Automobile hub coating line horizontal cableway rotation station

A technology of automobile wheel hub and rotating station, applied in the direction of spraying device, etc., can solve the problems of sagging and spray leakage, and achieve the effect of simple structure, avoidance of spray leakage, and exquisite device design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

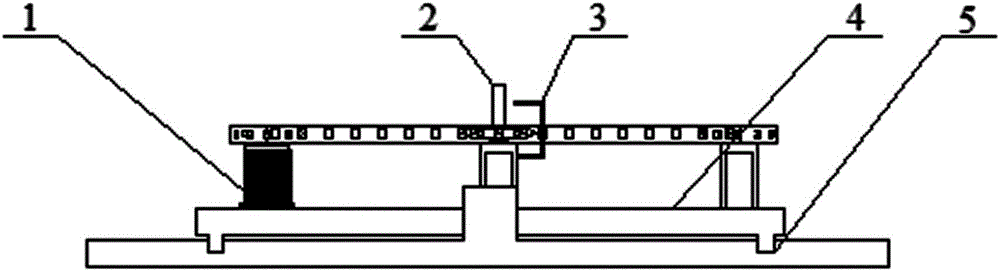

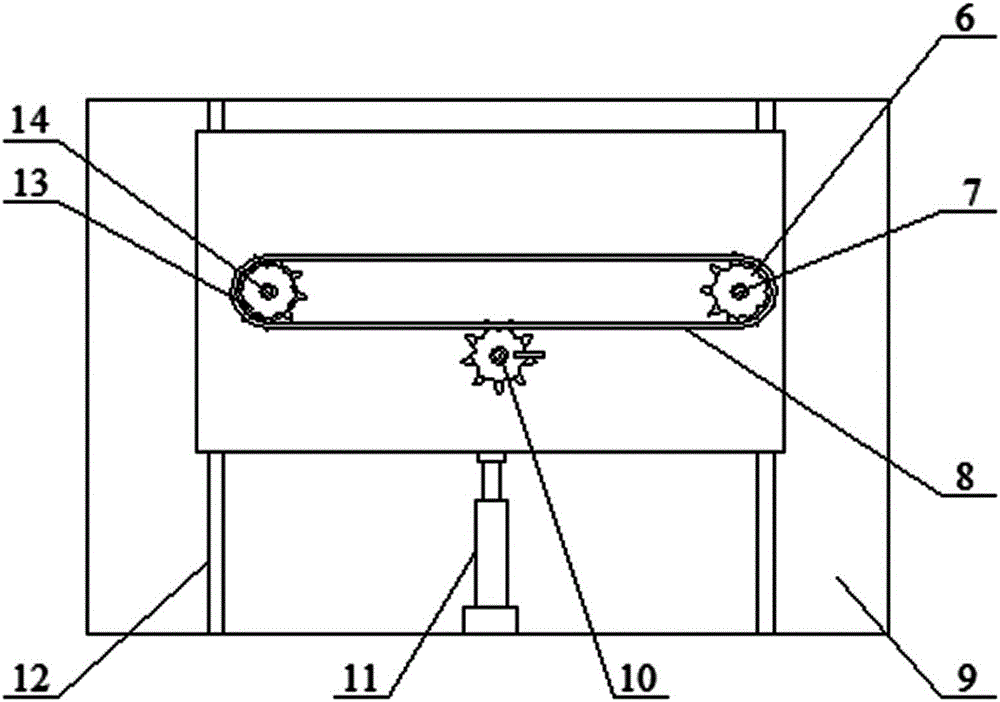

Embodiment 1

[0015] The horizontal cableway rotary station of a kind of automobile wheel hub coating line in this embodiment consists of a rotary station motor (1), a cableway hanger (2), a hanger speed measuring device (3), a supporting plate (4), and a supporting plate boss (5), rotary station chain driven gear (6), driven gear shaft (7), rotary station chain (8), rotary station base plate (9), cableway hanger gear (10), push cylinder (11), The rotary station bottom plate slideway (12), the rotary station motor driving gear (13) and the rotary station motor driving gear shaft (14), are characterized in that two rotary station bottom plate slideways (12) are processed on the rotary station bottom plate (9) ), the supporting plate (4) is installed on the rotating station floor (9) through the rotating station floor slideway (12); one end of the push cylinder (11) is fixed to the rotating station floor (9), and the output end is fixed to the supporting plate ( 4), and it is set so that when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com