Thermostat for permeation tube humidity generator

A technology of humidity generator and infiltration method, which is applied in the direction of instruments, scientific instruments, and analysis of gas mixtures, etc. It can solve the problems of single gas distribution, large volume, and few infiltration chambers of constant temperature heating devices, so as to achieve uniform temperature field and ensure accuracy degree, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

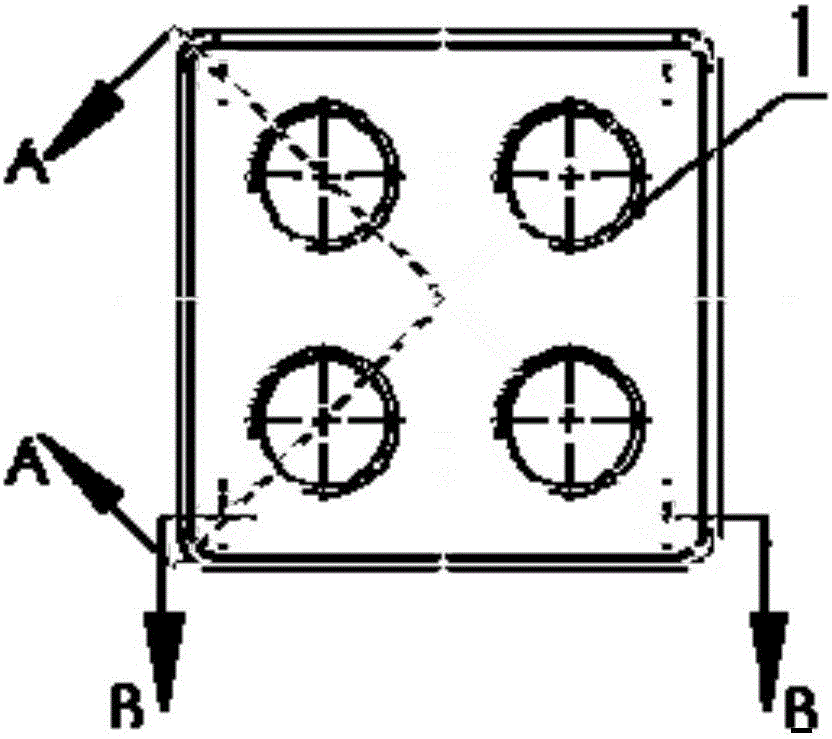

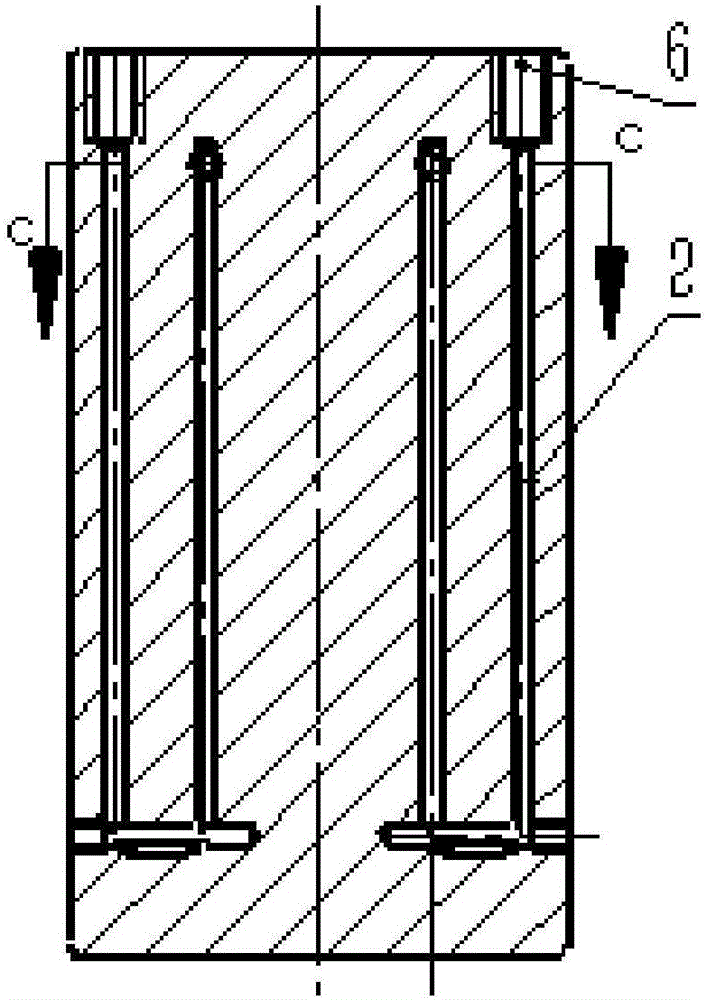

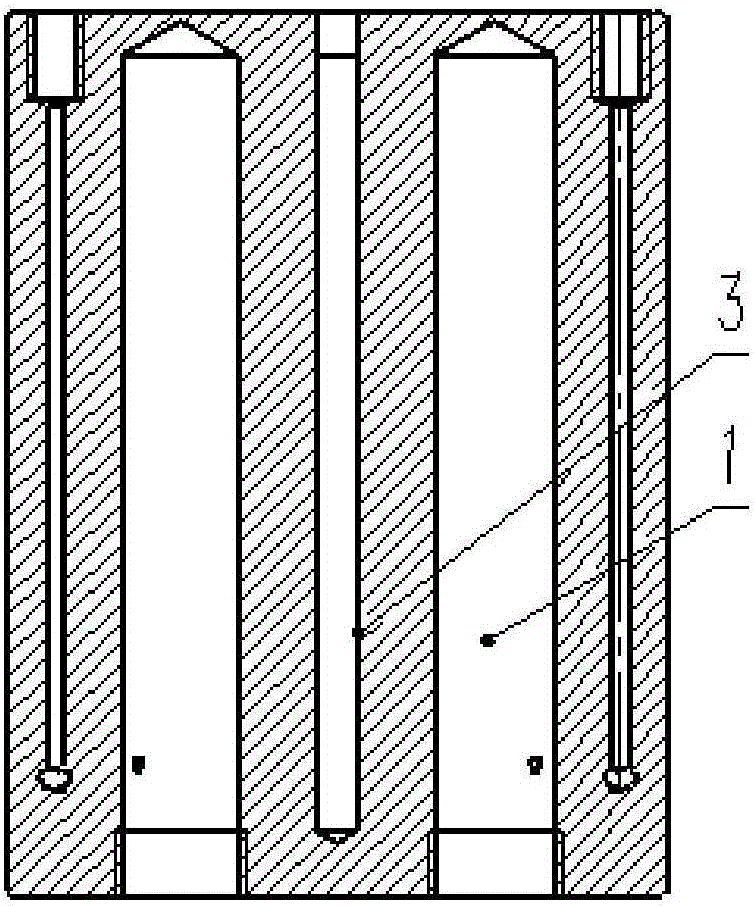

[0038] The constant temperature body for the osmotic method humidity generator proposed by the present invention has a size of 110*110*200 (mm). The constant temperature body is provided with four-way permeation chambers 1 along the top to the inside. The four-way permeation chambers 1 are completely identical and symmetrical in pairs. Clothed on the constant temperature body, the depth is 190mm. The four-way infiltration chambers are of the same size and depth, and are evenly distributed around the center. The design is compact, and its depth meets 19 / 20 of the height of the constant temperature body, basically covering the entire constant temperature body. The connection between the permeation chamber and the chamber cover is provided with an internal thread, and an o-ring platform is left, and the o-ring is compressed by screwing the thread, so that the gas flow has no attenuation. A heating rod channel 3, a temperature-controlling platinum resistance channel 4 and a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com