Folding mechanism of non-woven bag

A non-woven bag, folding mechanism technology, applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc., can solve the problems of complex structure, reduce storage space and other problems, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

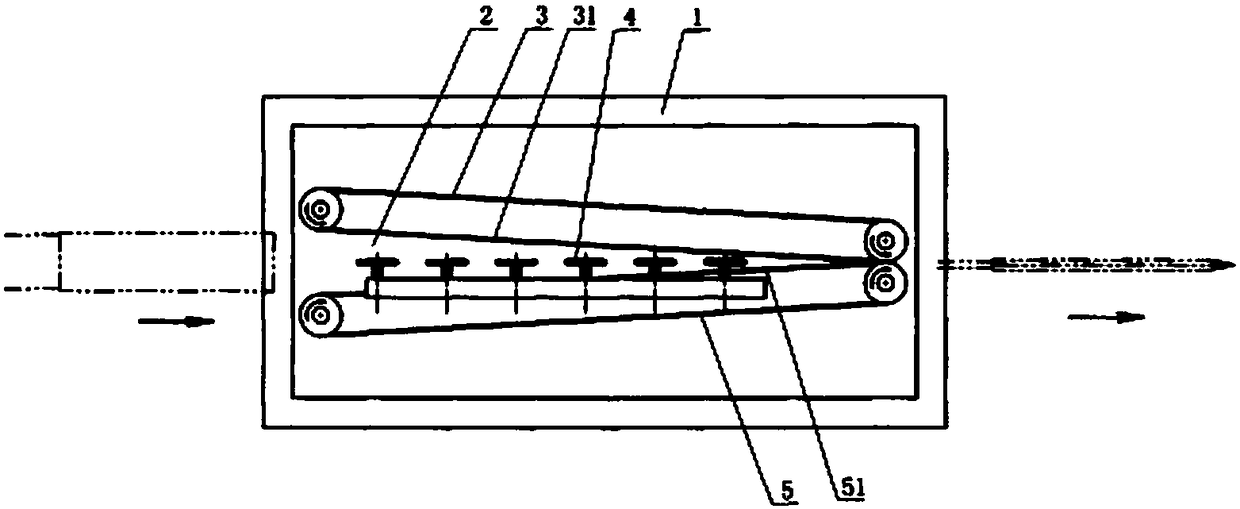

[0010] like figure 1 , 2 As shown, the non-woven bag folding mechanism of the present invention includes a folding passage 2 located in the middle of the frame 1, the folding passage 2 is surrounded by an upper conveying flat belt 3 and a lower conveying flat belt 5, and the upper and lower conveying flat belts have the same Linear speed, the transmission direction of the upper and lower conveying flat belts is the same as the length direction of the folding channel, the front end of the folding channel 2 is the inlet of the non-woven bag, and the rear end is the outlet of the non-woven bag, and the upper wall of the folding channel 2 corresponds to the upper conveying flat belt The lower belt surface 31 of 3, the lower wall of the folding channel 2 corresponds to the upper belt surface 51 of the lower conveying flat belt 5, and the lower belt surface 31 of the upper conveying flat belt and the upper belt surface 51 of the lower conveying flat belt are arranged in a V shape T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com