Method for multi-objective quality comprehensive evaluation optimization of injection molding technology

An injection molding process and comprehensive evaluation technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of slow neural network learning speed and reduced prediction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

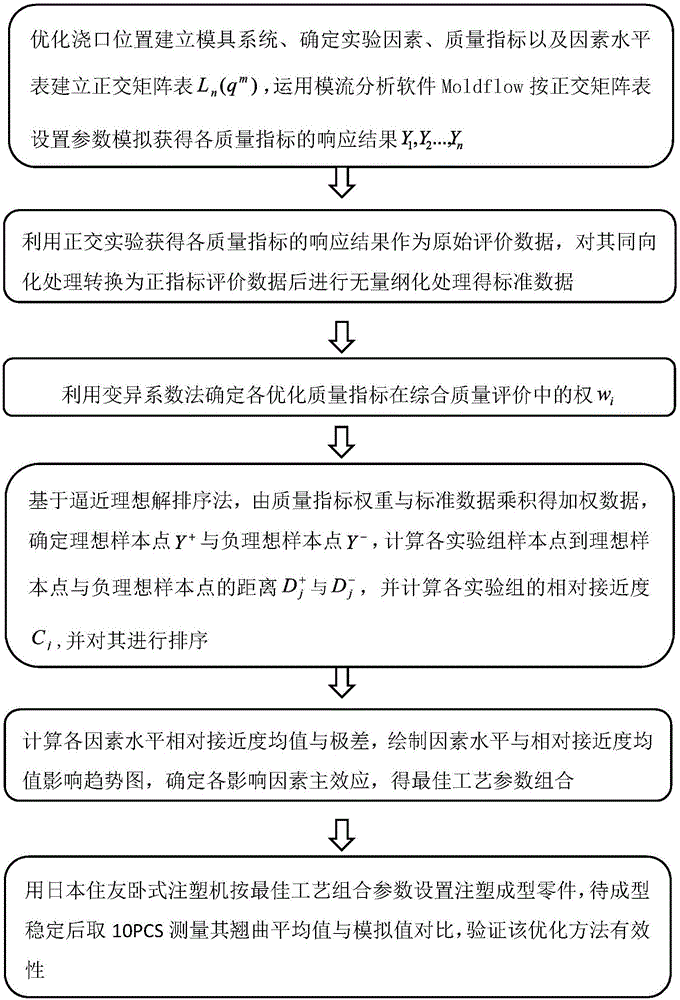

[0055] Aiming at the defects of multiple quality indicators such as warping and deformation of plastic parts, volume shrinkage during ejection, and depth of sink marks, the present invention is based on orthogonal experiments, and uses the method of combining the variation coefficient method and the approach to the ideal solution sorting method to analyze the injection molding process. Multi-objective comprehensive evaluation optimization.

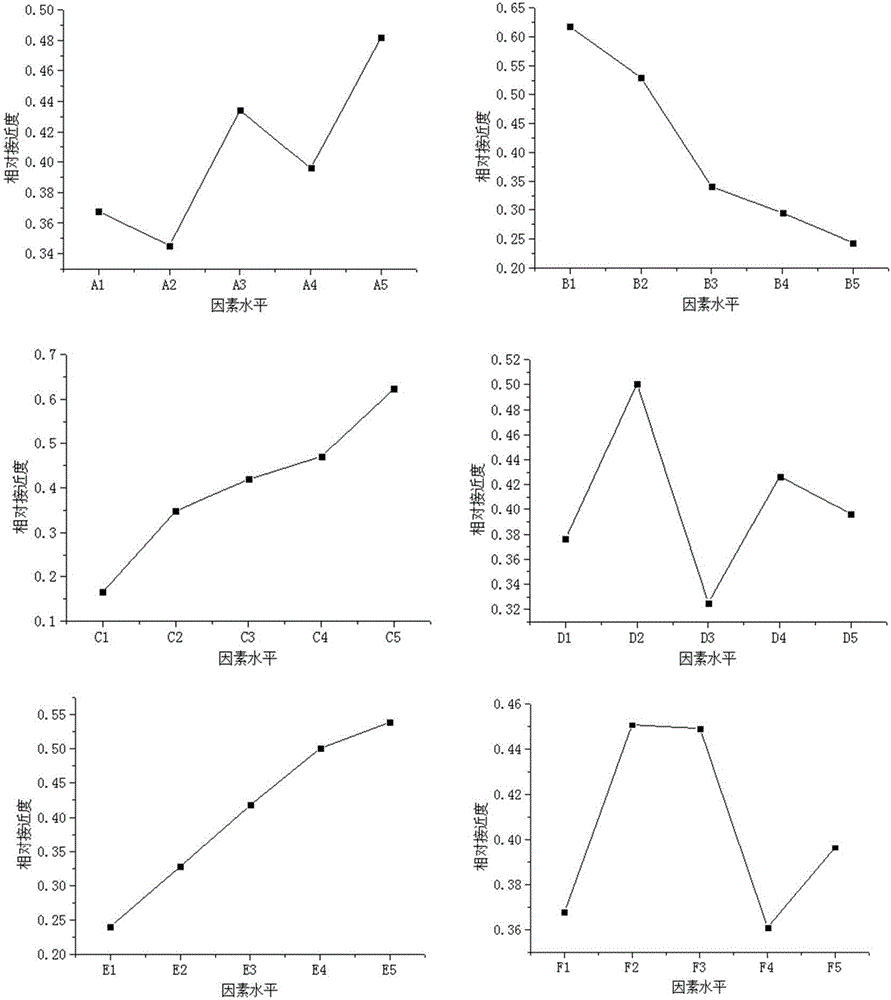

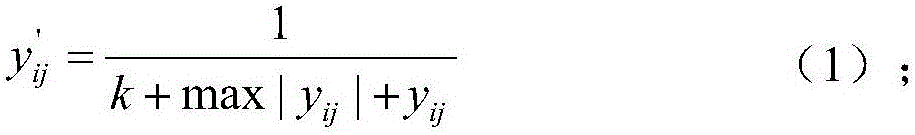

[0056] Using the orthogonal experiment method to obtain the response data of each quality index, and then using the variation coefficient method to determine the weight of each quality index in the comprehensive evaluation quality, and then using the approximate ideal solution sorting method to calculate the relative proximity of each sample point to the ideal sample point and Sort the experimental sequence according to the relative proximity, the better, and then calculate the relative proximity mean value and range of each factor level, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com