Composite Hydrate Additive and Its Application in Mixed Gas Separation and Enrichment

A kind of hydrate and composite technology, which is applied in the direction of separation method, gas treatment, carbon compound, etc., can solve the problems of industrialization of hydrate technology, low gas storage capacity, high production cost, etc., and achieve poor separation effect, simple purification method, The effect of fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

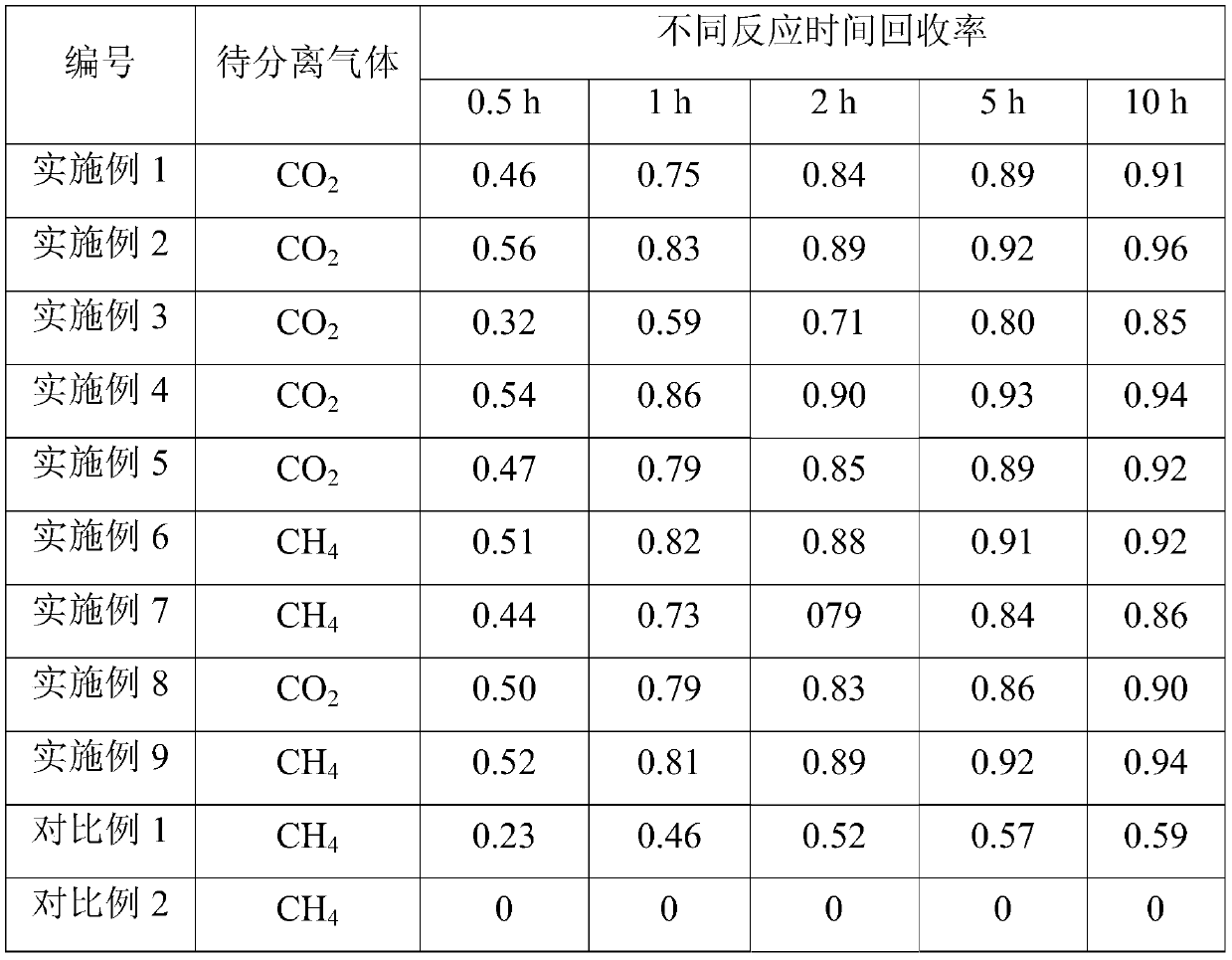

Embodiment 1

[0028] In this example, a composite additive with a mass fraction of 0.2% tryptophan and 0.5% THF was used as the hydration accelerator.

[0029] 1) Uniformly mix 0.2g tryptophan, 0.5g THF and 99.3g water to obtain a composite additive aqueous solution with a mass fraction of 0.7%, that is, a composite hydrate accelerator;

[0030] 2) Add 100 g of the above aqueous solution to the autoclave (500 mL effective volume);

[0031] 3) At a temperature of 273K, filling the autoclave with a mixed gas with a pressure of 7 MPa (volume fraction of 60% CO 2 , with a volume fraction of 40% N 2 ), calculate the CO in the mixed gas at a certain time interval by the change of the pressure in the reactor 2 The content changes, the results are shown in Table 1;

[0032] 4) Under normal temperature and pressure, the gas hydrate naturally decomposes to obtain high-purity CO 2 gas.

Embodiment 2

[0034] In this example, a composite additive of 0.5% tryptophan and 1% THF was used as the hydration accelerator.

