Combined type vibration isolating device used for transformer

A transformer and combined technology, applied in the direction of transformer/reactor installation/support/suspension, spring/shock absorber, vibration suppression adjustment, etc. The effect of low natural frequency and wide vibration isolation frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

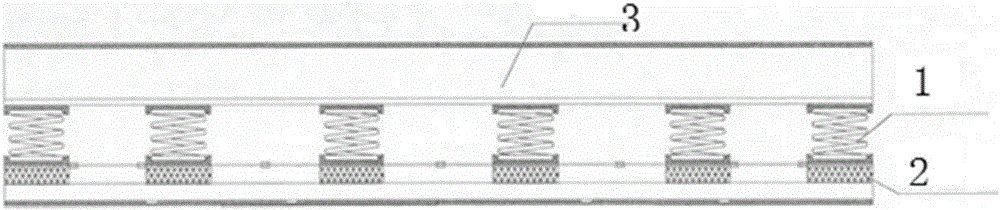

[0025] Such as figure 1 Shown is the combined vibration isolation device for the transformer provided in this embodiment, including a spring vibration isolator and a rubber vibration isolator. The spring vibration isolator is located on the upper layer of the rubber vibration isolator and is connected to the transformer frame , the rubber vibration isolator is located on the ground, the spring vibration isolator includes at least 2 spring vibration isolation elements 1, the rubber vibration isolator includes at least 2 rubber vibration isolation elements 2, the number of spring vibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com