Model selection comparison test and motion parameter determination method for electric machine and driver thereof

A technology of motor drivers and motion parameters, which is applied in the field of automation technology and advanced manufacturing, and can solve the problems of no quantitative evaluation standards and evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

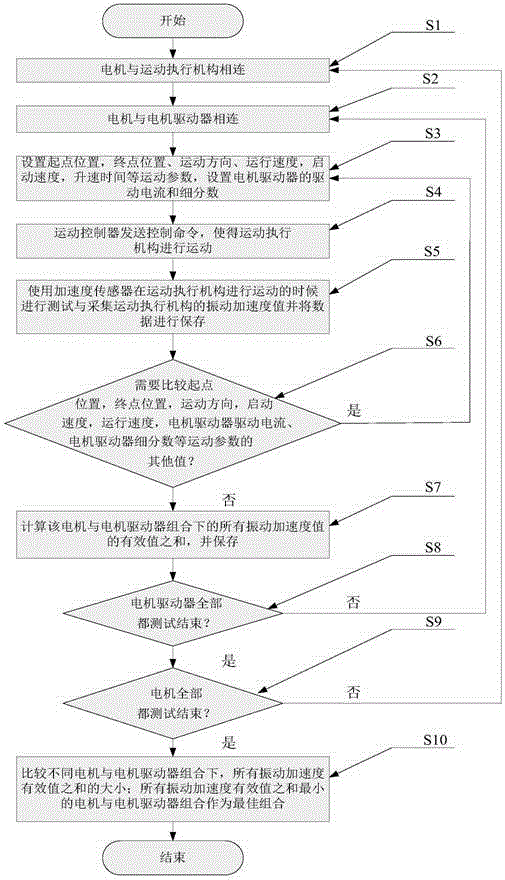

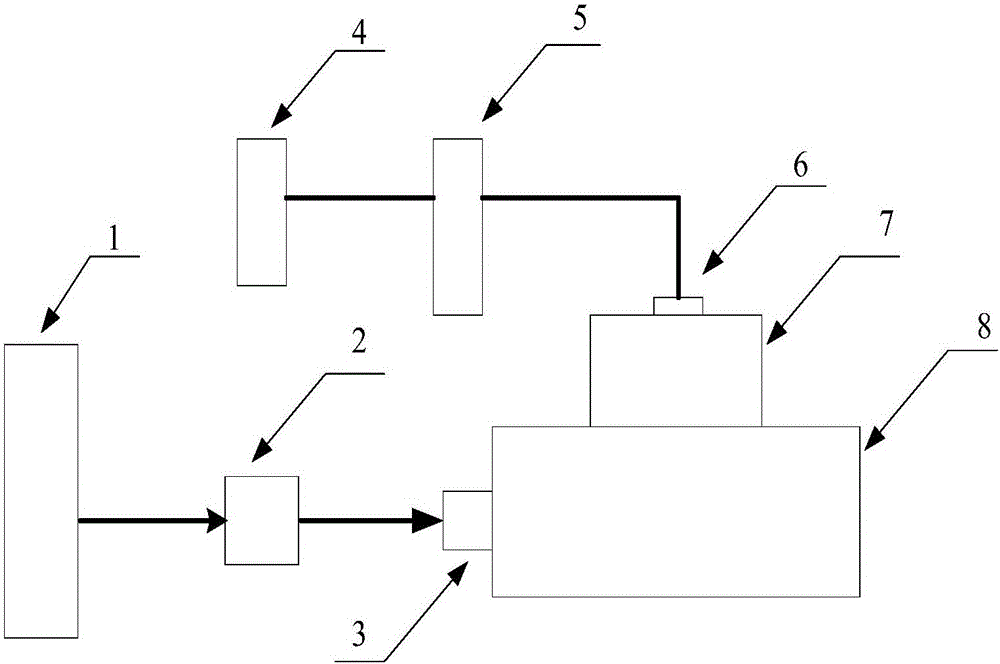

[0024] figure 1 It is a block diagram of a test system used in the type selection comparison test of the motor and its driver and the method for determining motion parameters in the present invention.

[0025] The motion control device used in the present invention includes a motion controller 1 , a host computer 4 , a data acquisition card 5 , an acceleration sensor 6 , a load 7 , and a motion actuator 8 . The pulse and direction control signals sent by the motion controller 1 are connected to the motor driver 2; the driving signal of the motor driver 2 is connected to the motor 3; the motor 3 is connected to the motion actuator 8; the acceleration sensor 6 is connected to the data acquisition card 5; the data acquisition card 5 is connected with the upper computer 4; the load 7 is fixed on the motion actuator 8, and the characteristic is that the method includes the following steps:

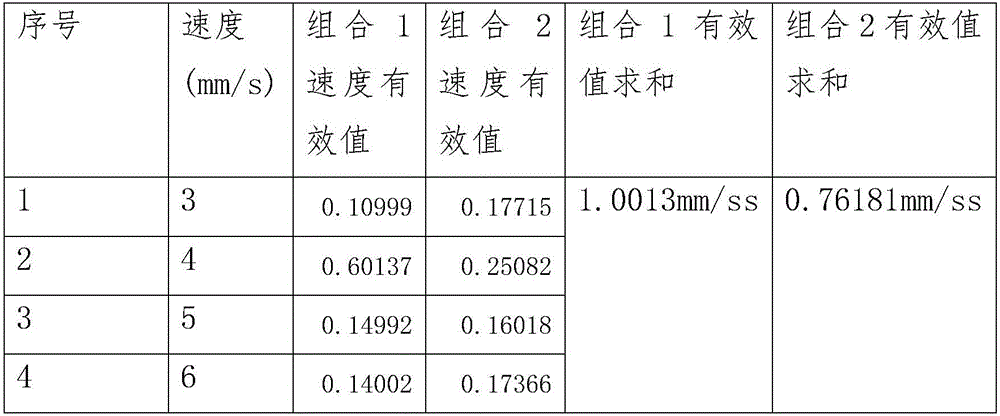

[0026] In this embodiment, two types of motor drivers 2-1 and 2-2 and one type of motor 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com