Vibration knocking device and mining dump vehicle

A technology of vibrating rods and impacting balls, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, and vehicles used for freight transportation. Simple, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

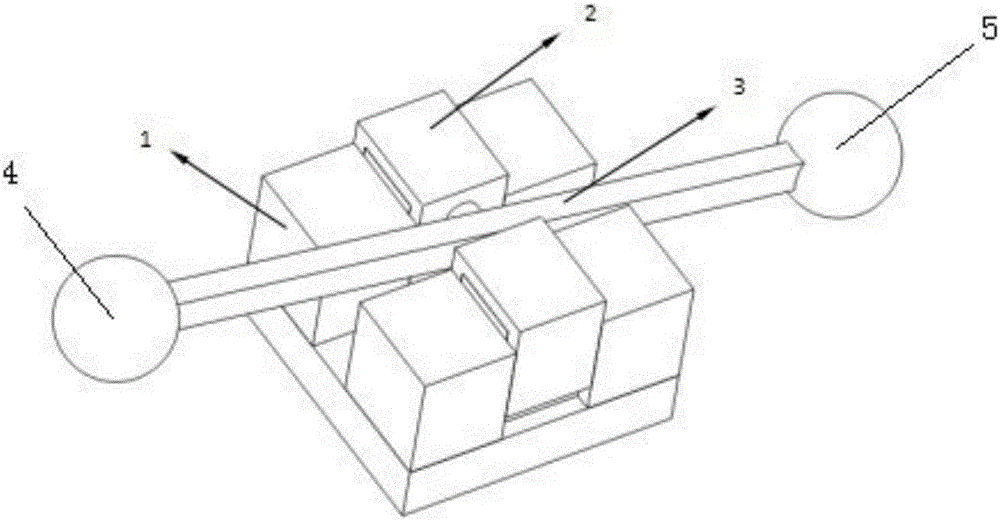

[0012] Such as figure 1 As shown, a vibration percussion device includes a base 1, a vibrating rod 3, a support 2 arranged on the base 1, and A hitting ball 4 and B hitting ball 5 installed at both ends of the vibrating rod, and the A hitting ball 4 and the B impact ball 5 are all made of metal, and the vibrating rod 3 is installed on the support 2 and can swing freely around the support; the A electromagnet 6 is arranged below the A impact ball 4, and the B impact ball 5 A B electromagnet 7 is arranged below, and the impact ball is reciprocated by supplying power to the A electromagnet 6 and the B electromagnet 7 intermittently.

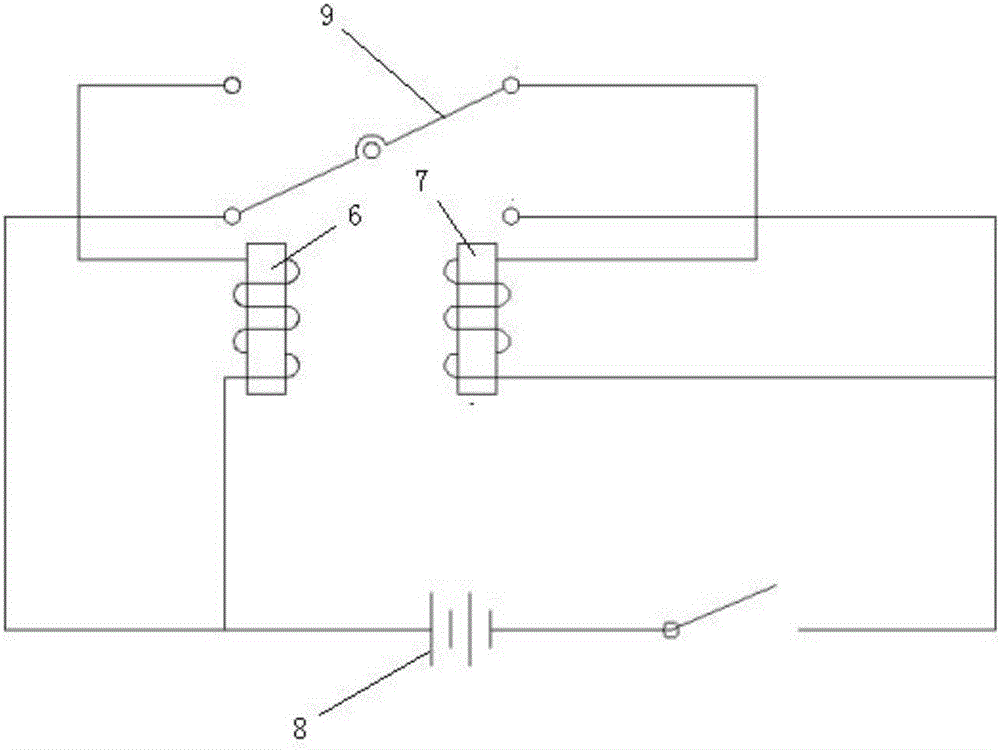

[0013] A electromagnet 6 and B electromagnet 7 are controlled by a control circuit, such as figure 2 As shown, the control circuit includes a power supply 8 and a double-head switch 9. The positive pole of the power supply 8 is connected to one end of the coil of the A electromagnet 6 and one end of the first contact of the double-head switch 9; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com