Preparation method for fried and crispy green bean fish bones

A production method and green bean technology, applied in the field of food processing, can solve the problems that the nutrition of green beans cannot be fully absorbed by the human body, and no green beans and fish bone products and reports have been seen, so as to achieve good economic benefits and avoid unbalanced nutritional intake. , the effect of rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

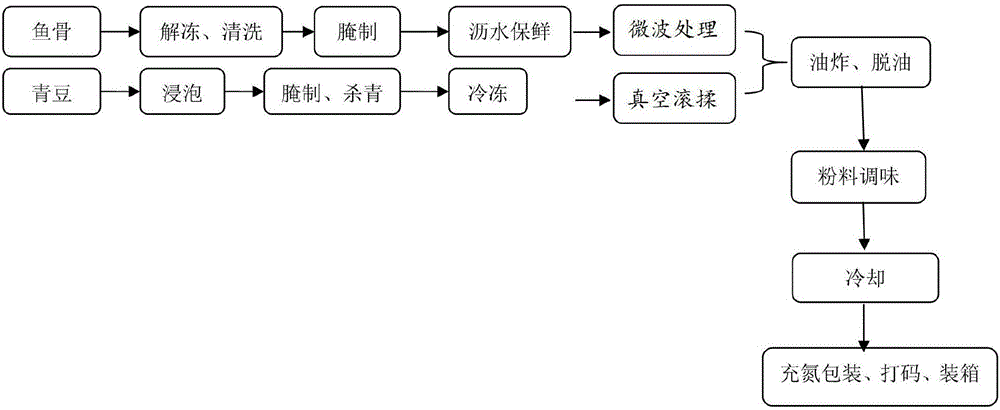

[0044] Such as figure 1 As shown, a method for making crispy green bean crispy fish bones, the method steps are as follows:

[0045] (1) Raw material pretreatment

[0046] Fish bones: The raw materials are fresh or frozen fish spines with no pollution. After cleaning and cutting the fish bones, marinate them with marinade for 55 minutes. Store in the fresh-keeping store for 4 hours, and then take it out for use; the purpose of fresh-keeping is to increase the processing amount of fish spines, and the second is to keep the nutrients of fish spines from being lost;

[0047] The first marinade is composed of the following components in parts by weight: 80 parts of water, 2 parts of salt, 1.2 parts of white sugar, 2.5 parts of cooking wine, and 1.5 parts of ginger;

[0048] Green beans: Select green beans with uniform size, no pests, and no mildew, soak them in drinking water, soak for 10 hours in summer and autumn, and soak for 18 hours in spring and winter, then put them in th...

Embodiment 2

[0062] Such as figure 1 As shown, a method for making crispy green bean crispy fish bones, the method steps are as follows:

[0063] (1) Raw material pretreatment

[0064] Fish bones: The raw material is fresh or frozen fish spines with meat that are not polluted. After cleaning and cutting the fish bones, marinate them with marinade for 50 minutes, then drain them and put them in the water at a temperature of 6°C and a humidity of 78%. Store in the fresh-keeping store for 4 hours, and then take it out for use; the purpose of fresh-keeping is to increase the processing amount of fish spines, and the second is to keep the nutrients of fish spines from being lost;

[0065] The first marinade is composed of the following components in parts by weight: 80 parts of water, 1.5 parts of salt, 1 part of white sugar, 2 parts of cooking wine, and 1.2 parts of ginger;

[0066] Green beans: Select green beans with uniform size, no pests, and no mildew, soak them in drinking water, soak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com