Point welding fixture for rotor ventilating slot piece and ventilating slot strip and using method of point welding fixture

A technology of ventilation slots and rotors, applied in manufacturing tools, welding equipment, welding equipment, etc., can solve problems such as increased rework costs, reduced work efficiency, and weak solder joints, so as to improve manufacturing quality, work efficiency, and improve points The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

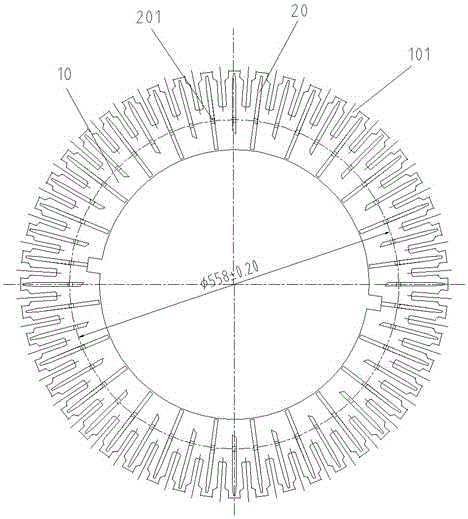

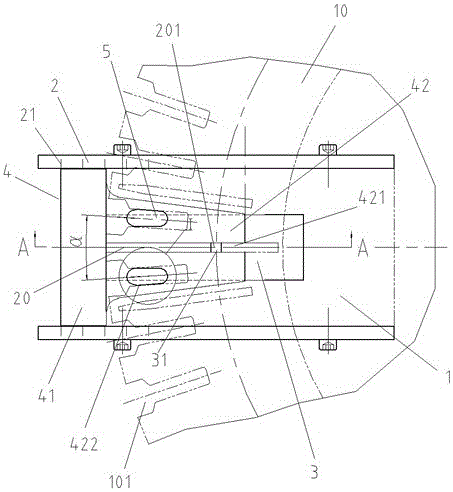

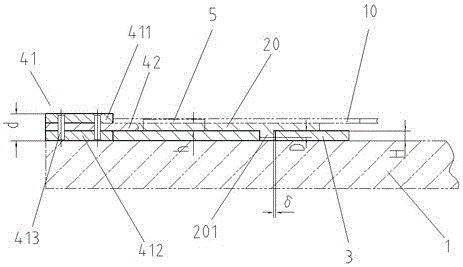

[0029] Such as Figure 2 ~ Figure 4 As shown, the spot welding fixture of the rotor ventilation slots and ventilation slots in this embodiment includes a spot welding machine copper base plate 1, a pair of moving guide rails 2, a copper backing plate 3, a rotor ventilation slot positioning piece 4 and two positioning blocks 5. The moving guide rail 2 is strip-shaped, and its longitudinal lower part is respectively fixed on the longitudinal two sides of the copper base plate 1 of the spot welding machine by fastening screws. The rotor ventilation slot positioning piece 4 is T-shaped, including a rear positioning plate 41 and a ventilation slot positioning plate 42 vertically extending outward from the middle of the rear positioning plate 41. The ventilation slot positioning plate 42 is provided with a ventilation slot in the longitudinal center. The width of the bar 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com