Buckwheat dibbling sowing mechanism

A technology for sowing mechanism and buckwheat, which is applied to fertilizers and sowing equipment, etc., can solve the problems of low labor efficiency, consuming a lot of manpower, and a lot of labor, and achieve the effect of saving labor, improving work rate, and not easy to stick soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

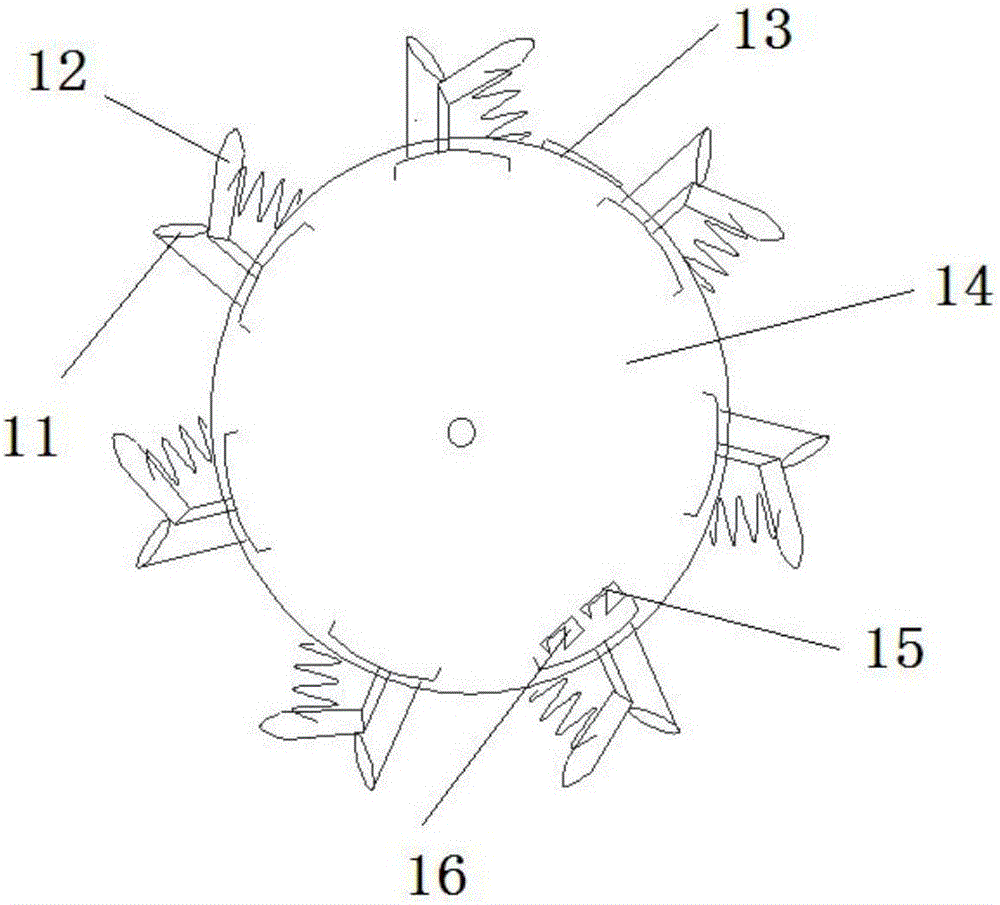

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

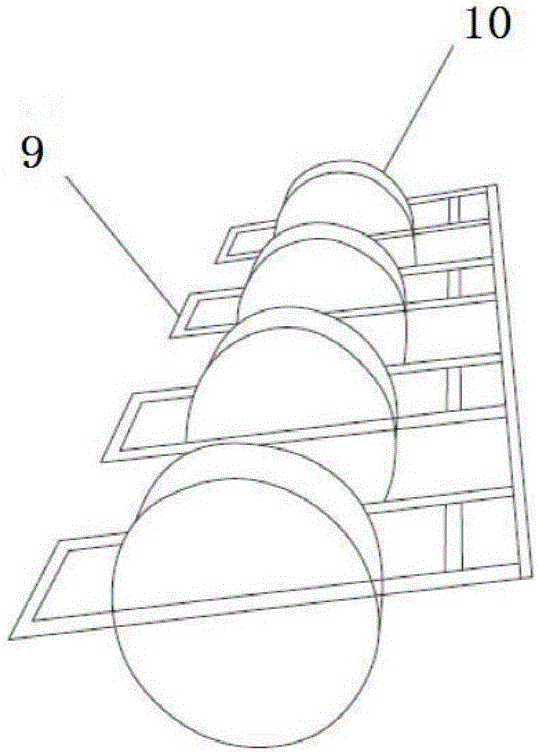

[0024] A buckwheat on-demand sowing mechanism provided by the present invention includes a car body, a ground leveling device is installed on the rear frame of the car body, and a sowing device is installed on the ground leveling device.

