Platform system for vertical shaft heading machine

A technology for roadheaders and shafts, which is applied to shaft equipment, well sinking, shaft lining, etc., can solve problems such as complex and difficult design, and achieve the effects of shaft wall expansion, easy maintenance, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

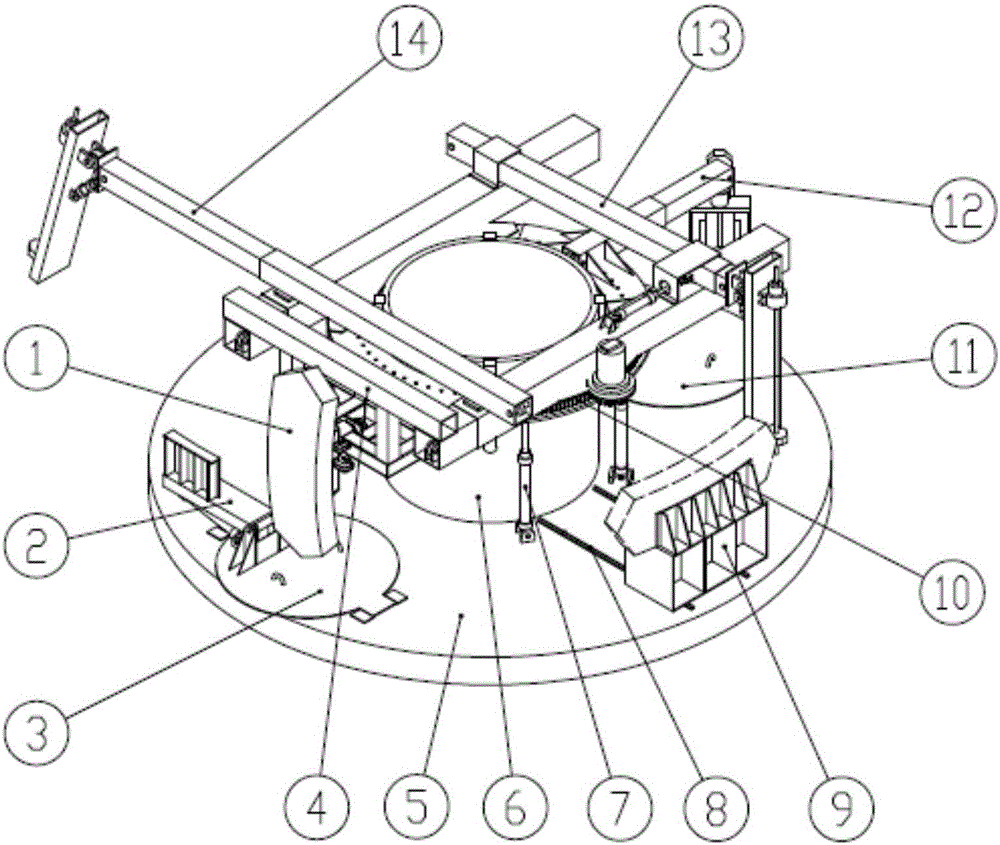

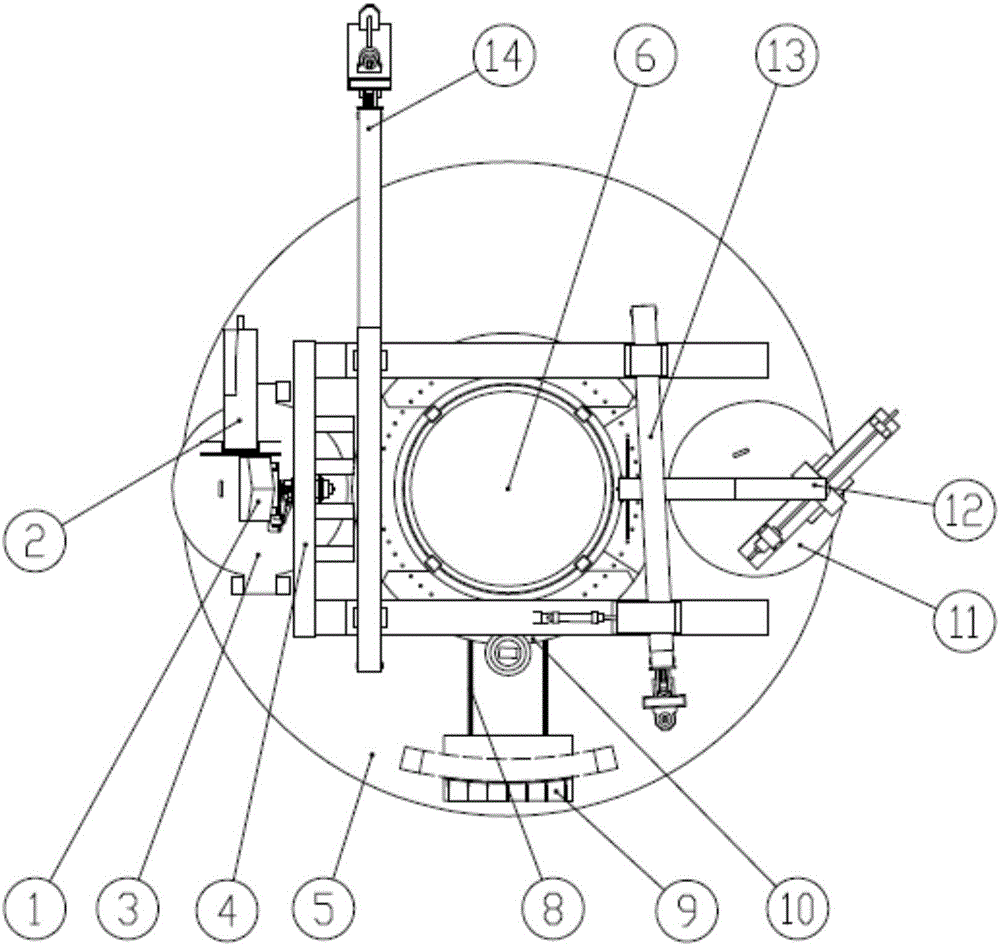

[0029] The platform 5 is circular, and the center of the platform 5 is provided with a cylindrical column 6, and tank holes are symmetrically arranged on the platforms 5 on both sides of the column 6, and a first well cover 3 and a second well cover 11 are correspondingly arranged above the symmetrical tank holes. One side of a manhole cover 3 is provided with a segment limit and straightening tool 2, and a rotary mechanism 10 is provided on the upper periphery of the column 6. At least four lifting mechanisms 7 are evenly distributed between the rotary mechanism 10 and the platform 5. The shaft segment assembly machine system 4 adopts U-shaped structure, the shaft segment assembly machine system 4 is arranged on the rotary mechanism 10, and the shaft bolt drilling system 12 is arranged on the rotary mechanism 10 corresponding to the U-shaped opening of the shaft segment assembly machine system 4, and the vertical shaft segment assembly machine system The first shaft advanced d...

Embodiment 2

[0031] After the segment 1 is transported from the ground to the platform system, the segment limit and straightening tool 2 on the upper side of the first manhole cover 3 gradually contacts the segment 1, and the segment limit and straightening tool 2 limits the position of the segment 1, so that Segment 1 is perpendicular to the center of the first manhole cover 3. Install the segment 1 on the middle side of the U-shaped shaft segment assembly machine system 4, then the segment limit and straightening tool 2 returns to its original position, and the shaft segment is assembled. The machine system 4 controls the height of the segment 1 by adjusting the height of the lifting mechanism 7, and controls the working position of the segment 1 by rotating above the rotary mechanism 10. The vertical shaft segment assembly machine system 4 installs the segment 1 to the required position. After positioning, the shaft segment assembly machine system 4 returns to its original position, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com