Rock true triaxial test method capable of realizing external loading of test specimen

A test method, true triaxial technology, applied in the preparation of test samples, measuring devices, and the use of stable tension/pressure to test the strength of materials, etc., to achieve the effect of beautiful appearance, high control precision, and complete protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

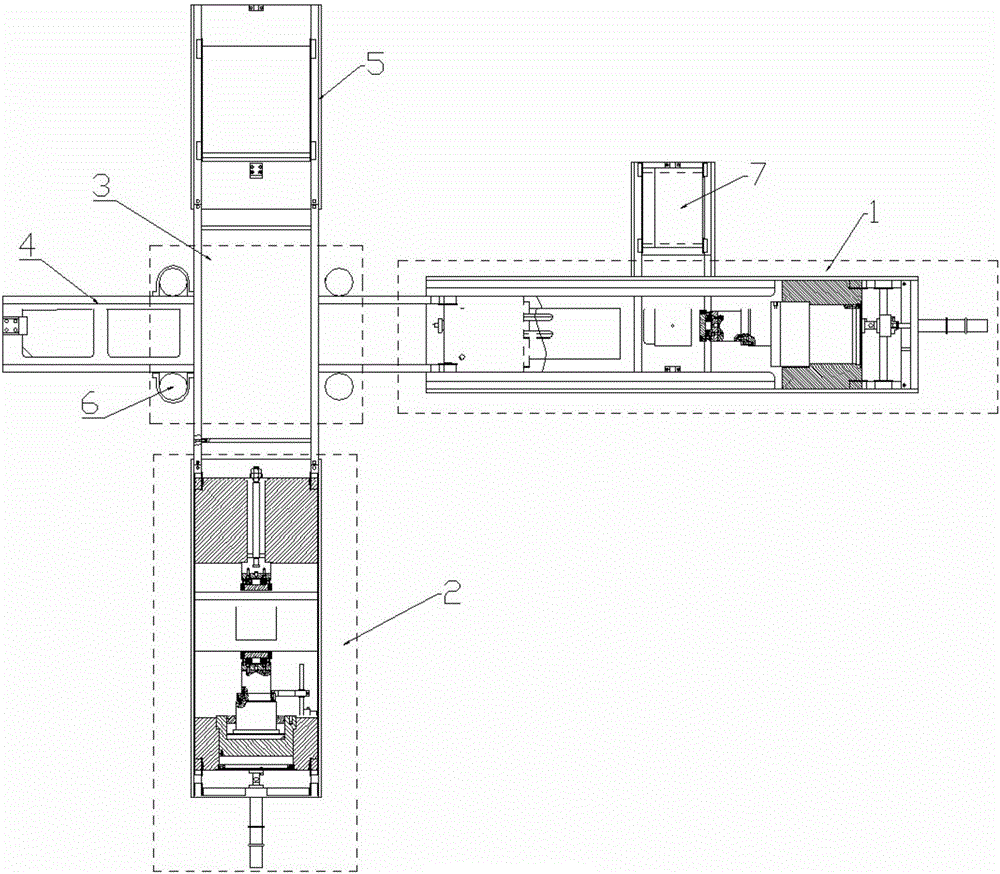

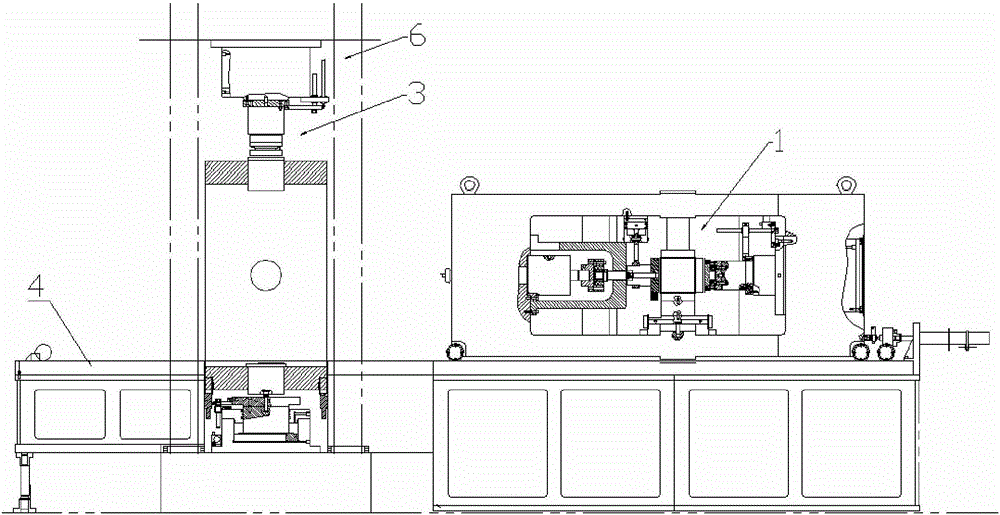

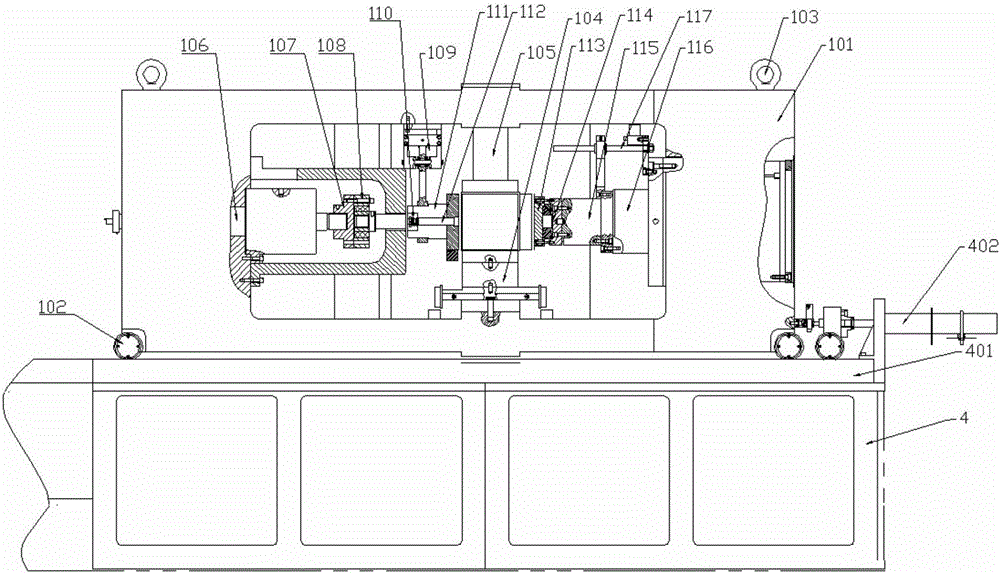

[0026] This embodiment provides a rock true triaxial test device that can be equipped with samples, the structure is as follows figure 1 , figure 2 As shown, it includes the X-direction support frame 4 and the Y-direction support frame 5 which are horizontally arranged and installed vertically to each other. The Z-direction support frame 6 is perpendicular to the X-direction support frame 4 and the Y-direction support frame 5. The X-direction loading worktable 1 is installed on the frame 4, and the X-direction loading workbench 1 can slide along the setting direction of the X-direction support frame 4. The Y-direction loading workbench 2 is installed on the Y-direction support frame 5, and the Y-direction loading work The table 2 can slide along the setting direction of the Y-direction support frame 5, and the Z-direction support frame 6 is equipped with a Z-direction loading workbench 3, and the Z-direction loading workbench 3 can slide along the setting direction of the Z-d...

Embodiment 2

[0033] This embodiment provides a rock true triaxial test method that can be equipped with samples, including the following specific steps:

[0034] Step (1), check whether the lines and pipelines are well connected and carry out debugging;

[0035] Step (2), push the Y-direction loading frame 213 by driving the Y-direction support frame pushing device 212, and push the Y-direction loading worktable 2 into the Z-direction loading workbench 3;

[0036] Step (3), assemble the sample into a sample assembly according to the requirements, move the rock sample installation trolley 7 back to the branch slide rail on the side of the X-direction support frame 4, and install it on the rock sample installation trolley 7, and then put the rock sample installation trolley The rock sample installation trolley 7 with the sample assembly is pushed into the X-direction loading frame 101 through the branch slide rail;

[0037] Step (4), together with the rock sample installation trolley 7, pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com