Multi-side pressing type intermediate quick energy-saving conductive connector

A technology of conductive joints and conductive heads, which is applied in the direction of conductive connections, circuits, connections, etc., can solve problems such as power loss, locking screws that are easy to fall out, and long time for connecting wires, etc., and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

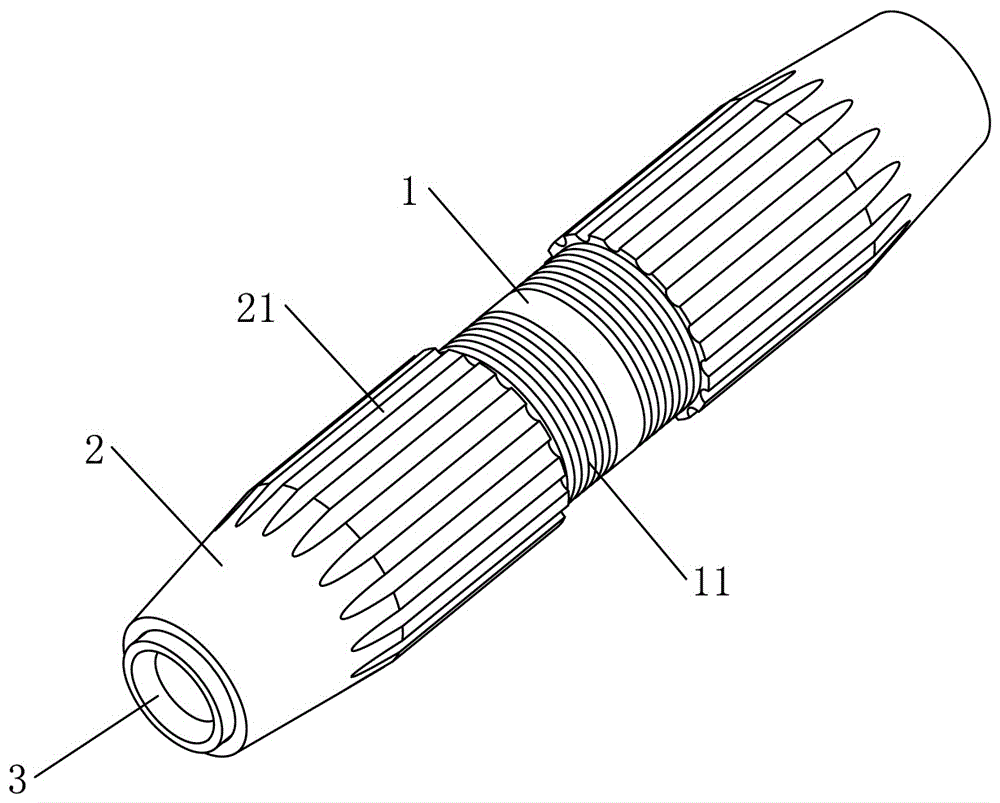

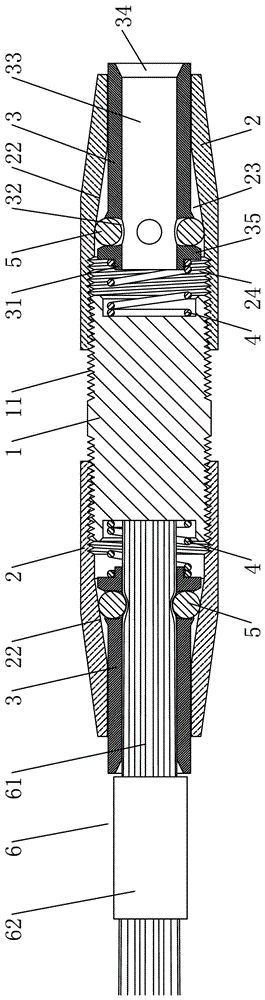

[0028] Embodiment one, see figure 1 and figure 2 As shown, a multi-faceted top-pressing type intermediate fast energy-saving conductive joint includes an intermediate conductive head 1, and the intermediate conductive head 1 is provided with two externally threaded ends 11, and the externally threaded ends 11 are provided with a conductive wire locking device, which is electrically conductive The wire locking device includes an outer lock nut 2, and the outer lock nut 2 is provided with a sleeve hole 23 passing through its two ends, and one end of the sleeve hole 23 is provided with an internal thread 24, and the internal thread 24 is threadedly connected with the external thread end 11. The conductive wire locking device also includes an inner threading tighter sleeve 3 and a plurality of crimping tops 5; the inner threading tighter sleeve 3 is provided with a threading hole 33, and one end of the threading hole 33 leads to the outside of the inner threading tighter sleeve 3...

Embodiment 2

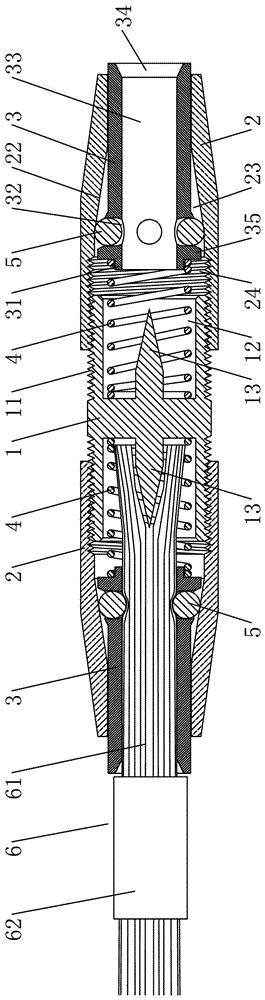

[0036] Embodiment two, see figure 1 and image 3As shown, a multi-faceted top-pressing type intermediate fast energy-saving conductive joint includes an intermediate conductive head 1, and the intermediate conductive head 1 is provided with two externally threaded ends 11, and the externally threaded ends 11 are provided with a conductive wire locking device, which is electrically conductive The wire locking device includes an outer lock nut 2, and the outer lock nut 2 is provided with a sleeve hole 23 passing through its two ends, and one end of the sleeve hole 23 is provided with an internal thread 24, and the internal thread 24 is threadedly connected with the external thread end 11. The conductive wire locking device also includes an inner threading tighter sleeve 3 and a plurality of crimping tops 5; the inner threading tighter sleeve 3 is provided with a threading hole 33, and one end of the threading hole 33 leads to the outside of the inner threading tighter sleeve 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com