Damping double-rotation stirrer

A stirrer, double-rotation technology, applied to mixers with rotating stirring devices, mixer accessories, chemical instruments and methods, etc., can solve the problems of slow stirring speed, large vibration, cleaning waste, etc., and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

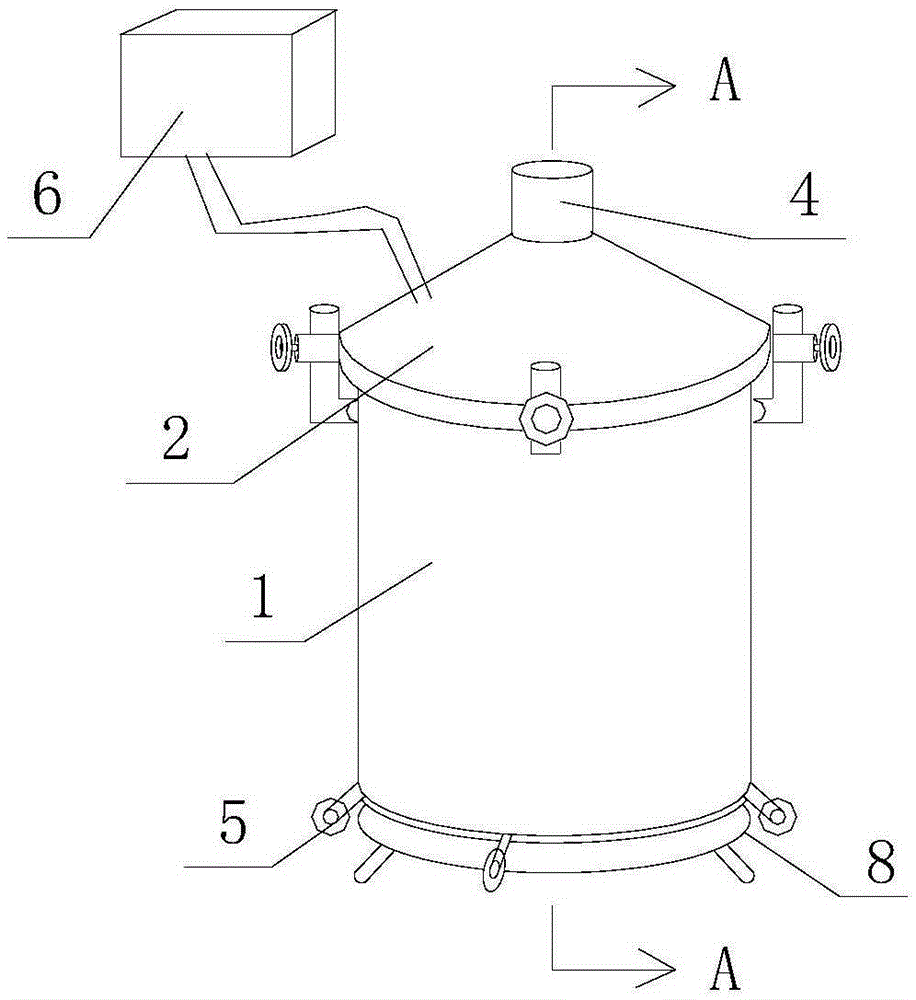

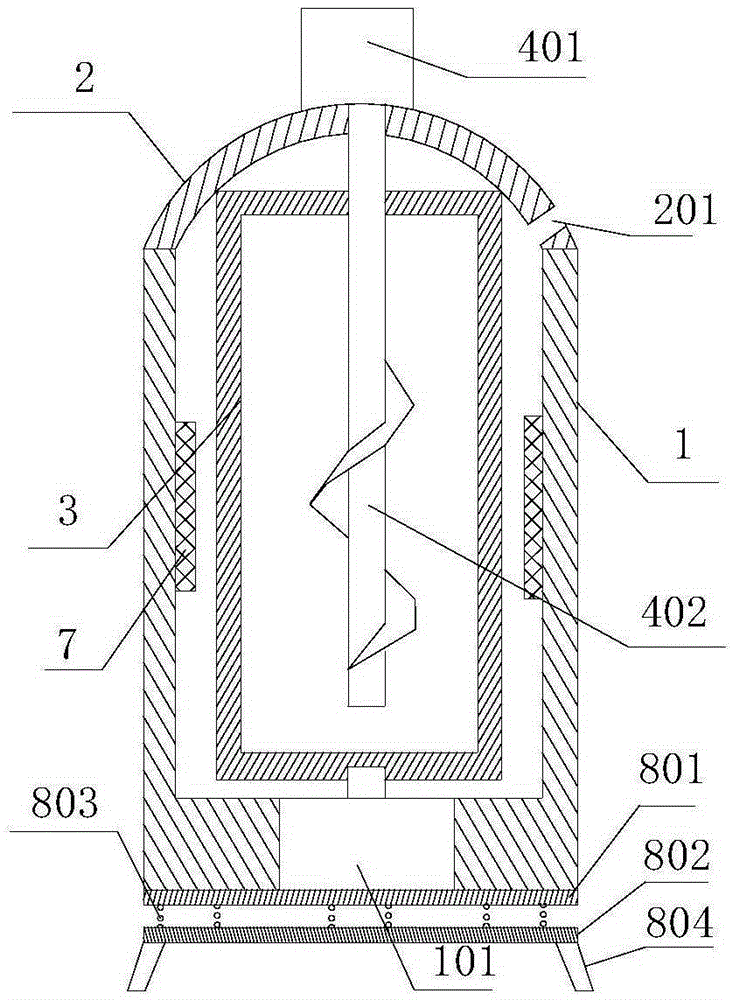

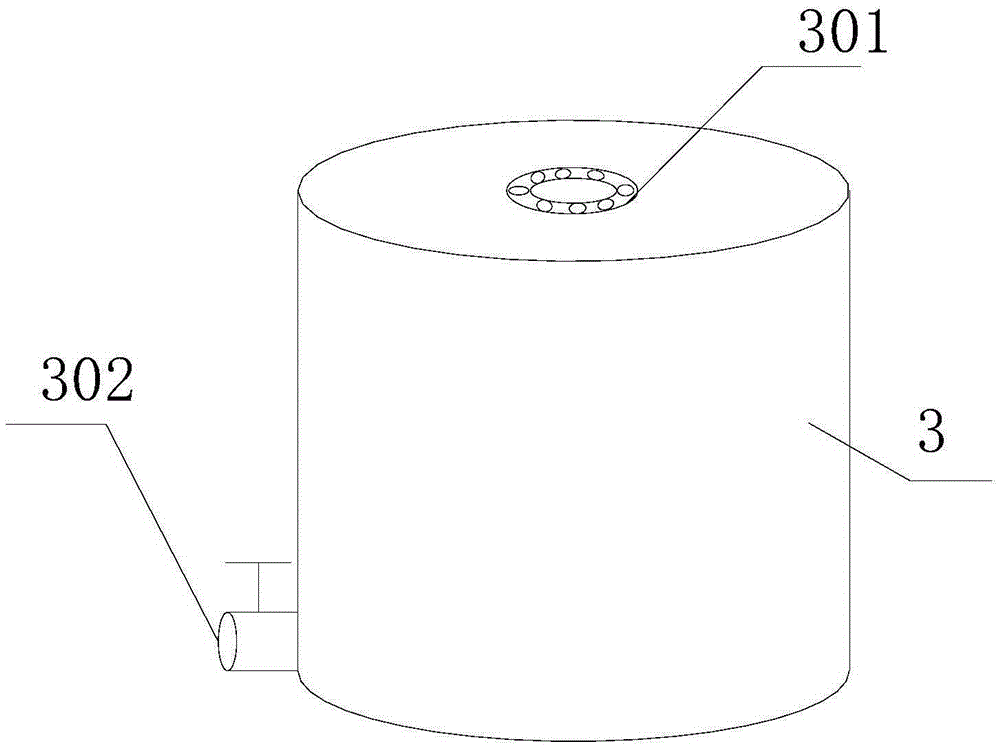

[0024] Such as Figure 1 to Figure 3 As shown, the shock-absorbing double-rotating agitator includes a tank body 1, a tank cover 2 is arranged on the upper end of the tank body 1, and an inner tank 3 is arranged inside it, and a rotating motor 101 is arranged on the inner bottom of the tank body 1. The bottom end of the tank 3 is connected to the machine shaft of the rotating motor 101, and the upper end of the inner tank 3 is rotatably connected with the tank cover 2. The tank cover 2 is provided with an agitator 4, and the agitator 4 includes a motor 401 and a stirring rod 402. The stirring rod 402 is driven by the motor 401 to rotate, and it passes through the tank cover 2 and extends into the inner tank 3. The inner tank 3 is provided with a bearing 301 at the connection with the stirring rod 402, so that the inner tank 3 and the stirring rod 402 have no At the same time as the seam connection, without affecting the rotation of the stirring rod 402, the side wall of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com