Mint flavor chocolate and production method thereof

A chocolate and lotus-flavored technology, applied in cocoa, food science, application, etc., can solve the problems of monotonous taste and greasy feeling of pure chocolate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

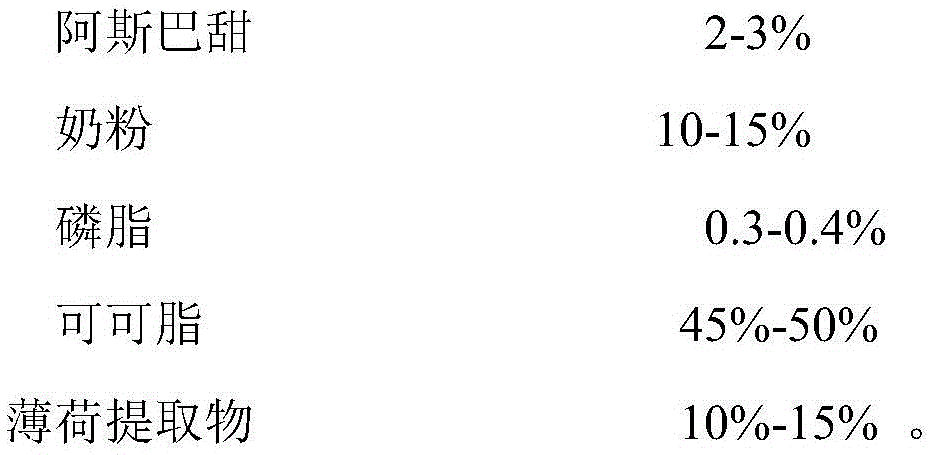

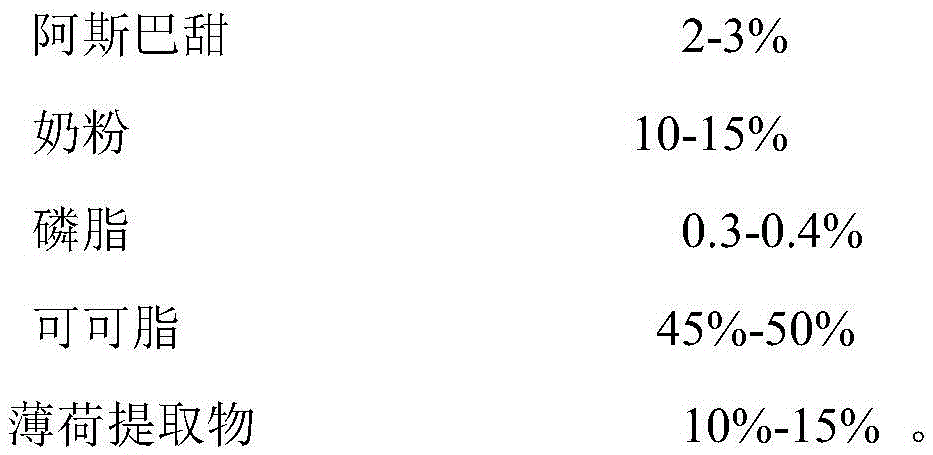

[0012] The raw materials are aspartame 2%, milk powder 10%, phospholipid 0.3%, cocoa butter 50%, and peppermint extract 15%. First melt the cocoa butter at a temperature of 50°C. Then pour the hazelnut kernels together for fine grinding. After fine grinding, the average fineness is 30 microns. During the fine grinding process, the temperature is always kept at 43-45°C. During the fine grinding process, the current does not exceed 30 amperes, and the fine grinding time is 15 hours. Then adjust the temperature, the temperature is always controlled at 43-45°C, and the temperature adjustment time is 10 hours. The raw materials are poured into the pouring machine for casting, and then the mold is released and packaged.

Embodiment 2

[0014] The raw materials are aspartame 3%, milk powder 15%, phospholipid 0.4%, cocoa butter 45%, and peppermint extract 10%. First melt the cocoa butter at a temperature of 50°C. Then pour the hazelnut kernels together for fine grinding. After fine grinding, the average fineness is 30 microns. During the fine grinding process, the temperature is always kept at 43-45°C. During the fine grinding process, the current does not exceed 30 amperes, and the fine grinding time is 15 hours. Then adjust the temperature, the temperature is always controlled at 43-45°C, and the temperature adjustment time is 10 hours. The raw materials are poured into the pouring machine for casting, and then the mold is released and packaged.

Embodiment 3

[0016] The raw materials are aspartame 2%, milk powder 13%, phospholipid 0.3%, cocoa butter 48%, and peppermint extract 3%. First melt the cocoa butter at a temperature of 50°C. Then pour the hazelnut kernels together for fine grinding. After fine grinding, the average fineness is 30 microns. During the fine grinding process, the temperature is always kept at 43-45°C. During the fine grinding process, the current does not exceed 30 amperes, and the fine grinding time is 15 hours. Then adjust the temperature, the temperature is always controlled at 43-45°C, and the temperature adjustment time is 10 hours. The raw materials are poured into the pouring machine for casting, and then the mold is released and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com