A device and method for testing the soil extrusion effect of pipe piles

A test device and pipe pile technology, which is applied in the direction of foundation structure test, construction, foundation structure engineering, etc., can solve the problems that the evolution of soil layer properties cannot be obtained, and achieve the purpose of overcoming the evolution of soil layer properties, easy replacement of parts and cleaning, and soil Plug stress controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

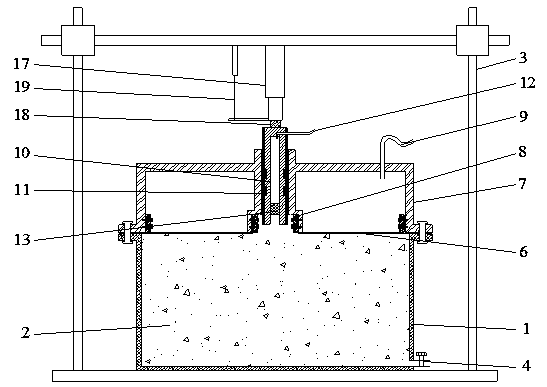

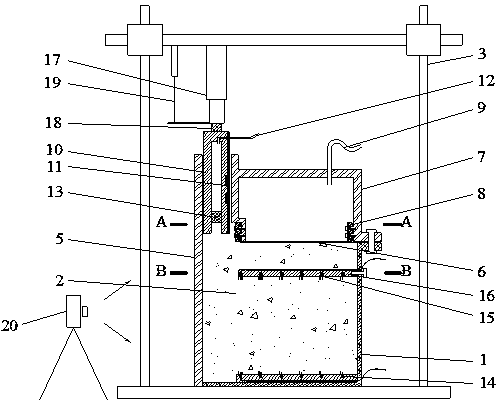

[0043] Such as Figure 1~4 As shown, a pipe pile soil extrusion effect test device includes a model bucket 1, a reaction frame 3, an air pressure chamber 7, a model pipe pile 10, a tempered glass plate 5, a Y-shaped base 16, an electro-hydraulic servo jack 17, a bending Meta-testing rig and high-resolution camera20;

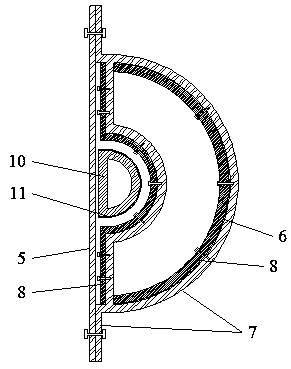

[0044] The model bucket 1 is a steel semicircular cylinder structure, a strip-shaped base is arranged radially at the center of the bottom of the bucket, a Y-shaped base 16 is arranged on the top of the model bucket 1, and an air pressure chamber 7 is arranged above the model bucket 1 ;

[0045] The air pressure chamber 7 is a concentric semi-circular cylinder structure with an opening at the bottom. The outer edge of the air pressure chamber 7 coincides with the outer edge of the model bucket 1. The bottom surface of the air pressure chamber 7 is sealed with a latex film 6. The top is provided with an air injection hole 9 for the air pressure chamber. The cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com