Production equipment and construction method of soil matrix artificial turf

A technology for artificial turf and production equipment, which is applied to roads, pavements, roads, etc., can solve problems such as large impact, low construction efficiency, and inability to use combined cutting tools, so as to reduce impact, simplify construction steps, improve laying efficiency and The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

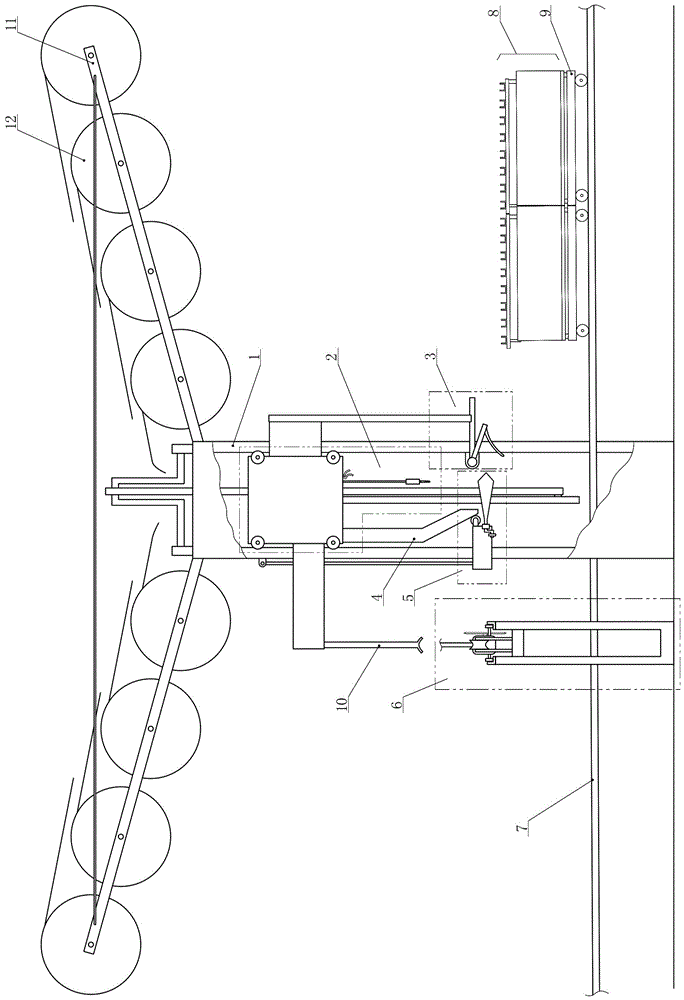

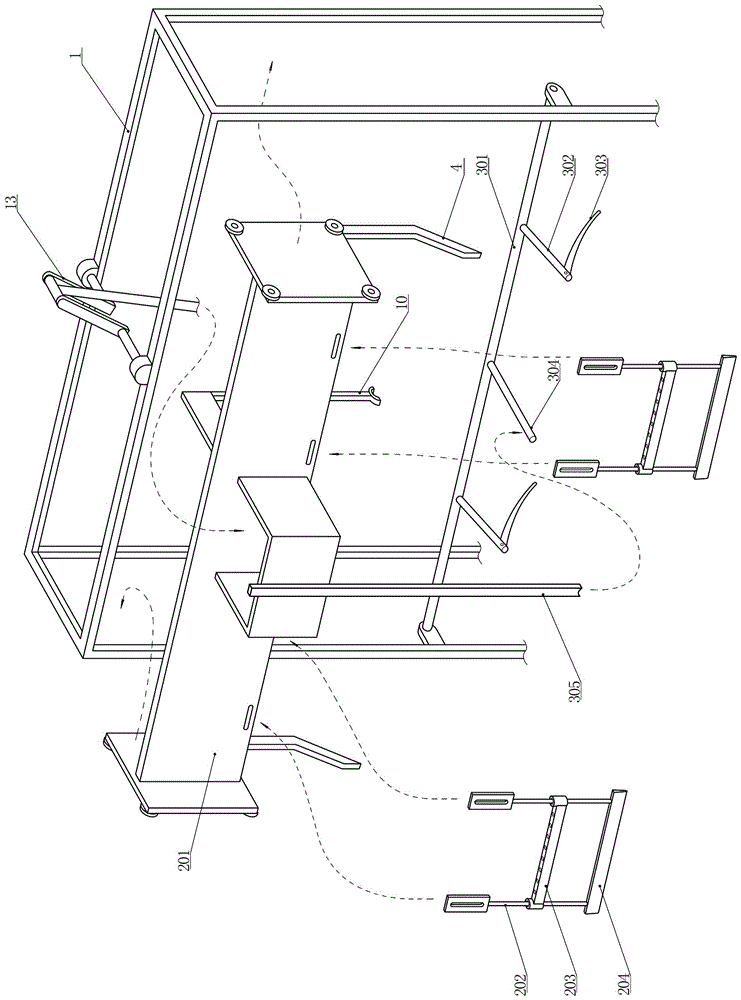

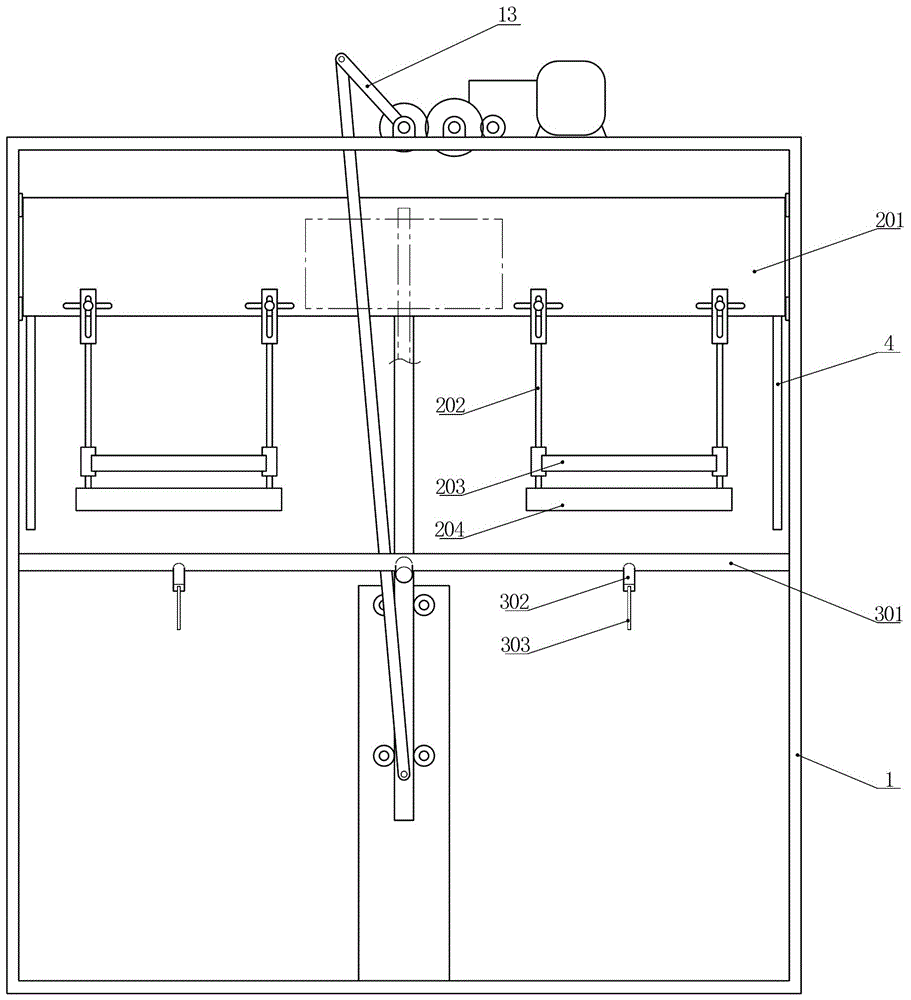

[0046]The present invention comprises a power device, a control device, a main frame 1, a track 7, a grass rack 11 for supporting a grass reel 12 (package grass), a cutting mechanism 2, an escapement mechanism 5, a stepping mechanism 3, Clay plate assembly 8, step trolley 9, shredding mechanism 6.

[0047] from Figure 1 to Figure 9 It can be seen that the present embodiment takes two grass silk mud blank processing production lines as an example to improve processing efficiency. The main frame 1 is symmetrically provided with two grass silk mud blank production lines, and a set of control mechanism and power device are used to control the two production lines to work synchronously;

[0048] The grass wire rack 11 is fixed on the top of the main frame 1, and the grass wire rack is equipped with a plurality of grass wire reels 12 and conduits for threading the grass wires, and each grass wire reel corresponds to a conduit to prevent multiple grass wires from being entangled wit...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that the escapement frame 501 of the escapement mechanism is slidably matched with the main frame 1 through the slide rail; Hinged, eliminating the need for guide rods and roller guide mechanisms; the connection mode between the shredder 603 and the control device is that the shredder 603 is connected with the motor through a rack and pinion or a belt transmission mechanism, and the reciprocating motion of the shredder 603 is controlled to realize Shred work.

[0074] Other technical features of this embodiment are the same as those of Embodiment 2.

[0075] The production and laying steps of soil matrix artificial turf:

[0076] (1) Preparatory work: including collecting soil, sieving soil, and mud; sieve the soil together, remove massive impurities, add water to stir and mud; level off the paving site, compact it, and set signs;

[0077](2) Mud supply: Place the stepping trolley on the track, and connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com