Method of operating ingots on tow-for-one twisting or doubler twisting machine

一种并捻机、锭子的技术,应用在操作倍捻或并捻机的锭子领域,能够解决气圈线导引件单独控制不可行等问题,达到小能量消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

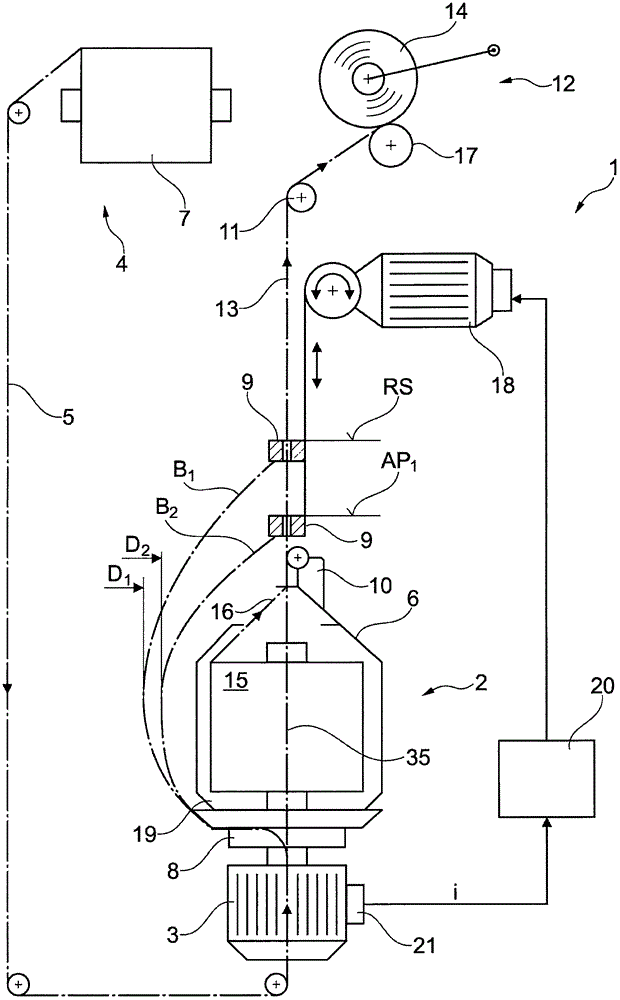

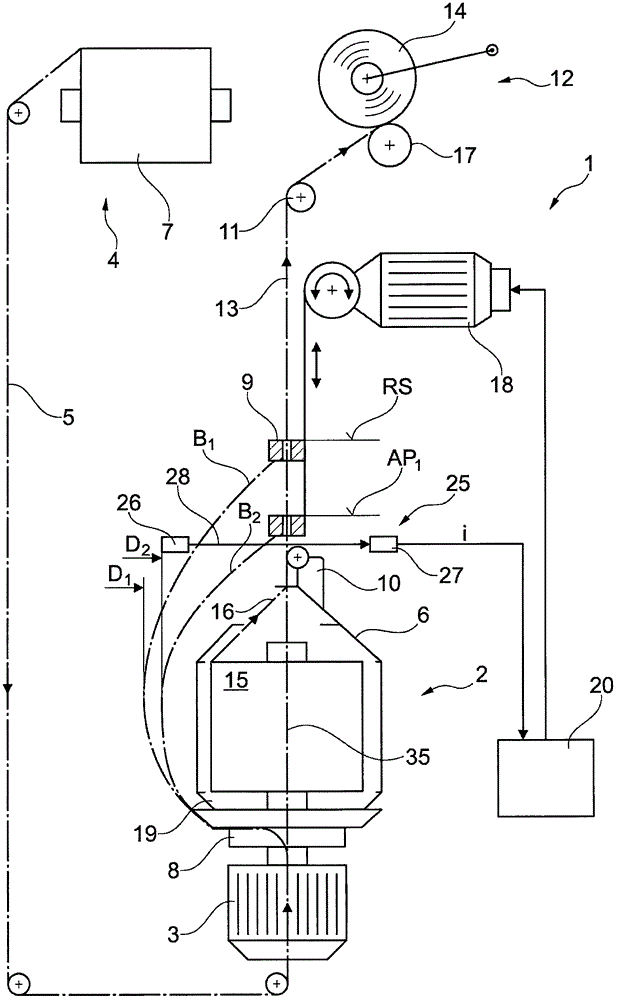

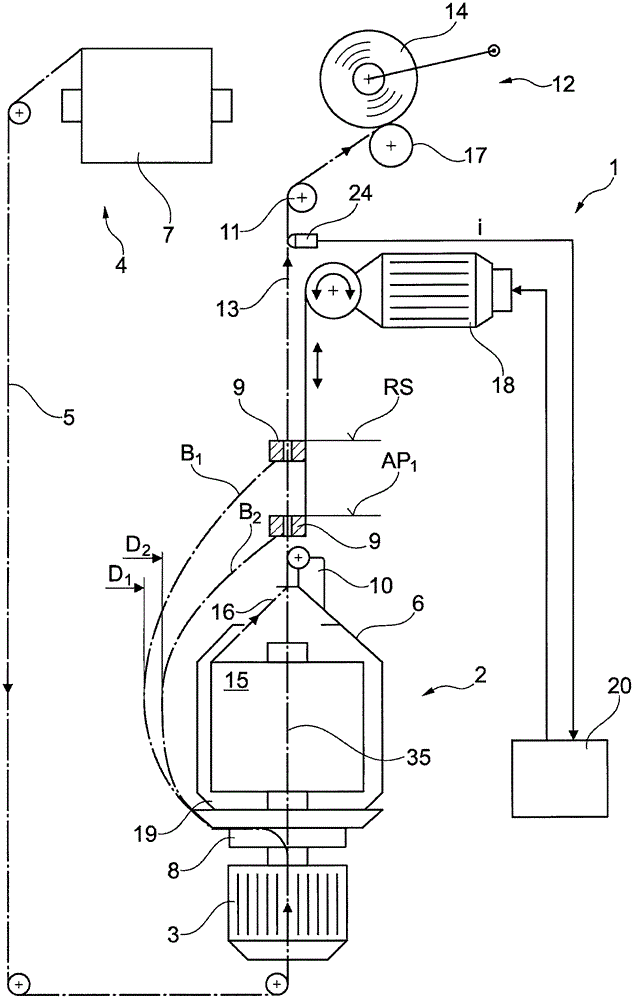

[0066] figure 1 A schematic side view of a workstation 1 of a two-for-one or cabling machine is shown.

[0067] In the exemplary embodiment, the workstation 1 is equipped with a spindle 2 configured as a cascading spindle.

[0068] The workstation 1 comprises a balloon thread eyelet 9 which is adjustable in height by means of an adjustment drive 18 and which can be selectively assumed in an initial position designated as rest position RS or in a first operating position AP 1 .

[0069] In this context, the regulating drive 18 is connected to a control circuit 20 which is further connected to a device 21 for generating a measured value i.

[0070] Above or behind the workstation 1 there is located a bobbin rack 4 (not shown in more detail), which generally serves to accommodate several feed bobbins 7 .

[0071] From one of these feeding bobbins 7 (hereinafter referred to as the first feeding bobbin 7), the so-called outer thread 5 is drawn, which is deflected several times i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com