Crawler vehicle drive system and crawler vehicle comprising such a drive system

A vehicle drive and drive system technology, applied to tracked vehicles, vehicle components, construction vehicles, etc., can solve the problems of accelerated drive system wear, damage to comfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

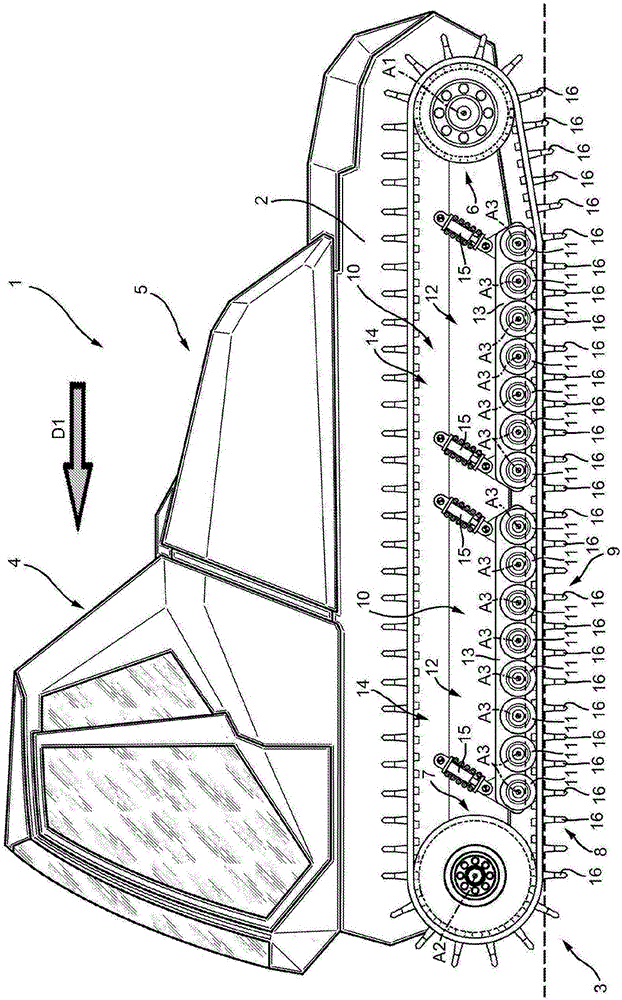

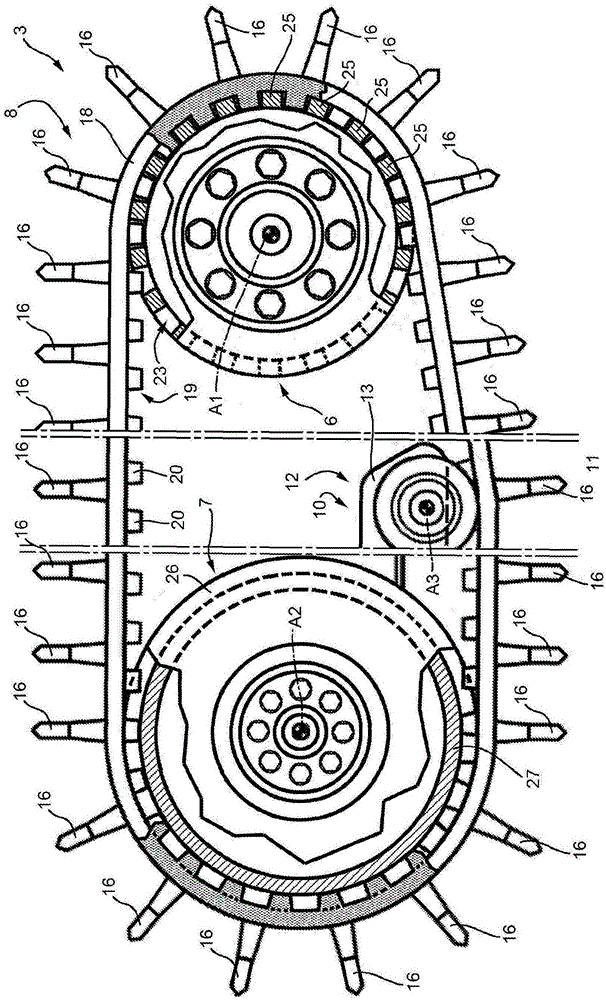

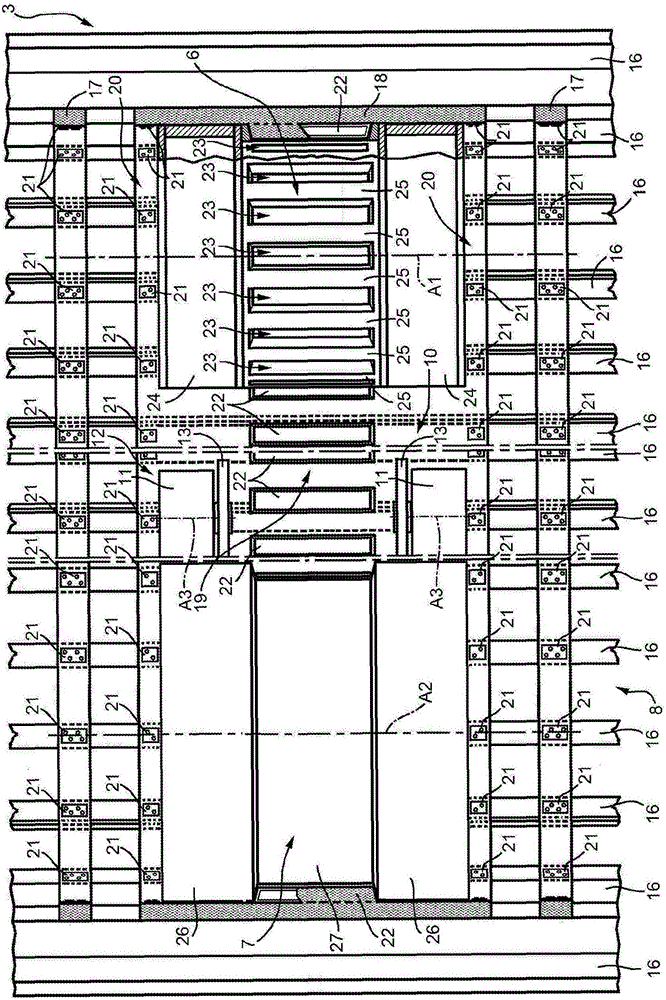

[0035] refer to figure 1 , as a whole, reference numeral 1 designates a tracked vehicle for clearing ski slopes and designed to move in a forward direction D1. A tracked vehicle 1 comprises a frame 2; two drive systems 3 ( figure 1 only one shown in ); the cabin 4; and the engine 5. Each drive system 3 includes a drive wheel 6; an idler wheel 7;

[0036] Each drive wheel 6 corresponds to a rear wheel of the tracked vehicle 1 , rotates about an axis of rotation A1 , and is driven by a preferably hydraulic or electric actuator, not shown in the figures.

[0037] Each idler wheel 7 corresponds to a front wheel of the tracked vehicle 1, rotates about an axis of rotation A2 parallel to the axis of rotation A1, and passes through the frame 2 in a selectively movable manner in two directions parallel to the forward direction D1 support to provide proper tensioning of the tracks 8 under all operating conditions.

[0038] The track 8 comprises an upper section and a lower section a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com