Short pulse laser for product composition analysis and product composition analysis method

A component analysis and laser technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problem that the repetition frequency can not be adjusted at the same time, high power, high stability ultrashort pulse laser output, laser pulse repetition The frequency cannot be easily changed, affecting the mode-locked laser pulse and other problems, to achieve the effect of improving the quality of pulse driving, promoting technological progress, and reducing difficulty requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

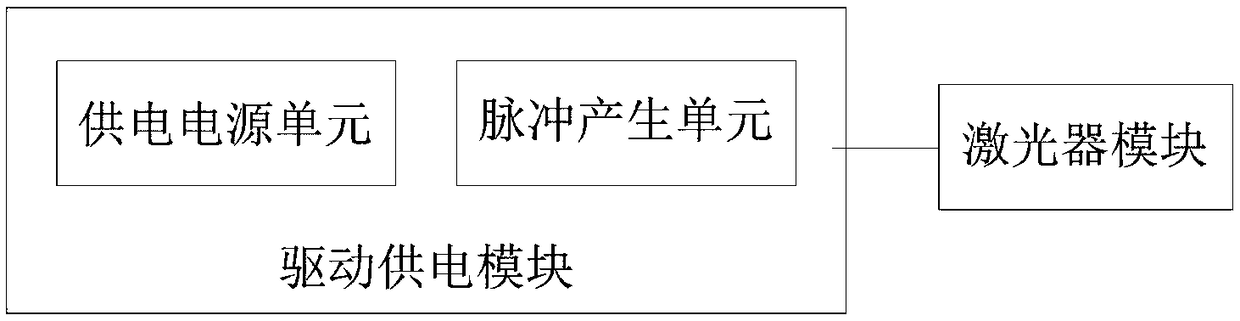

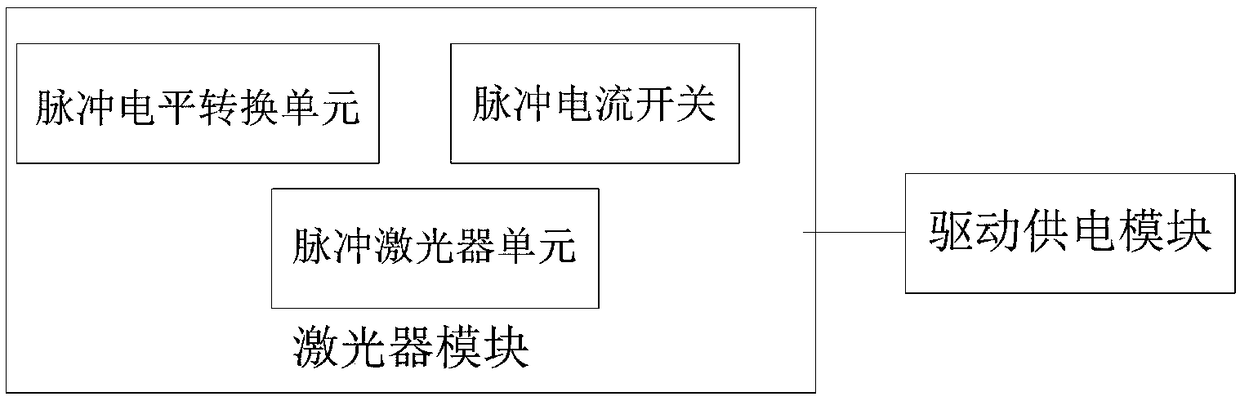

[0056] Such as figure 1 Shown is the short-pulse laser for product component analysis of the present invention, the short-pulse laser includes a drive power supply module and a laser module, the drive power supply module includes a power supply unit and a pulse generation unit, and the power supply unit is connected to the The pulse generating unit is connected, and the pulse generating unit is used to generate the electric pulse of the required pulse parameters; the laser module includes a pulse level conversion unit, a pulse current switch and a pulse laser unit, and the pulse level conversion unit is used In order to increase the electric pulse generated by the pulse generating unit to the required level to meet the driving requirements of the pulse current switch, the pulse generating unit is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com