Shaping device

A shaping device and technology of shaping plates, which are applied in the direction of battery assembly, sustainable manufacturing/processing, electrochemical generators, etc., can solve the problems of slow shaping speed, speed up shaping, avoid tension or even breakage, Effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

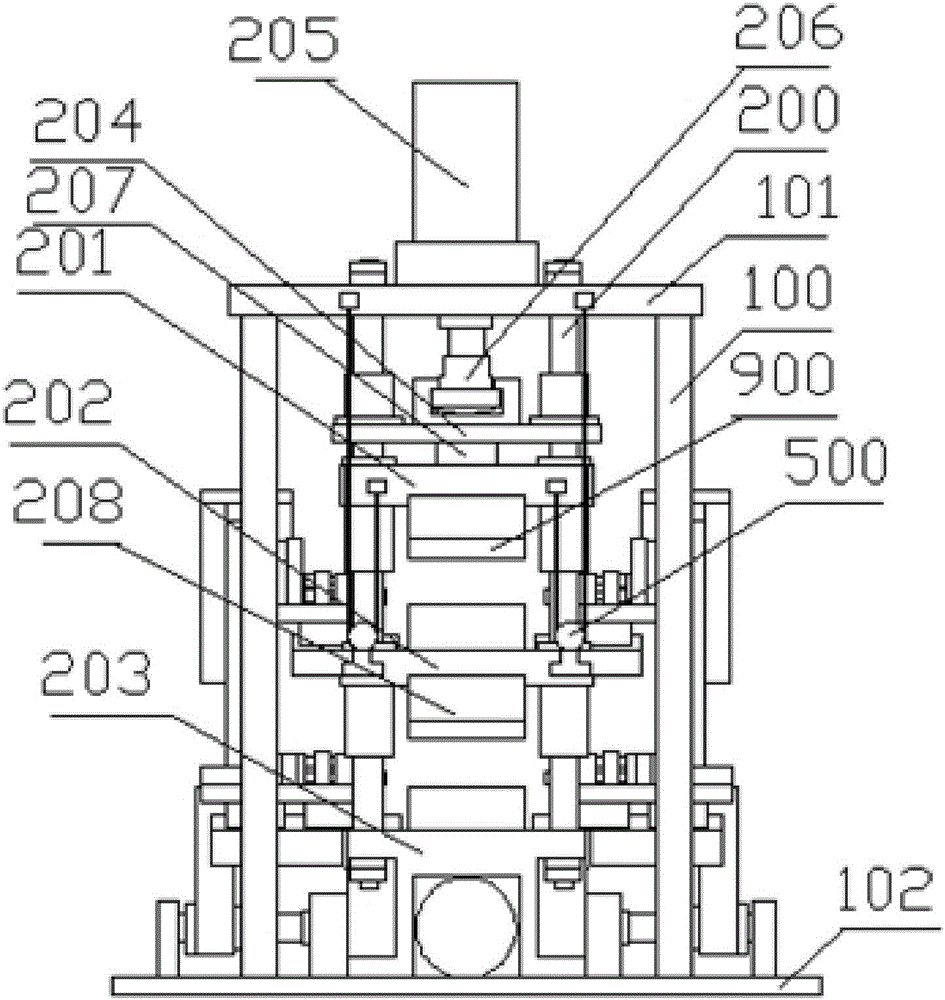

[0032] Such as figure 1 , image 3 , Figure 4 As shown, the shaping device of the present invention mainly includes a support frame, a pressing mechanism, a side pressing mechanism and a pulley mechanism.

[0033] The support frame mainly includes a support column 100 , an upper support plate 101 and a lower support plate 102 . There are four supporting columns 100, respectively corresponding to the four corners of the upper supporting plate 101 and the lower supporting plate 102. The lower part of the supporting column 100 is fixedly connected to the lower supporting plate 102, and the upper part is fixedly connected to the upper supporting plate 101 to provide support for the shaping device. .

[0034] The pressing mechanism mainly includes guide column 200 , first pressing plate 201 , second pressing plate 202 , supporting plate 203 , guiding plate 204 , electric cylinder 205 , floating joint 206 , pressure sensor 207 , and vertical heating and pressing plate 208 . The...

Embodiment 2

[0046] Such as figure 2 As shown, the shaping device of the present invention also includes a support frame, a pressing mechanism, a side pressing mechanism and a pulley mechanism. The difference between the shaping device in Embodiment 2 and the shaping device in Embodiment 1 mainly lies in the side pressing mechanism. , the following will mainly introduce the lateral pressure mechanism in Embodiment 2. The side pressure mechanism in Example 2 uses a reducer to realize power splitting, and then combines some connection mechanisms to realize the shaping of the sides of the battery cells in the two shaping spaces through a motor, which simplifies the device and reduces the cost of the device. Effect.

[0047] Such as Figure 6 As shown, the lateral pressure mechanism in Embodiment 2 mainly includes a lateral pressure motor 600, a reducer 601, a lead screw 602, a nut 603, a first connecting plate 604, a first bearing plate 605, a vertical plate 606, and a second connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com