TSV Reliability Analysis Method

An analysis method, the technology of through-silicon vias, applied in the field of microelectronics, can solve problems such as no consideration of stress, large storage resources, and long simulation time of electrothermal three-field coupling, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

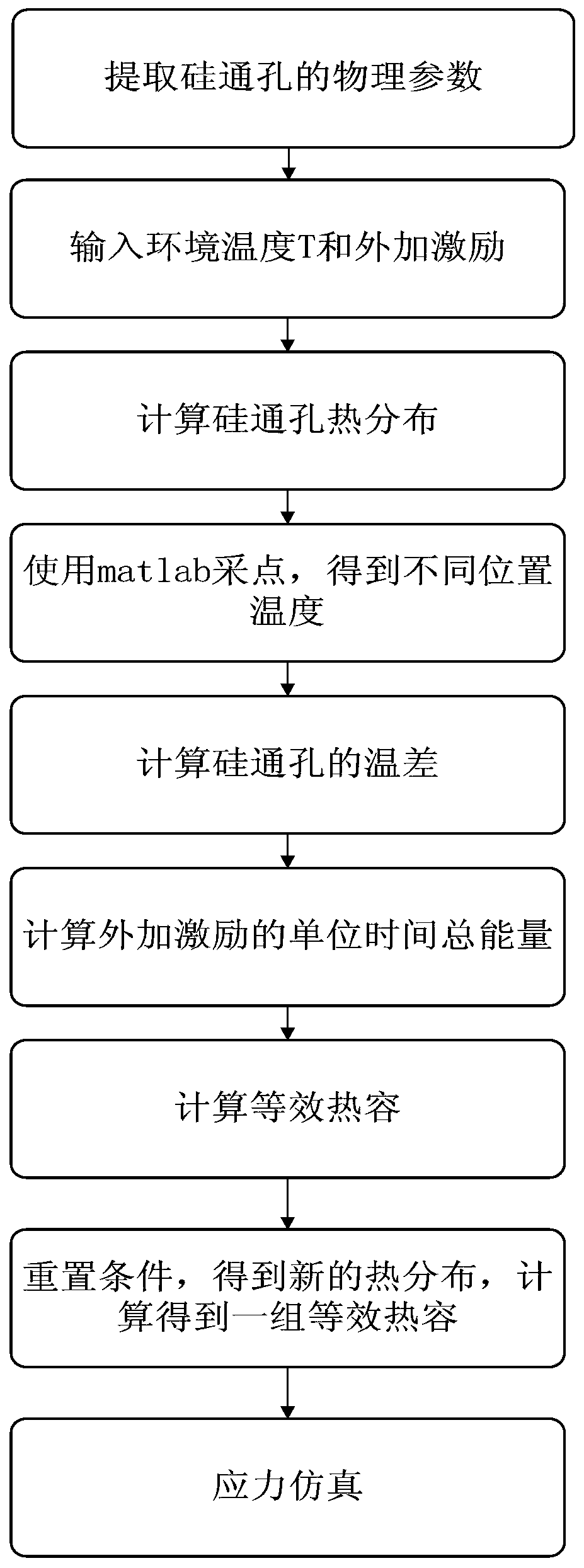

[0040] refer to figure 1 , the concrete realization of the present invention is as follows:

[0041] Step 1. Extract the physical parameters of the materials inside and outside the TSVs in the circuit.

[0042] Extract the physical parameters of the inner and outer layers of the TSV used in the circuit, the physical parameters include: the radius r of the upper surface of the TSV Cu1 , the lower surface radius r of the TSV Cu2 , the height H of the TSV, the resistance R of the copper pillar of the TSV, and the angle θ between the side surface and the bottom surface of the TSV 1 , r Cu1 Equal to the radius of the upper surface of the TSV copper pillar plus the thickness of the silicon dioxide on the upper surface of the TSV, r Cu2 It is equal to the radius of the lower surface of the TSV copper pillar plus the thickness of silicon dioxide on the lower surface of the TSV.

[0043] Step 2. Enter the ambient temperature T and external excitation used in the TSV.

[0044] Ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com