Feature-basedthree-dimensional machiningtechnology layout system and method

A processing method and process technology, applied in the field of feature-based three-dimensional machining process arrangement system, can solve the problem of not being able to see the complete information of the process and its associated steps at the same time, not providing a good process arrangement method, and not conducive to the editing operation of craftsmen To achieve the effect of improving the quality and efficiency of process planning, efficient machining process design, and convenient and quick process arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below, examples of said embodiments are shown in the accompanying drawings, and the embodiments described below by referring to the accompanying drawings are exemplary, are only used to explain the present invention, and cannot be construed as explanations for the present invention limit.

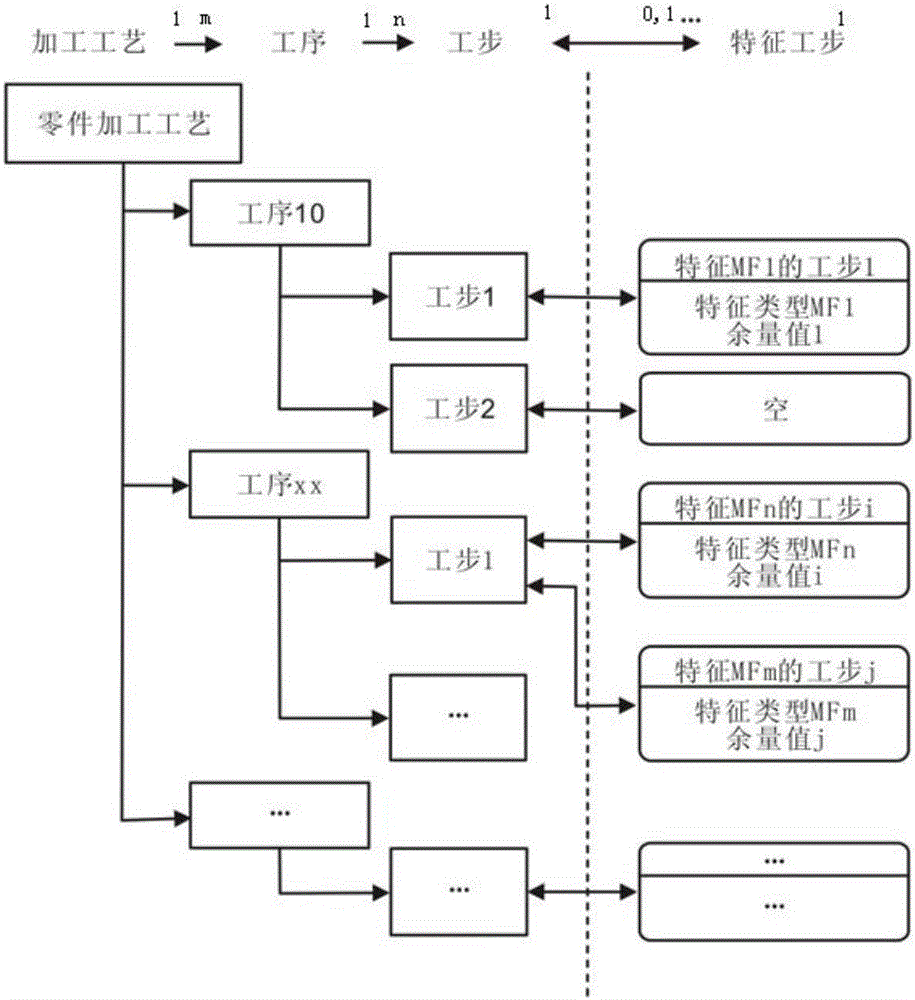

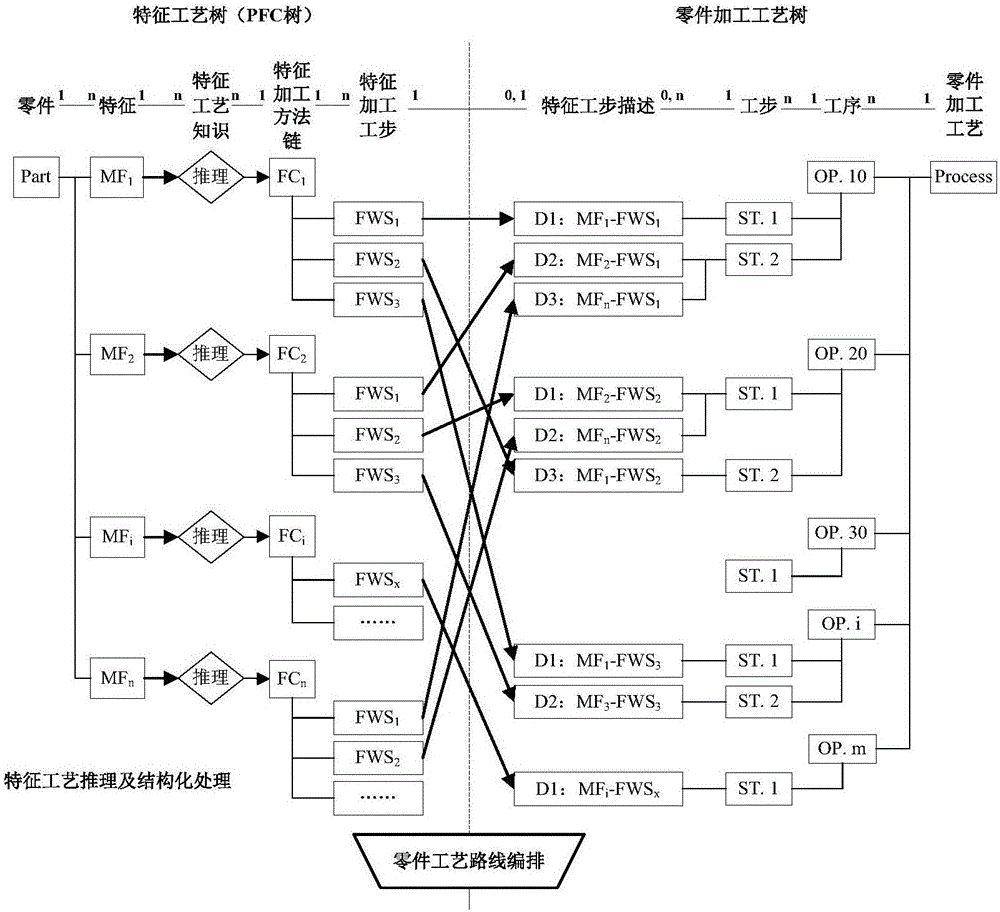

[0030] The general technical idea of the present invention is: after the 3D process design system obtains the process information of the parts and the full 3D model file, through the automatic identification of the manufacturing features in the 3D model, the knowledge-based parametric design idea is adopted to intelligently generate the manufacturing features. The processing method, and then through human-computer interaction, generate a part-oriented machining process. A feature-based three-dimensional machining process layout system and method proposed by the present invention directly recognizes manufacturing features ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com