[0035] 1) Uniformly mix 0.5g tryptophan, 1g THF and 98.5g water to obtain a composite additive aqueous solution with a mass fraction of 1.5%, that is, a composite hydrate accelerator;

[0036] 2) Add 100 g of the above aqueous solution to the autoclave (500 mL effective volume);

[0037] 3) at a temperature of 273K, filling the autoclave with a pressure of 5 MPa mixed gas (35% CH 4 , 65% CO 2 ), calculate the CO in the mixed gas at a certain time interval by the change of the pressure in the reactor 2 The content changes, the results are shown in Table 1;

[0038] 4) Under normal temperature and pressure, the gas hydrate naturally decomposes to obtain high-purity CO 2 gas.

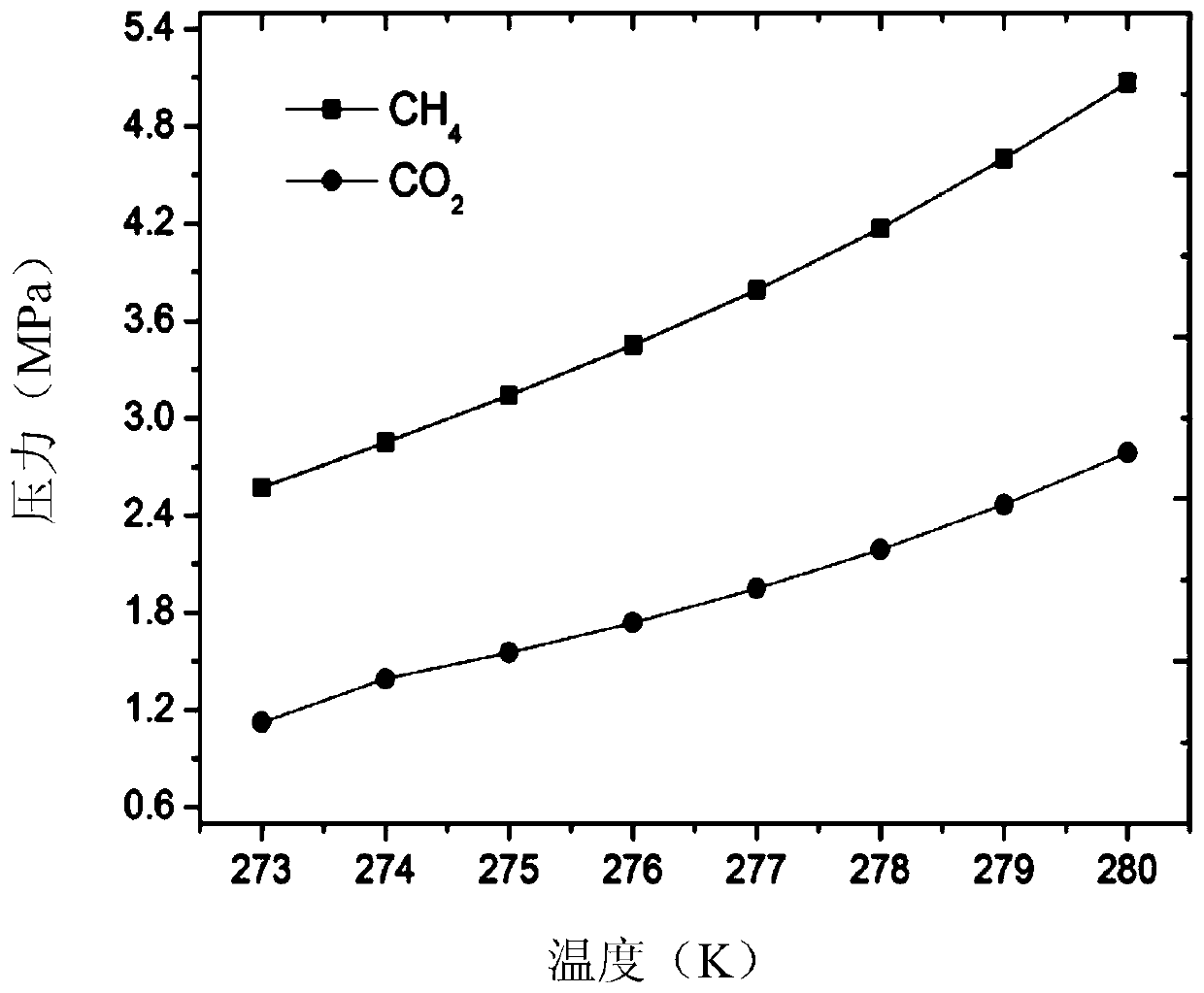

[0039] Each gas (CH) in the mixed gas in this embodiment 4 and CO 2 ) hydrate phase equilibrium curve such as figure 1 shown.

Embodiment 3

[0041] In this example, a composite additive with a mass fraction of 0.1% tryptophan and 0.4% TiAAB was used as a hydrate accelerator.

[0042] 1) Uniformly mix 0.1g tryptophan, 0.4g TiAAB and 99.5g water to obtain a composite additive aqueous solution with a mass fraction of 0.5%, that is, a composite hydrate accelerator;

[0043] 2) Add 100 g of the above aqueous solution to the autoclave (500 mL effective volume);

[0044] 3) At a temperature of 274K, it is 7 MPa mixed gas (40% CO 2 , 60%N 2 ), calculate the CO in the mixed gas at a certain time interval by the change of the pressure in the reactor 2 The content changes, the results are shown in Table 1;

[0045] 4) Under normal temperature and pressure, the gas hydrate naturally decomposes to obtain high-purity CO 2 gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com