Transparent plastic sheet

A technology of transparent plastic sheets and sheets, which can be used in electronic equipment, other household appliances, synthetic resin layered products, etc., and can solve the problems of high deformation, low light resistance and surface performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] PC resin (LC Chemicals) with a glass transition temperature of 147°C and PMMA resin with a glass transition temperature of 129°C (terpolymer PMMA resin, 15% to 70% styrene, 25% to 80% formazan) were prepared. methacrylate and 5% to 50% maleic anhydride). In addition, the barrel diameter of the extruder for forming the support layer was 150 mm, the screw L / D=35, the barrel temperature was 270° C., and the barrel diameter of the extruder for forming the surface layer was 45 mm, and the screw L / D=35. D = 35, the cylinder temperature is 245°C. Subsequently, the PC resin was introduced into the extruder for forming the support layer, and the PMMA resin was fed into the extruder for forming the surface layer, and the two resins were simultaneously melt-extruded.

[0050] The internal temperature of a die pad was set at 270° C. and 245° C., and the stacked and integrated resin in the die was guided through three polishing rolls which were mirror-polished and arranged in a hor...

example 2 and 3

[0052] The transparent plastic sheets of Examples 2 and 3 were produced in the same manner as Example 1, except that a terpolymer PMMA resin with a glass transition temperature of 120° C. and a terpolymeric resin with a glass transition temperature of 130° C. were used, respectively. Material PMMA resin.

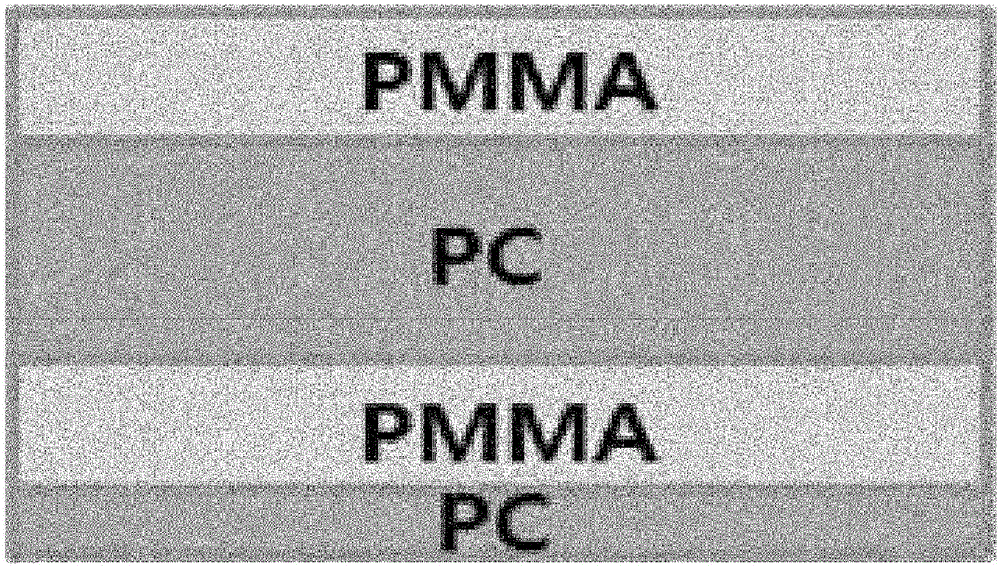

example 4

[0054] Co-extrusion was carried out in the same manner as in Example 1, except that as an extruder for forming the support layer, a first extruder (barrel diameter of 150 mm, screw L / D=35, barrel temperature of 270 ℃), the second extruder (barrel diameter is 45mm, screw L / D=35, barrel temperature 245°C) and the third extruder (barrel diameter is 45mm, screw L / D=35, barrel temperature 245°C ℃), and the PC resin, the terpolymer PMMA resin and the PC resin were sequentially fed into the extruder to form a supporting layer. The extrusion speeds of the first extruder, the second extruder, the third extruder, and the sub-extruder were set at a weight ratio of 70:15:15, and thus a transparent plastic sheet (thickness 1 mm) was Manufactured as: the surface layer is 0.15mm thick, and the thickness of the first support layer (PC, bottom layer), the second support layer (PMMA, middle layer) and the third support layer (PC, boundary layer) are 0.1mm, 0.15mm, respectively and 0.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com