Anti-scaling trinity oil well pump

A three-in-one, oil well pump technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as vibration of sucker rod strings, pump stuck when shutting down, scraping and ring scale cannot be removed in time, etc. , to achieve the effect of preventing the scale from sticking to the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

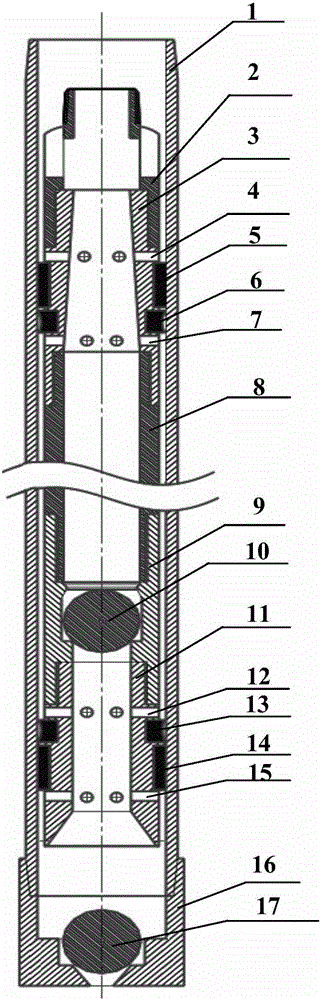

[0010] Specific embodiments: The present invention will be further described below in conjunction with the accompanying drawings: it consists of a pump barrel 1, an oil outlet joint 2, an upper anti-scaling short-circuit 3, an upper scraping ring 5, an upper anti-scaling ring 6, an alloy plunger 8, Swimming ball seat 9, ball ball 10, lower anti-scaling short 11, lower anti-scaling ring 13, lower scraping ring 14, fixed ball seat 16 and fixed ball 17; pump cylinder 1 It is threadedly connected with the fixed valve seat 16, and the fixed valve ball 17 is placed in the fixed valve seat 16. The bottom of the oil outlet joint 2 is connected with the upper anti-scaling short-circuit 3 thread connection, and the upper and lower ends of the alloy plunger 8 are respectively short-circuited with the upper anti-scaling 3. Swimming valve seat 9 is threaded, the bottom of the swimming valve seat 9 is threaded, and the lower anti-scaling short circuit 11 is placed, and the swimming valve sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com