Side-top arch collapse cavity supporting system and method for super-large-section tunnel in plateau region

A technology with extra-large section and large section, which is applied in the field of tunnel support system, can solve the problems of unstable support, long construction period, and high construction pressure, and achieve the effect of simple on-site construction, saving construction period, and stable support period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

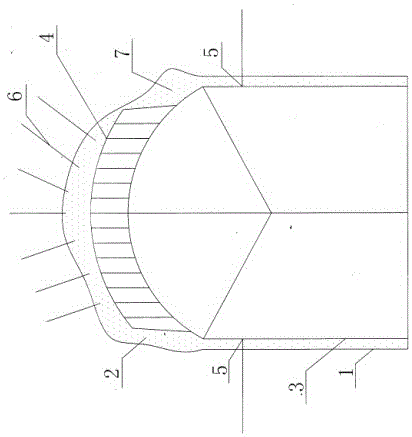

[0016] A side arch collapse cavity support system for extra-large-section tunnels in the plateau area. Excavating a super-large-section tunnel body forms a large-section excavation hole profile 1. When the surrounding rock of the hole body is loose, the hole body will be excavated at a large section There is a vault collapse cavity 2 at the vault of profile 1. When the vault collapse cavity 2 has a large area and deep depth, it will seriously affect the initial support of the excavated cave body, so the traditional primary support measures are adopted. The expected effect cannot be achieved, and new hidden dangers of landslides will occur; the initial support concrete is first sprayed on the rock surface of the large-section excavation cave body outline 1 and the rock surface of the vault collapse cavity 2, and the vault cavity 2 The anchor cable support system 5 is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com