documents 1, 2, 3, and 4 for the specific implementation of the handle folding device 12, insert plate device 13 and tail folding device 14; please refer to reference document 5 or comparison for the vibrating plate device 15 and rubber band stretching device 16. The specific implementation of file 6 will not be repeated here.

[0056] Such as figure 1 , figure 2 As shown: install the board device 13 on the top of the frame 1, install the handle folding device 12 and the tail folding device 14 on the front and rear sides corresponding to the board device 13, ...

Embodiment 2

[0058] Embodiment 2, the main difference between embodiment 2 and embodiment 1 is that the handle folding device of embodiment 2 is a plastic bag head folding device composed of an adjustable supporting plate mechanism, a U-shaped pushing and folding plate mechanism, etc. The device can be specifically implemented with reference to the comparison document whose publication number is CN109264120A or CN208361926U; as Figure 15 , Figure 16 As shown, the splint retraction device is a pneumatic mechanical clamp 30 . The two splints of the pneumatic manipulator 30 can swing to the middle to form a U-shaped space so that the plastic bag 8 is inserted by the inserting plate 13 to form a double fold, and then the two splints of the pneumatic manipulator 30 are clamped to the middle again to make the plastic bag 8 by V Clamped and shaped into a U-shape, then the two splints swing about 90 degrees to both sides, so that the splints at the back are lower than the downside of the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com