High-voltage switch cabinet

A high-voltage switchgear and switchgear technology, applied to switchgear components, substation/switch layout details, vertical pulling and isolated switchgear, etc., can solve problems such as incomplete interlocking, low protection level, and unstable structure , to achieve the effect of stable and reliable up and down movement, enhanced electrical insulation performance, and reasonable structure of the jacking mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

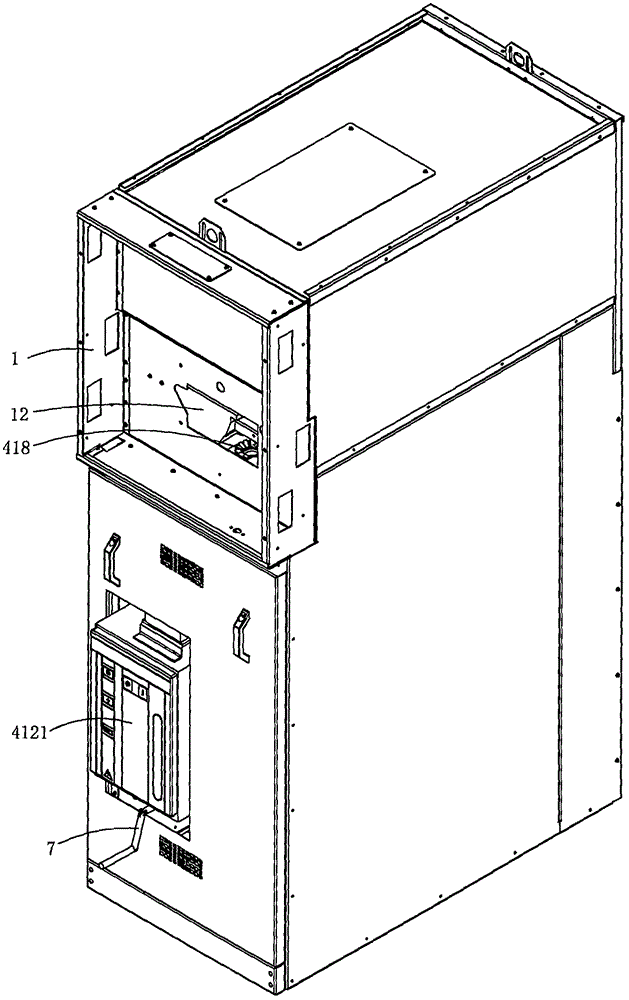

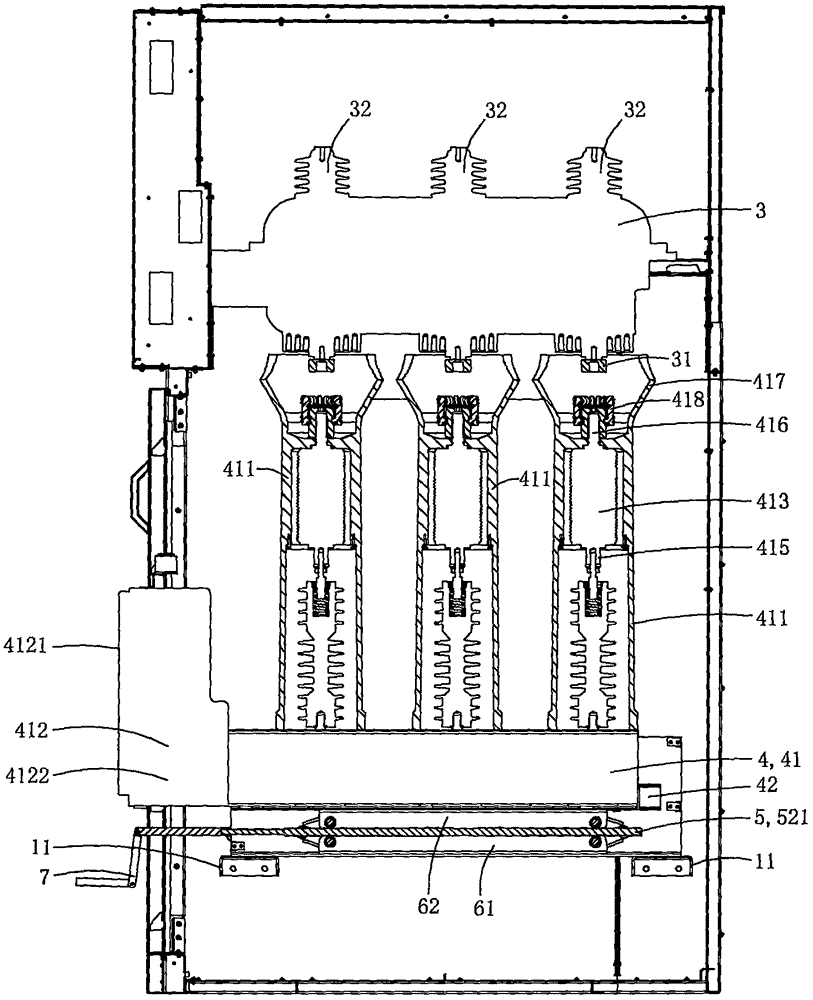

[0030] Figure 1 to Figure 9 One specific embodiment of the invention is shown.

[0031] This embodiment is a kind of high voltage switchgear, see Figure 1 to Figure 9 As shown, it includes a cabinet body 1, a jack-up vacuum circuit breaker 2 and a power access device 3.

[0032] The jack-up vacuum circuit breaker 2 includes a side-mounted vacuum circuit breaker 4 and a jacking device 5 for driving the side-mounted vacuum circuit breaker 4 to reciprocate along the vertical direction;

[0033] The side-mounted vacuum circuit breaker 4 includes a vacuum circuit breaker body 41 and a base 42. The vacuum circuit breaker body includes a three-phase pole 411 and a side-mounted operating mechanism 412; each phase pole is provided with a vacuum set along the vertical direction. The switching tube 413 and the side-out terminal 414; the moving contact 415 of each vacuum switching tube is on the bottom, and the static contact 416 is on the top; each side-out terminal 414 is electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com