Fiber grating temperature-humidity sensor package structure

A temperature and humidity sensor, humidity sensor technology, applied in the direction of instruments, measuring devices, measuring instrument components, etc., to achieve the effect of speeding up the response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

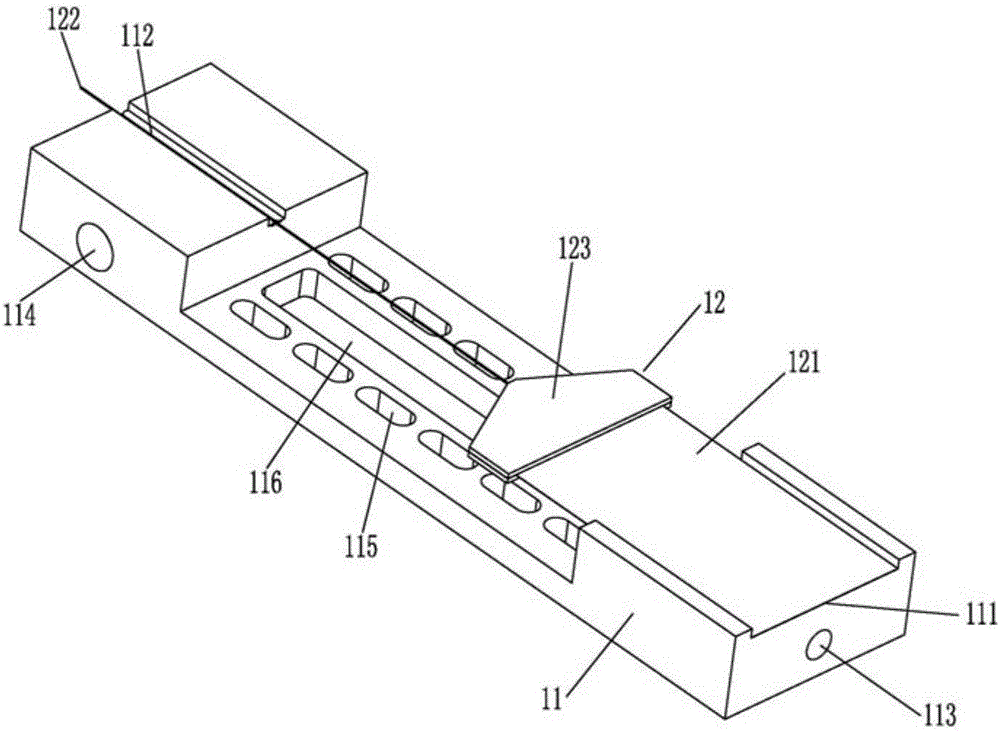

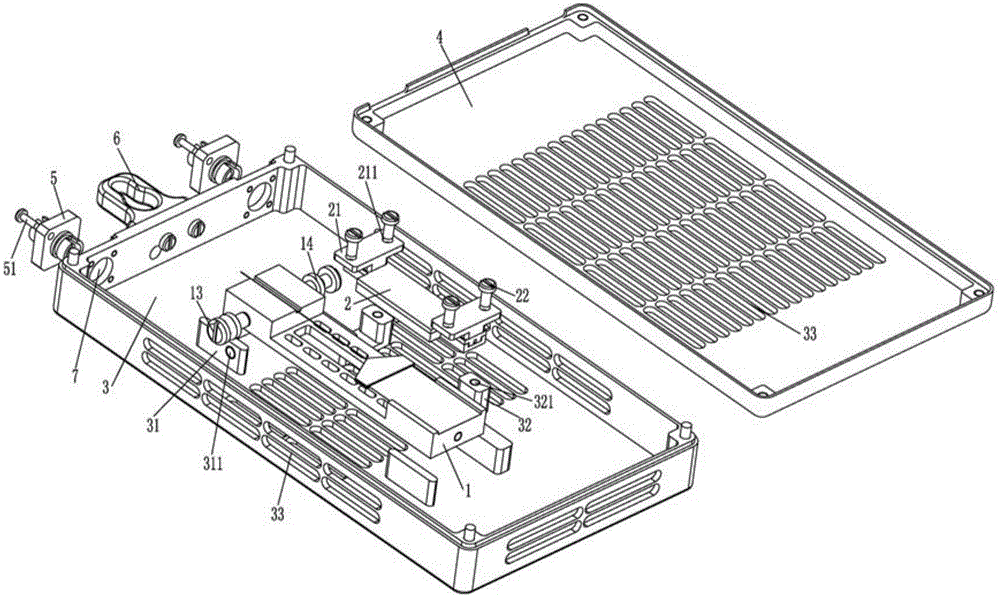

[0044] The diameter of the optical fiber engraved with the grating of the present invention is 125 μm, and the length of the grating area is 6mm-10mm.

[0045] The film 121 uses a polymer moisture-sensitive material.

[0046] The surface of the wide groove 111 and the surface of the narrow groove section are both rough surfaces.

[0047] The length of the humidity sensor bracket 11 is 90mm-110mm, the width is not less than 22mm, and the height is 6mm-9mm. The height of the wide groove section and the narrow groove section are the same, and both are not more than 6mm. The length of the wide groove section and the narrow groove section are the same, both 10mm- 20mm.

[0048] The length of the film 121 is 45 mm-65 mm, the width is not less than 20 mm, and the thickness is 20 μm-30 μm, and the film 121 matches the wide groove 111.

[0049] An example of the present invention is:

[0050] The diameter of the grating-engraved fiber 122 is 125 μm, and the length of the grating area is 10 mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com