Temperature compensation packaging device for fiber laser

A fiber laser and temperature compensation technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problem of inability to eliminate the frequency drift of fiber gratings, and achieve the effect of compensating for temperature rise expansion and improving frequency stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with examples and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

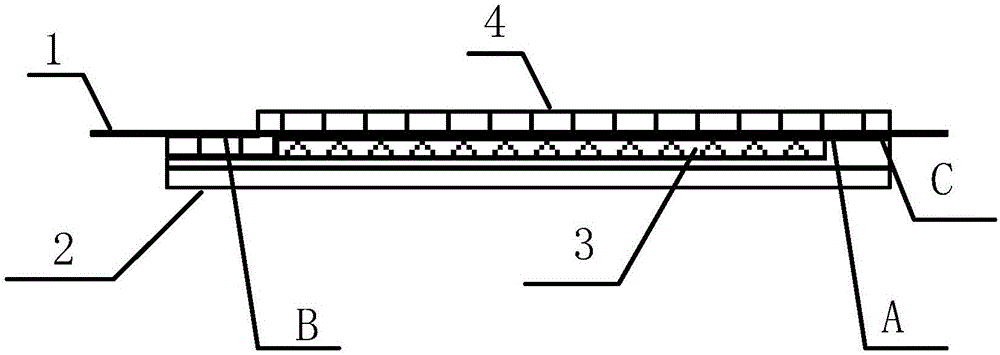

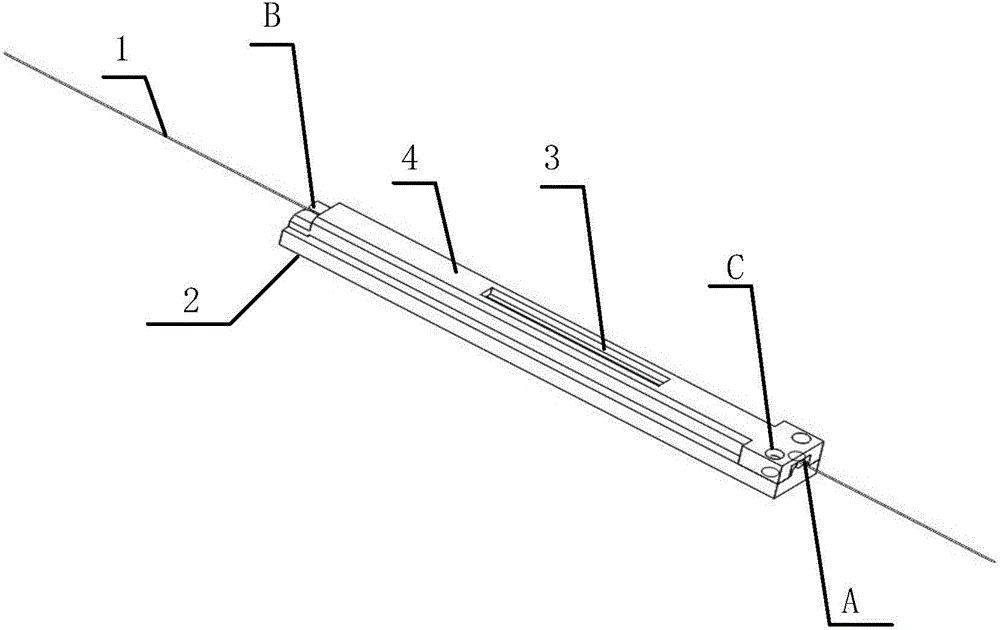

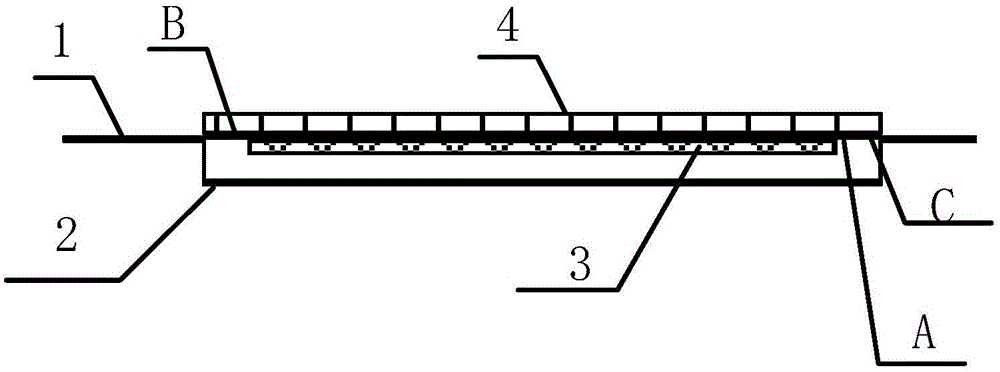

[0022] see first figure 1 with figure 2 , figure 1 It is a structural block diagram of the fiber laser temperature compensation packaging device of the present invention, figure 2 It is a perspective view of the fiber laser temperature compensation packaging device of the present invention. It can be seen from the figure that the fiber laser temperature compensation packaging device of the present invention comprises a fiber laser 1 , a metal base 2 , a V-shaped groove 3 and a metal cover 4 . The fiber laser 1 is composed of a Bragg grating photoetched on an optical fiber at one end, the metal base 2 is made of a slender aluminum material, and the V-shaped groove 3 is formed on the metal base by machining 2, the fiber laser 1 can be embedded in the V-shaped groove 3 and main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com