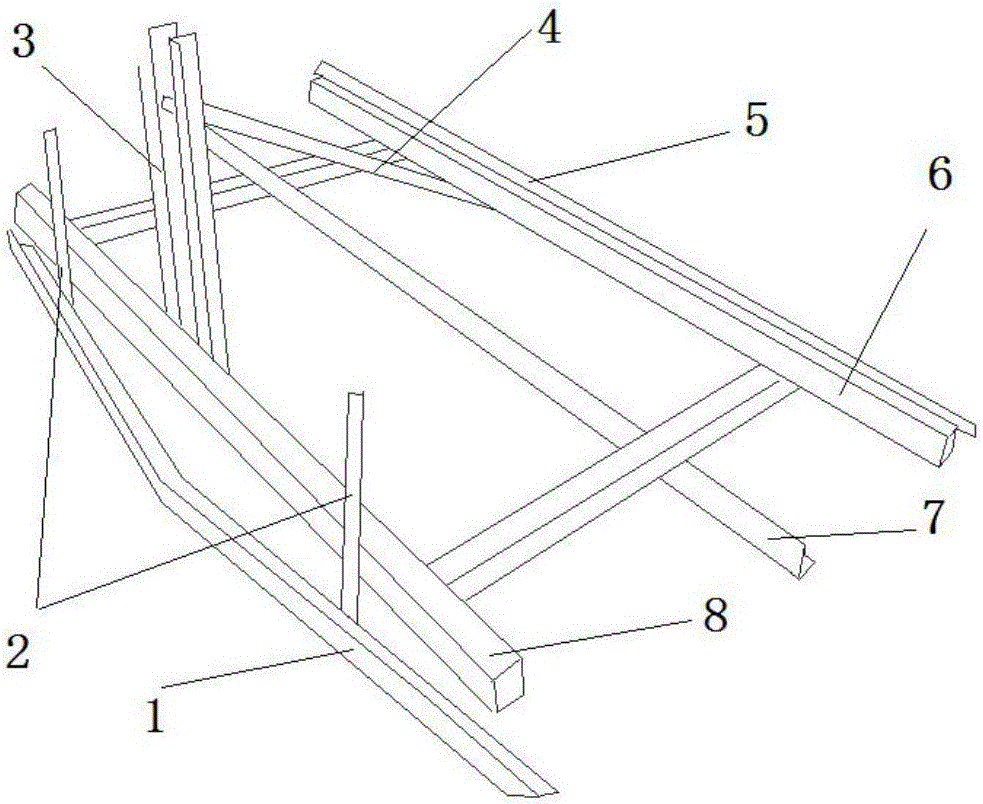

[0025] Such as figure 1 As shown, the leveling device includes a first suspension beam 6 and a second suspension beam 8, the first suspension beam 6 and the second suspension beam 8 are placed in parallel, and both ends are connected by connecting pieces, and the two suspension beams A third suspension beam 7 is also installed between the two connectors, and the third suspension beam 7 is parallel to the first suspension beam 6 and the second suspension beam 8 .

[0026] The second hanging beam 8 is provided with two fixed rods 2, on which a scraper bar 1 is installed, and the scraper bar 1 is slidably connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com