Tensile testing device for flexible hinge micro-components with clamping centering guide

A flexible hinge and tensile testing technology, used in measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc. Micro-displacement loading, complex sample preparation, etc., to achieve the effects of low cost, overcoming experimental errors, and convenient experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

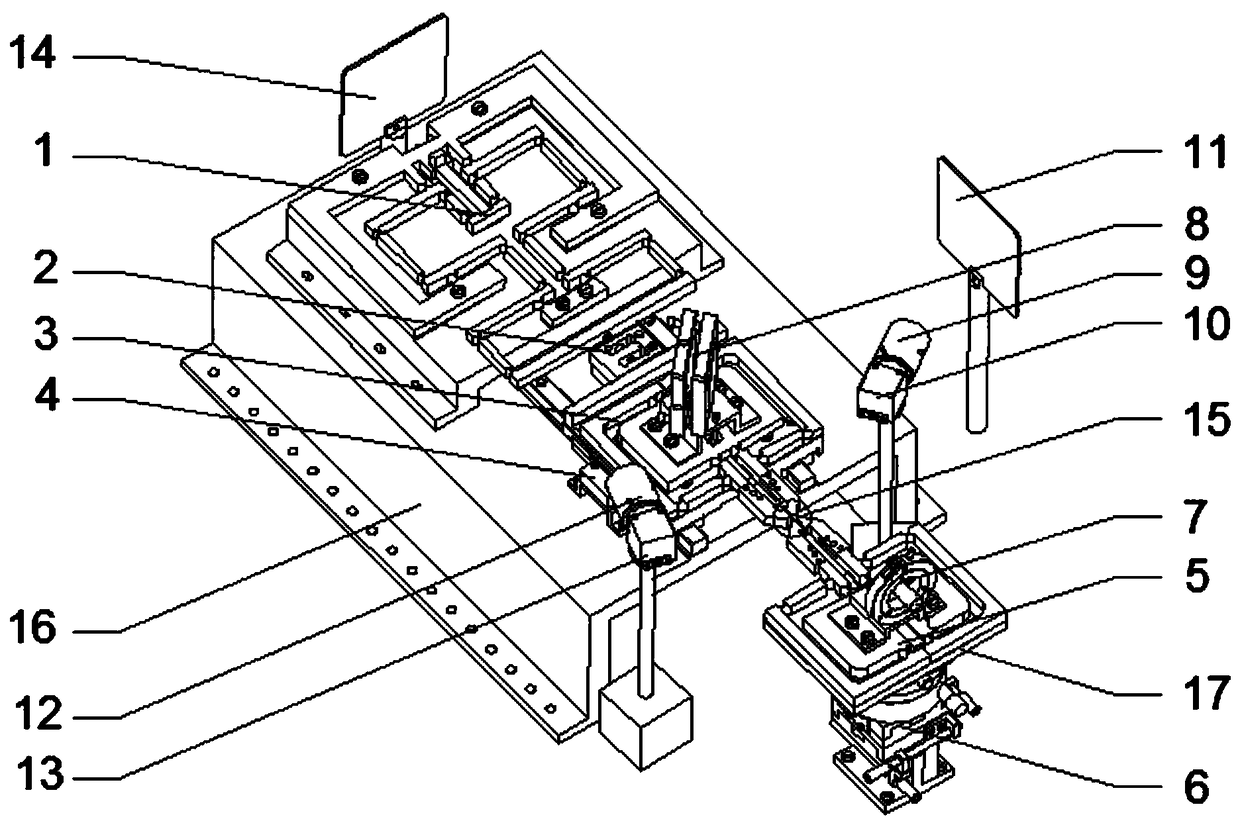

[0038] like figure 1 As shown, in this embodiment, the flexible hinge micro-component tensile test device with clamping and centering guidance includes: a movable end clamping mechanism 3, a fixed end clamping mechanism 5, a loading mechanism 1, a centering mechanism, and a tension sensor 2 , grating sensor 4, movable end supporting mechanism 16 and fixed end supporting mechanism;

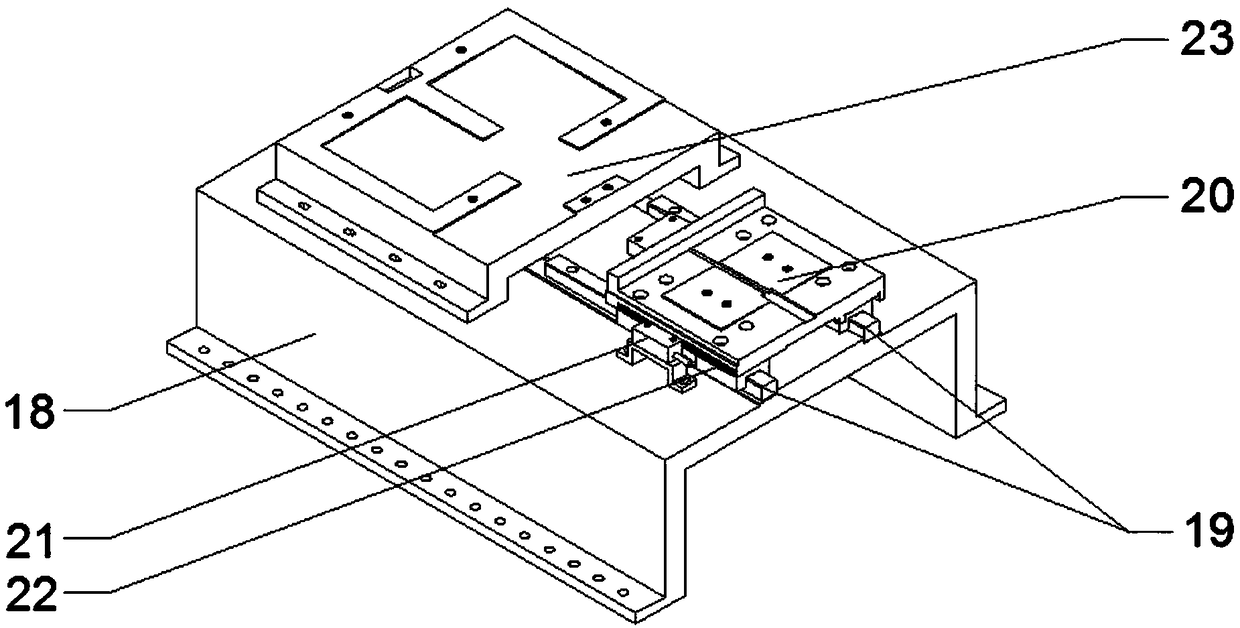

[0039] like Figure 2a As shown, the movable end support mechanism 16 includes: a loading mechanism workbench 23, a base 18, a movable end clamping mechanism workbench 20 and a precision linear guide rail 19;

[0040]A loading mechanism workbench 23 and a precision linear guide rail 19 are respectively arranged on the base 18, and the symmetry axes of the loading mechanism workbench 23 and the precision linear guide rail 19 are on the same vertical plane; The clamping mechanism workbench 20; the movable end clamping mechanism 3 is arranged on the movable end clamping mechanism workbench 20, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com